MEMS microphone structure and manufacturing method thereof

A manufacturing method and microphone technology, which are applied to electrostatic transducer microphones, sensors, electrical components, etc., can solve the problems of complex manufacturing process and packaging process, high cost, bulky volume, etc., and achieve the effect of improving anti-interference ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

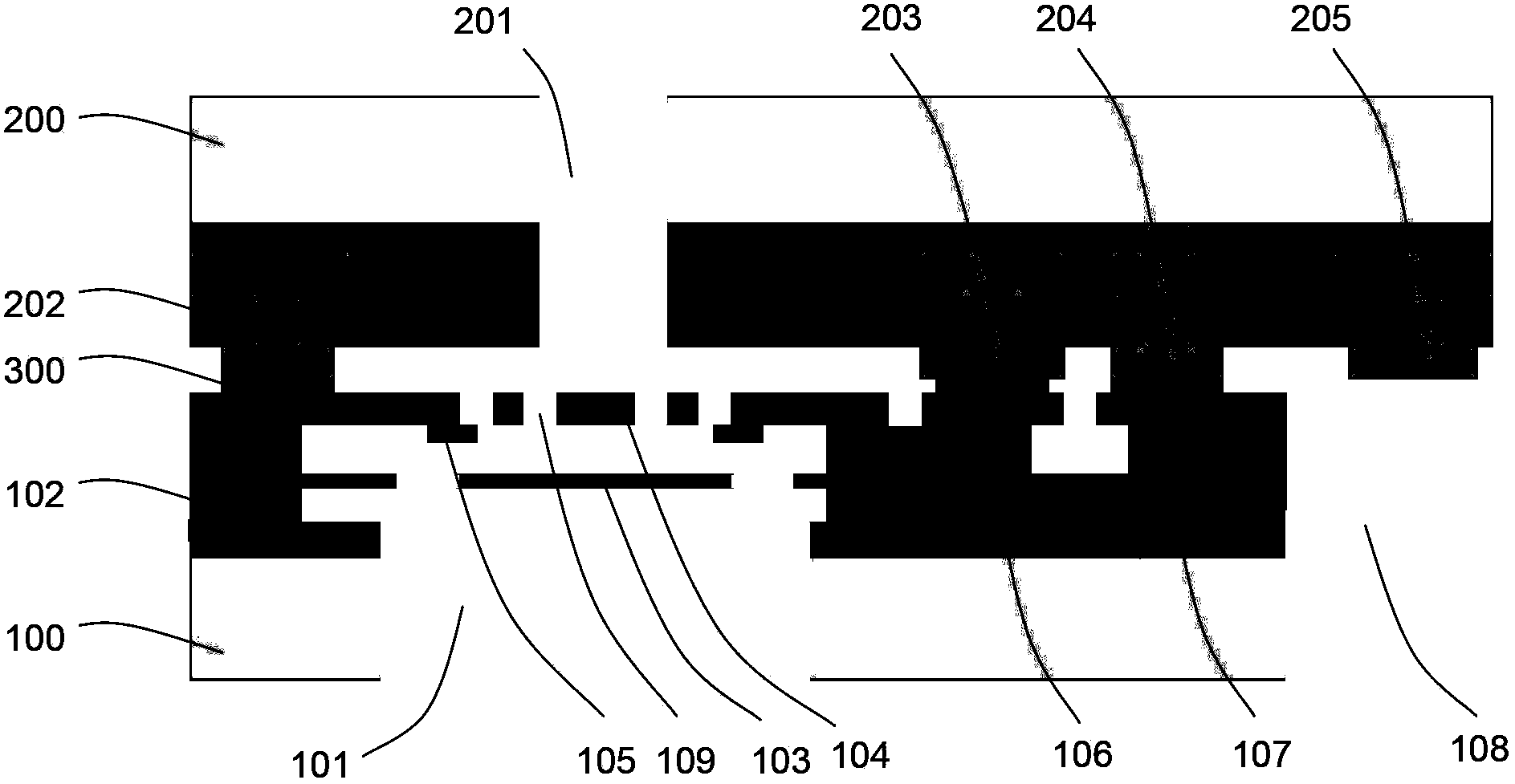

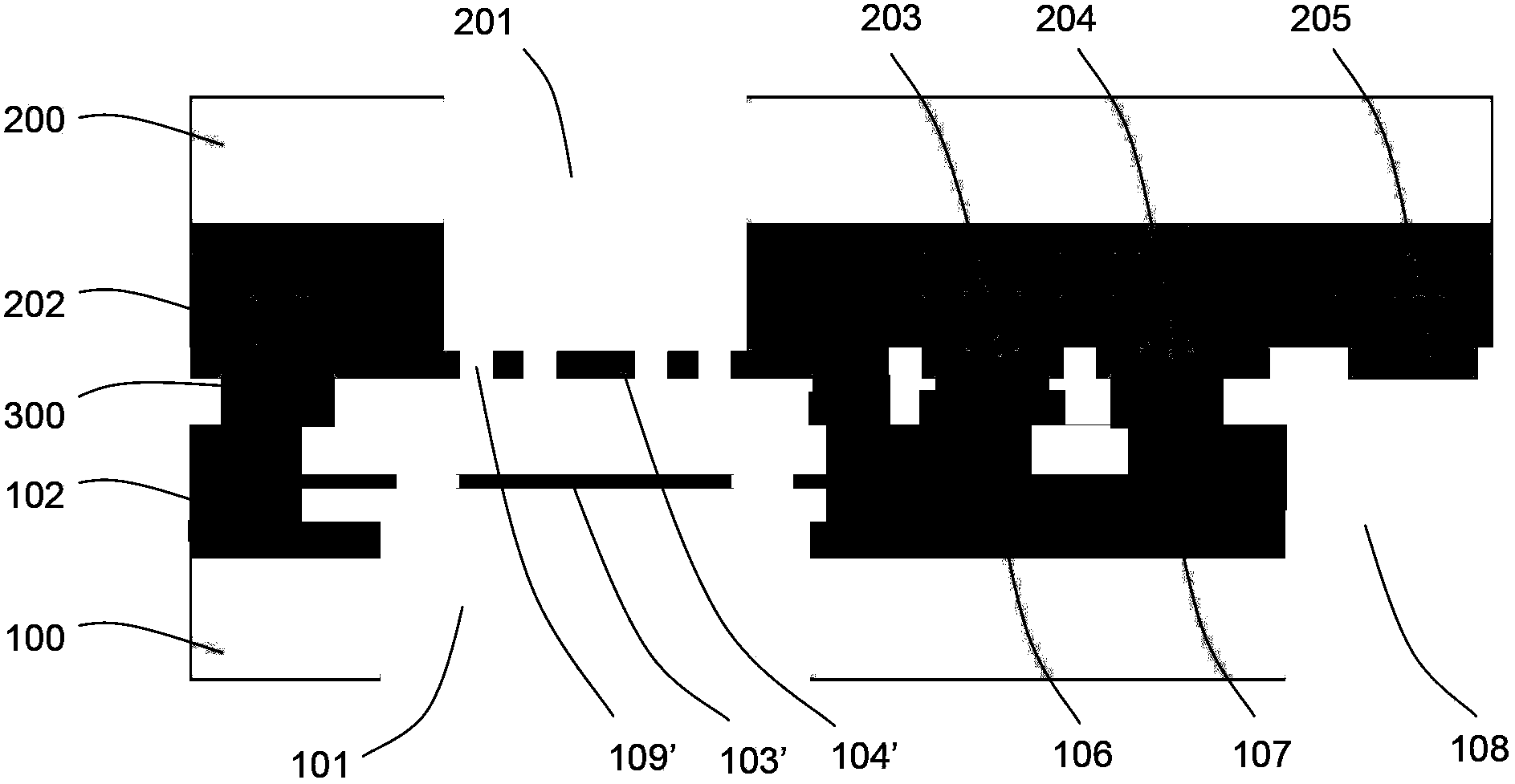

[0045] For the MEMS microphone structure of this embodiment, please refer to figure 1 ,include:

[0046] A first substrate 100, the first substrate has a first opening 101;

[0047]The first dielectric layer 102 and the first conductive structure layer on the first substrate 100, the first conductive structure layer includes a MEMS microphone assembly, a first conductive adhesive structure 106, and a first substrate conductive structure 107, wherein , the MEMS microphone assembly includes a sensitive film 103 and a fixed electrode 104 corresponding to the sensitive film 103, the first opening 101 corresponds to the sensitive film; the upper surface of the first conductive adhesive structure 106 is the first bonding surface; the first substrate conductive structure 107 penetrates through the first dielectric layer 102 and is connected to the first substrate 100;

[0048] The second substrate 200, the second substrate contains signal processing circuit elements ( figure 1 no...

Embodiment 2

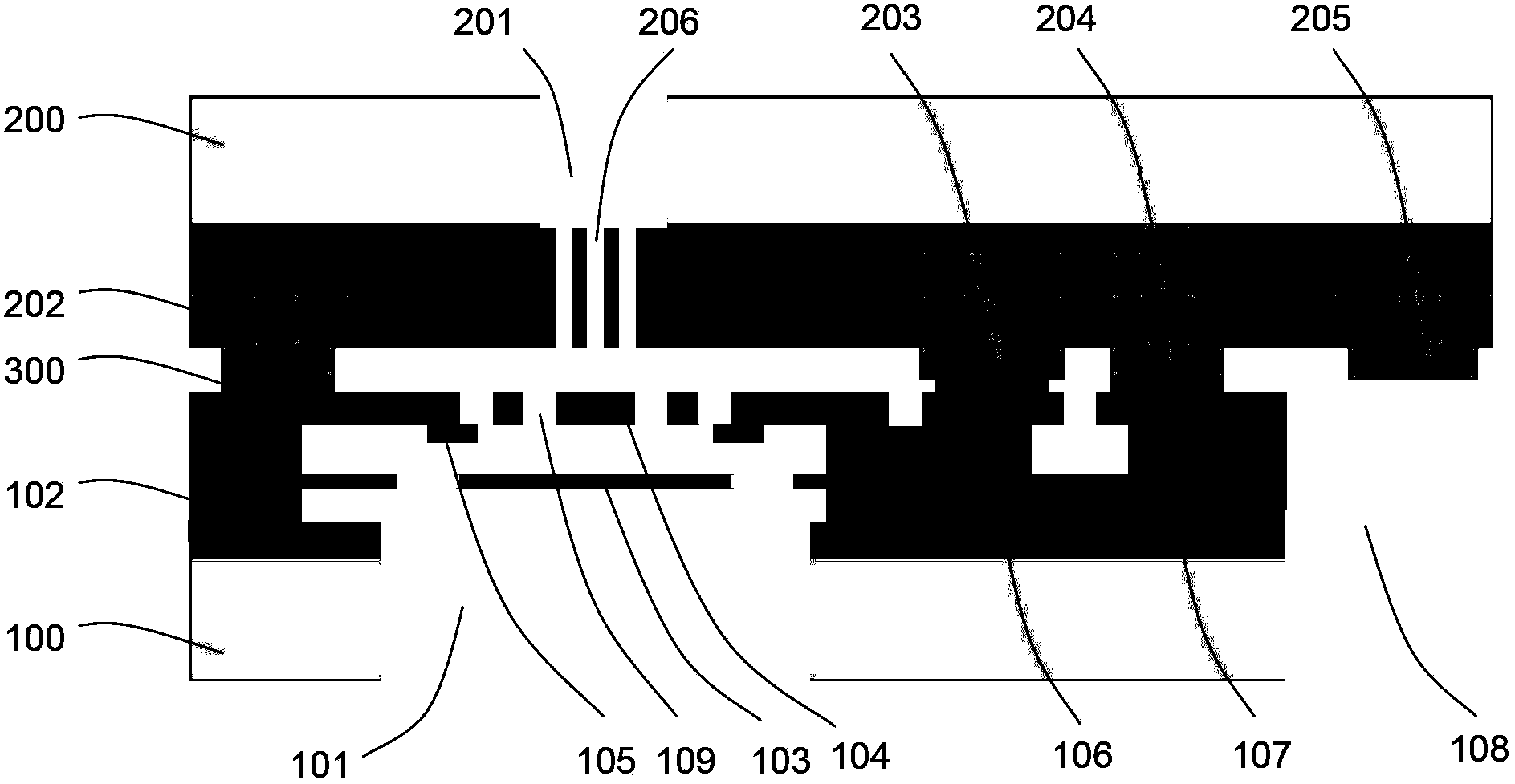

[0063] For the MEMS microphone structure of this embodiment, please refer to image 3 The difference between this embodiment and Embodiment 1 is that there is at least one through hole in the second dielectric layer 202 corresponding to the sensitive film 103 of the MEMS microphone component or the fixed electrode 104 corresponding to the sensitive film 103 206 , the second opening 201 of the second substrate 200 exposes the sensitive film 103 or the fixed electrode 104 through the through hole 206 . Other parts of the structure of the MEMS microphone in this embodiment are identical to those in Embodiment 1, and will not be repeated here.

[0064] In this embodiment, there is at least one through hole 206 in the second dielectric layer 202 corresponding to the sensitive film 103 or the fixed electrode 104 of the MEMS microphone assembly, so that a hole 206 remains above the sensitive film 103 or the fixed electrode 104. Part of the second dielectric layer, forming such a str...

Embodiment 3

[0067] On the basis of Embodiment 2, the MEMS microphone structure in this embodiment also includes a third conductive structure, see Figure 5 The difference between this embodiment and the second embodiment is that: there is a third conductive structure 207 in the second dielectric layer 202 corresponding to the sensitive film 103 of the MEMS microphone component or the fixed electrode 104 corresponding to the sensitive film 103 and at least one through hole 206 ′, the through hole 206 ′ passes through the second dielectric layer 202 and the third conductive structure 207 . Other parts of the MEMS microphone structure of the present embodiment are the same as those of the second embodiment ( image 3 ) are exactly the same and will not be repeated here.

[0068] Preferably, the third conductive structure is layered, and one or more surfaces of the layered third conductive structure are covered by the second dielectric layer, Figure 5 In the above, the third conductive str...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com