Colorized automatic-flow-into semi-flexible pavement mortar

A semi-flexible road surface and mortar technology, applied in the field of road mortar, can solve the problems of high price, difficult control of color uniformity, high transportation cost of liquid color paste, etc., and achieve the effect of improving stain resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

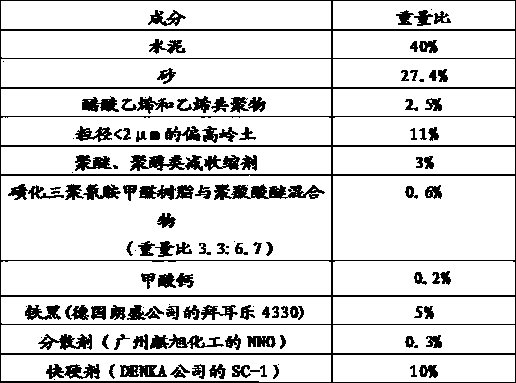

[0027] 1. The formula of black mortar

[0028]

[0029] 2. Mortar performance test:

[0030] Mix the components of the above formula, add 23.5% of the total amount of water in the mortar, and use a continuous mixer to stir on site to obtain road mortar. The road mortar has reached final setting after 8 hours of curing. The performance test results of the mortar are shown in Table 1:

[0031] Table 1

[0032]

Embodiment 2

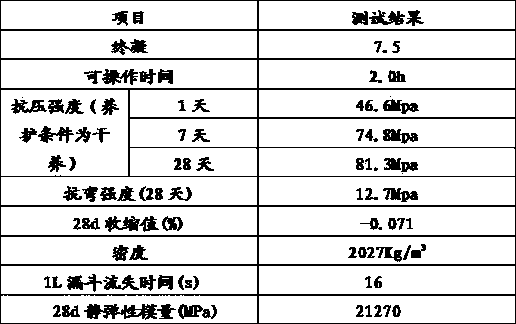

[0034] 1. The formula of red mortar

[0035]

[0036] 2. Mortar performance test

[0037] Mix the components of the above formula, add 23% water of the total amount of mortar, and use a continuous mixer to stir on site to obtain road mortar. The road mortar has reached final setting after 8 hours of curing. The performance test results of the mortar are shown in Table 2:

[0038] Table 2

[0039]

Embodiment 3

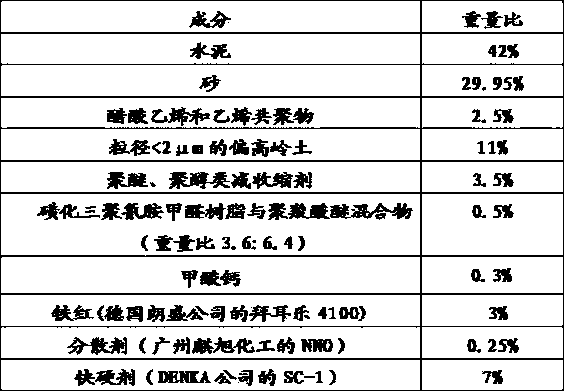

[0041] 1. Formula of yellow mortar

[0042]

[0043] 2. Mortar performance test

[0044] Mix the components of the above formula, add 22.5% of the total amount of water in the mortar, and use a continuous mixer to stir on site to obtain road mortar. The road mortar has reached final setting after 8 hours of curing. The performance test results of the mortar are shown in Table 2:

[0045] Table 2

[0046]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com