On-line monitoring device for mechanical splices of entire core rubber belt

A joint online and monitoring device technology, applied in conveyor control device, transportation and packaging, conveyor objects, etc., can solve the problem of unrealistic manual detection of mechanical joints, and achieve convenient and fast installation and maintenance, easy installation, and reduced burden. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below with reference to the accompanying drawings.

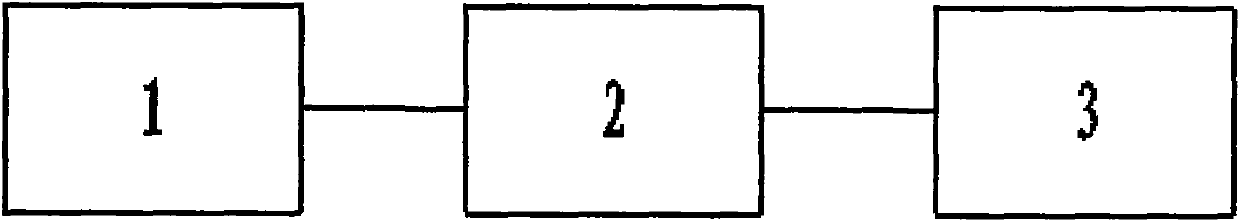

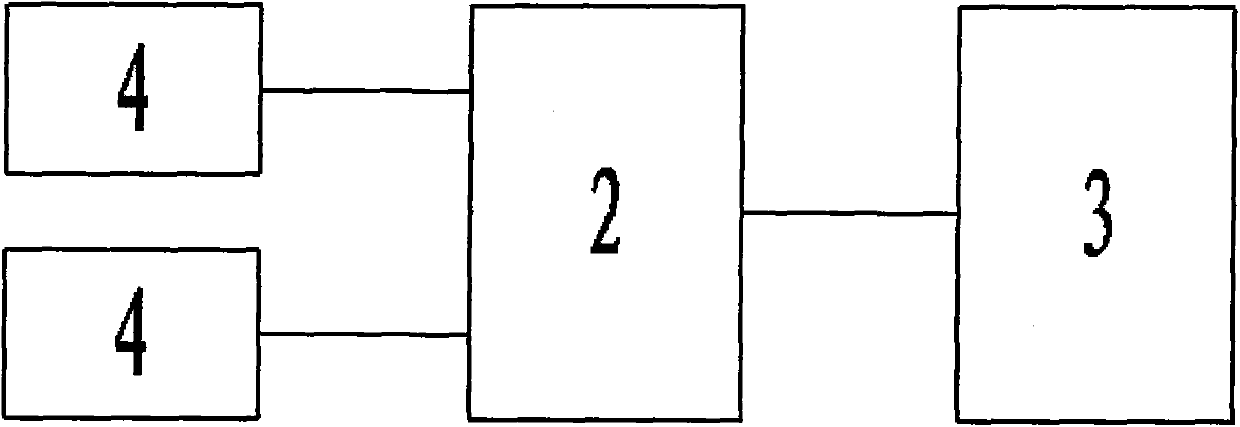

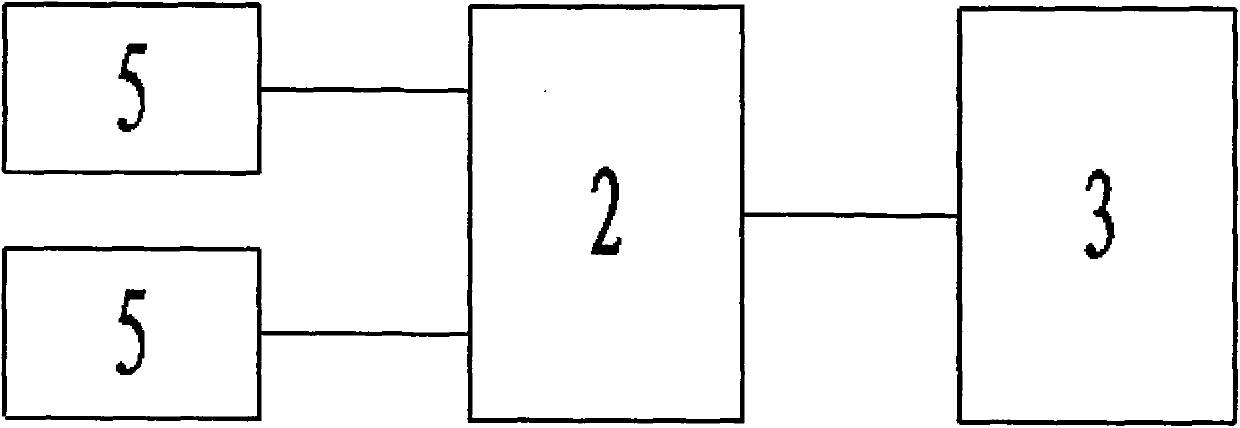

[0015] Such as figure 1 As shown, the on-line monitoring device for the mechanical joint of the whole core adhesive tape of the present invention includes an acquisition unit 1, a control unit 2 and a computer 3, wherein the acquisition unit 1, the control unit 2 and the computer 3 are connected in sequence. The acquisition unit 1 mentioned above may be a camera, which is used to take pictures of the front and back belt conveyors, and transmits the image and video signals to the control unit 2, and the acquisition unit 1 may be a metal detection sensor, which is used to detect the conductivity of metal and magnetic permeability, the control unit 2 includes a power module, a signal transfer module and a power servo module, the power module provides the required power for each part, and the video conversion module converts the signal collected by the acquisition unit 1 int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com