Pipe and plate connection piece

A technology of tube-sheet connector and mouth tube, which is applied in soil protection, construction, infrastructure engineering and other directions, can solve the problems of large power loss and uneconomical construction methods, and achieves the effect of simple production and reduced construction costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Now in conjunction with the accompanying drawings, the technical solution of the present invention is further explained.

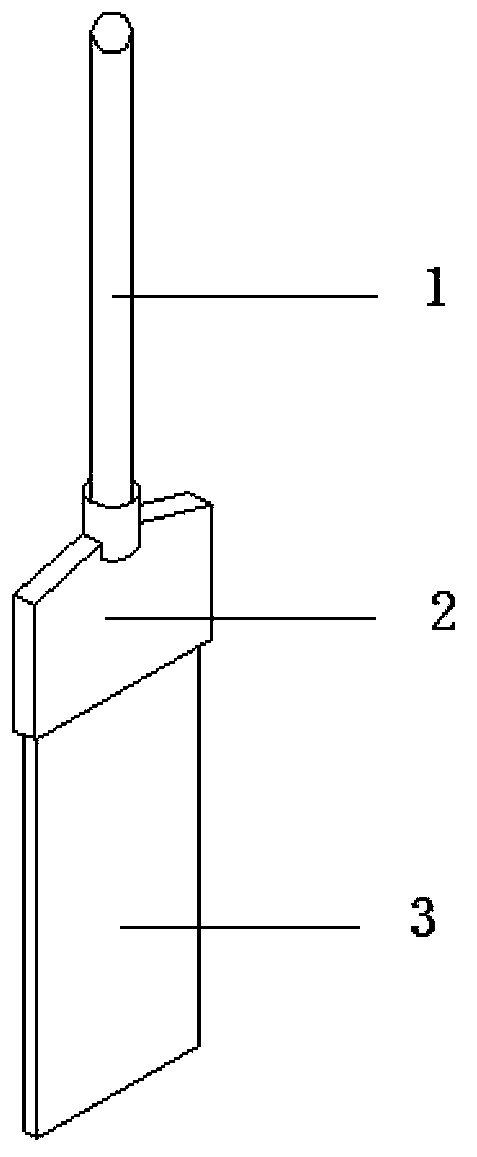

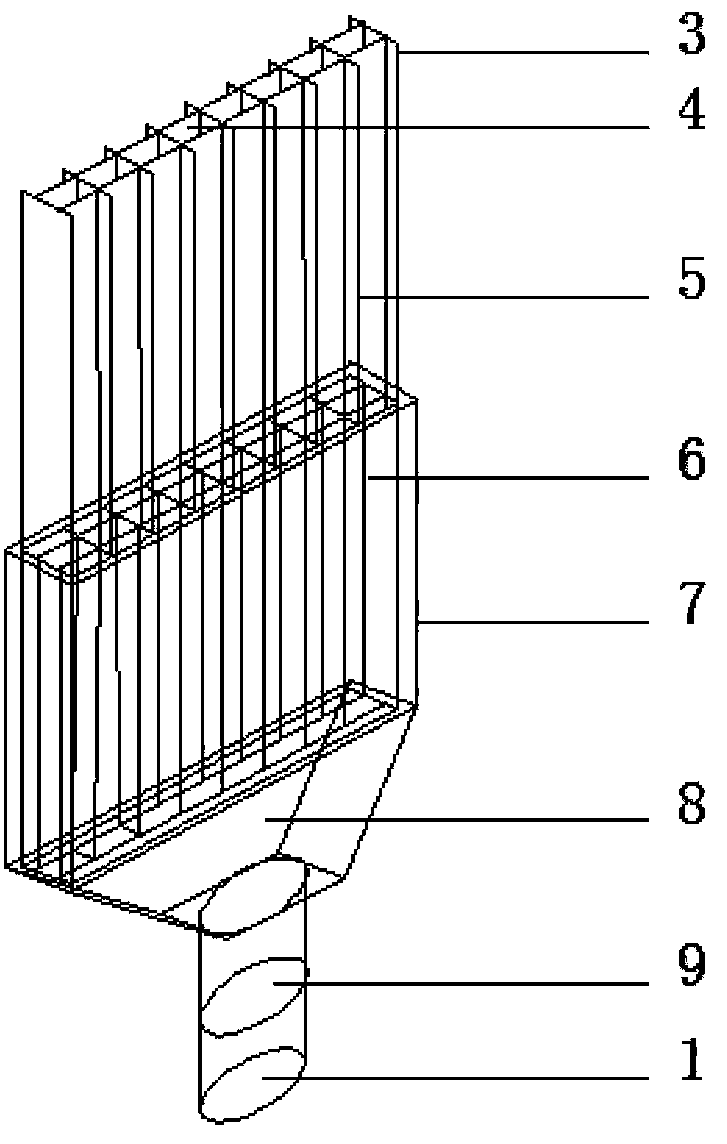

[0018] The main purpose of the tube-sheet connector as shown in the figure is to connect the vacuum pipeline branch pipe 1 and the air guide channel 4 of the pumping-type plastic drainage plate core plate with double drainage channels. The upper part of the tube-sheet connector has a connection with the vacuum pipeline branch Circular interface, the interface is provided with a one-way valve 9, the middle part is a cuboid cavity 8, the lower part of the cavity is a slot 7, a row of tapered square-mouth tubes 6 protrude from the slot, and the protruding tapered square-mouth tubes The number is consistent with the number of air guide holes in the core plate of the new plastic drainage plate. When the tube plate connector is connected to the drain plate 3, the air guide channel 4 of the drain plate is facing the square mouth tube 6 of the tube plate con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com