Tie bar for supporting system in high-rigidity integral prestressed fabricated foundation pit support

A foundation pit support and support system technology, applied in the direction of infrastructure engineering, excavation, construction, etc., can solve the problems of non-reusable, low support rigidity, difficult to control deformation, etc., to reduce corrosion, ensure safety, ensure The effect of intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

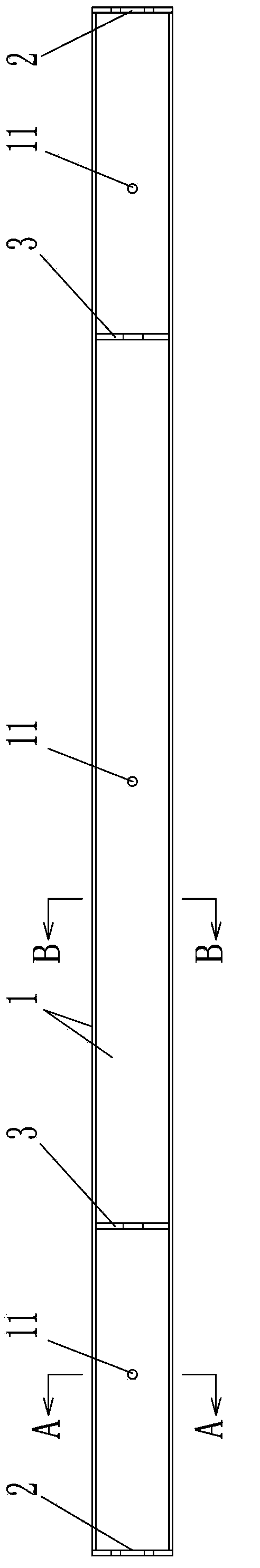

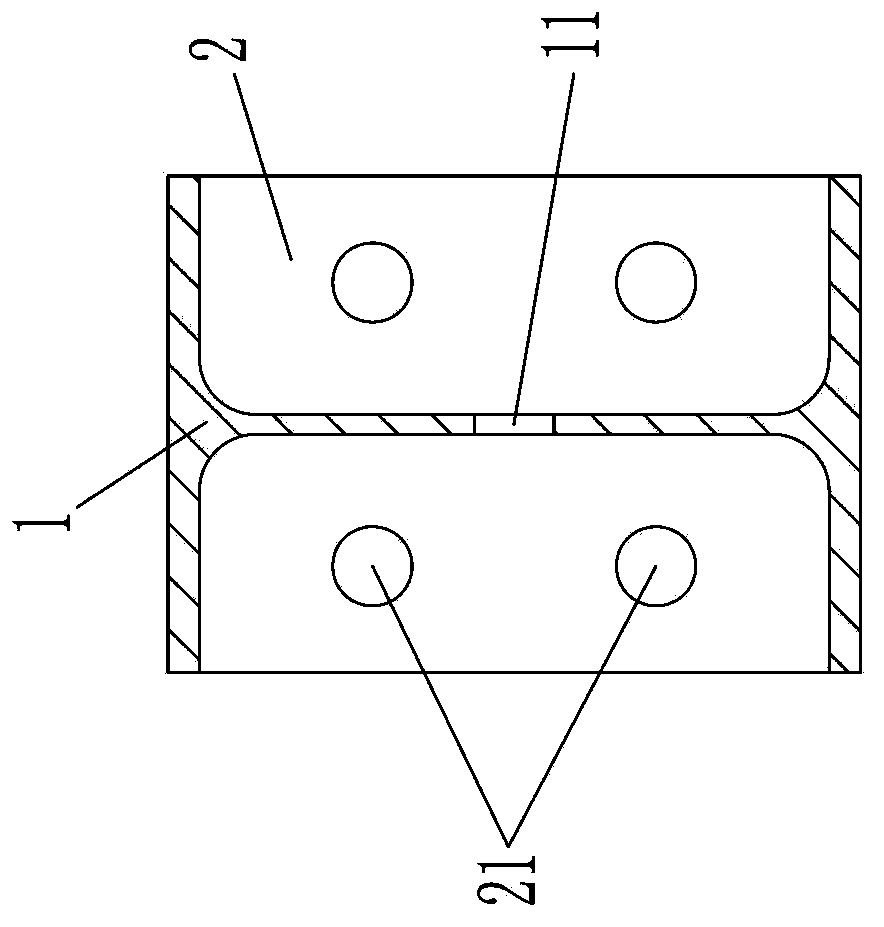

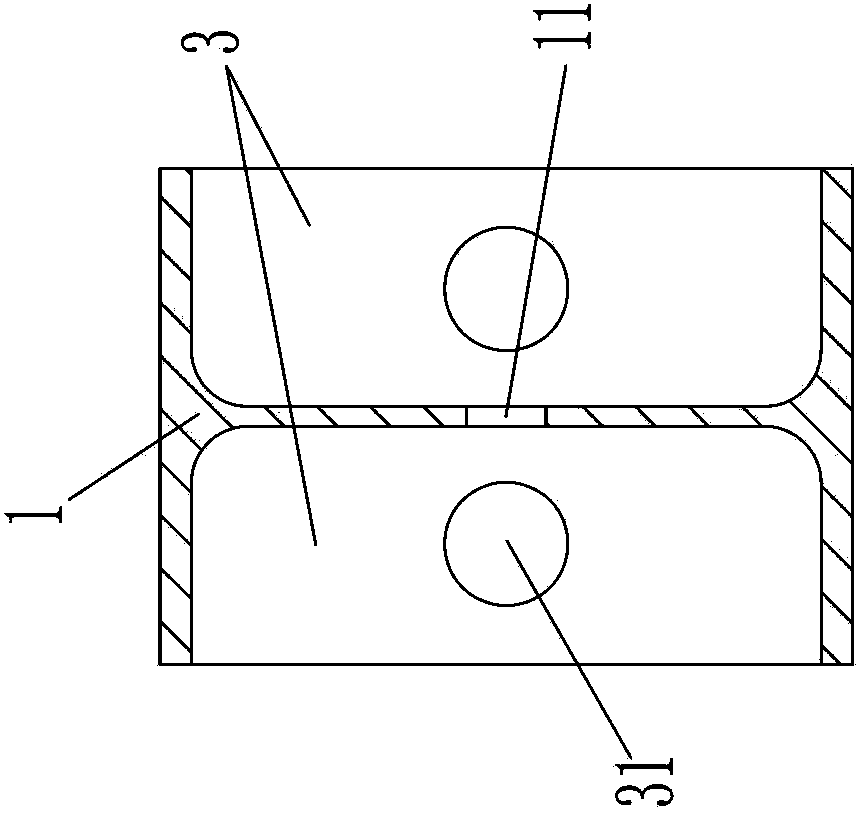

[0015] like figure 1 , figure 2 , image 3 , Figure 4 The tie rods for the high-rigidity overall prestressed assembled foundation pit support inner support system shown include long rod-shaped H-shaped steel 1, and the two ends of the H-shaped steel 1 are welded and fixed to a rectangular flange plate 2, and the flange plate 2 is fixed. Four connection holes 21 are provided, and the four connection holes 21 are divided into two rows up and down, and each row is set up one above the other. Two to four lug plates 3 are arranged in the side groove of the H-shaped steel 1, and the rectangular suspension The three sides of the lug plate 3 are respectively welded and fixed to the web plate and the wing plate of the H-shaped steel 1. The lug plate 3 has a hanging hole 31. The side groove of the H-shaped steel 1 is divided into multiple sections by the lug plate 3. Each section At least one drainage hole 11 is opened on the web of the H-shaped steel 1 .

[0016] In this embodime...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com