System and method for diagnosing and intelligently optimizing grinding processes

A process diagnosis and grinding technology, used in metal processing equipment, grinding machine parts, grinding/polishing equipment, etc., can solve problems such as unrealizable, limited quality, etc., to improve quality and precision machining technology. , the effect of reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

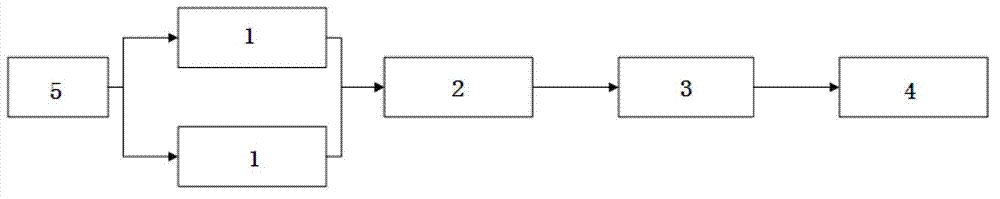

[0023] Such as figure 1 As shown, it discloses a grinding process diagnosis and intelligent optimization system. As shown in the figure: it includes sensor 1 (with power supply 5), data acquisition card 2, grinding process diagnosis system 3 and grinding process intelligent optimization system 4; wherein: the sensor 1 includes a power sensor and a displacement sensor, the sensor 1 is connected to the grinding process diagnosis system 3 through the data acquisition card 2, and the grinding process diagnosis system 3 is further connected to the grinding process intelligent optimization system 4.

[0024] In the present invention, the input information available to the grinding process diagnosis system 3 includes: machine tools, grinding wheels, workpiece materials, grinding process parameters and output signals of the data acquisition system. The collected sensor signals can be displayed on the computer in real time for on-site analysis, and can also be saved to the computer. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com