A kind of preparation method of bulk flame retardant polystyrene by emulsion method

A technology of polystyrene and emulsion method, which is applied in the field of preparation of flame-retardant polystyrene by emulsion method, can solve the problems of fire hazards, life and property, impact on mechanical strength, and difficulty in uniform dispersion, so as to overcome the decline in mechanical properties and benefit The effect of environmental protection and easy availability of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

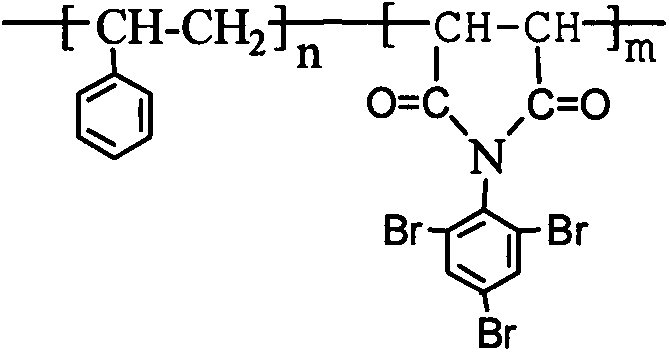

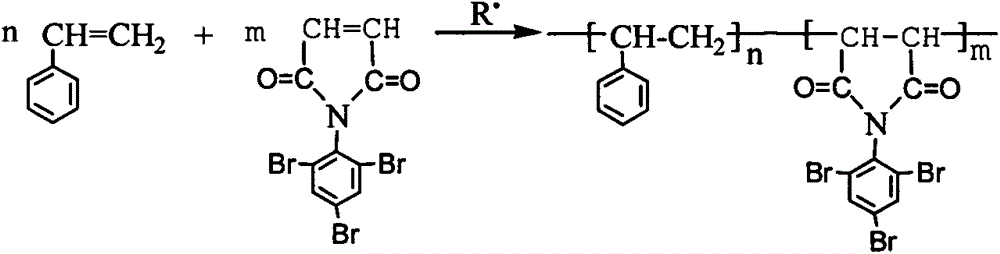

Method used

Image

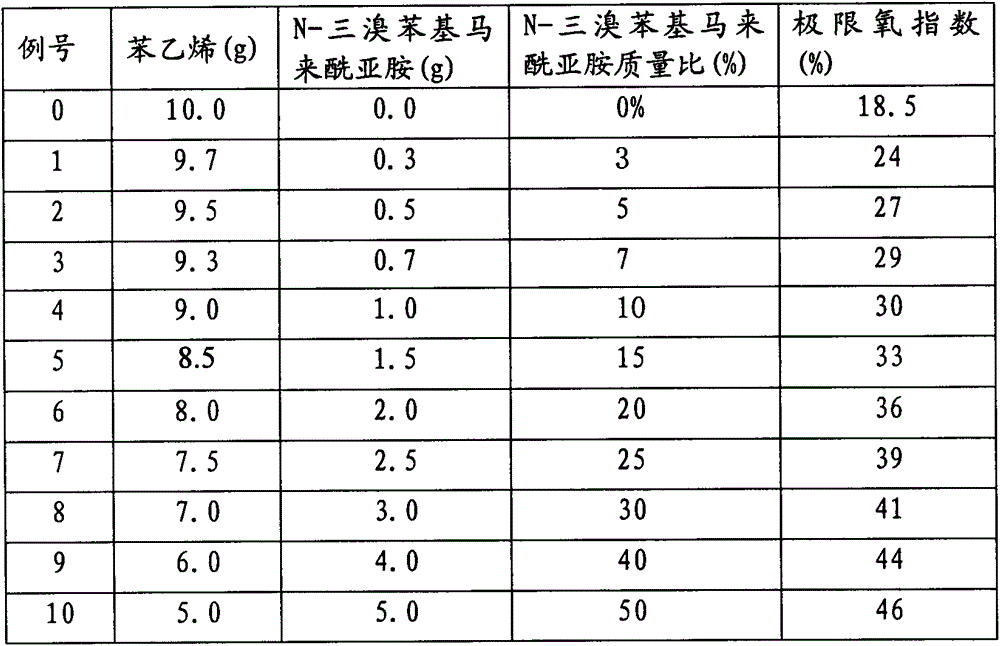

Examples

Embodiment 1

[0026] Example 1 Add distilled water 50ml, 10% polyvinyl alcohol solution 1.5ml, 10% sodium lauryl sulfate solution 1.0ml, styrene 9.7g, N -Tribromophenylmaleimide 0.3g, benzoyl peroxide 0.11g, start stirring, heat up to 90°C, keep warm for 5h, stop the reaction, stir, cool to room temperature, filter out the product particles, wash with water, After drying, a white granular bulk flame-retardant polystyrene is obtained with a yield of 94% and a glass transition temperature of 90°C.

Embodiment 2

[0027] Example 2 Add distilled water 50ml, 10% polyvinyl alcohol solution 1.5ml, 10% sodium lauryl sulfate solution 1.0ml, styrene 9.5g, N - 0.5g of tribromophenylmaleimide and 0.1g of benzoyl peroxide, start stirring, raise the temperature to 80°C, keep warm for 6h, stop the reaction, cool to room temperature under stirring, filter out the product particles, wash with water, After drying, a white granular bulk flame-retardant polystyrene is obtained with a yield of 97% and a glass transition temperature of 96°C.

Embodiment 3

[0028] Example 3 Add distilled water 50ml, 10% polyvinyl alcohol solution 1.5ml, 10% sodium lauryl sulfate solution 1.0ml, styrene 9.3g, N - Tribromophenylmaleimide 0.7g, 0.09g tert-butyl peroxybenzoate, start stirring, heat up to 70°C, keep warm for 7h, stop the reaction, stir, cool to room temperature, filter out the product particles, and water After washing and drying, white granular bulk flame-retardant polystyrene was obtained, with a yield of 96% and a glass transition temperature of 101°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com