High-temperature and high-pressure reaction kettle electrode and on-line monitoring method with same

A high-temperature, high-pressure, reactor technology, which is applied in the field of electrical measurement, can solve problems such as weak electrochemical response, no high-temperature resistance of oil, high-voltage electrodes, and inability to directly measure electrical parameters on-line during oil processing, so as to improve the safety factor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings.

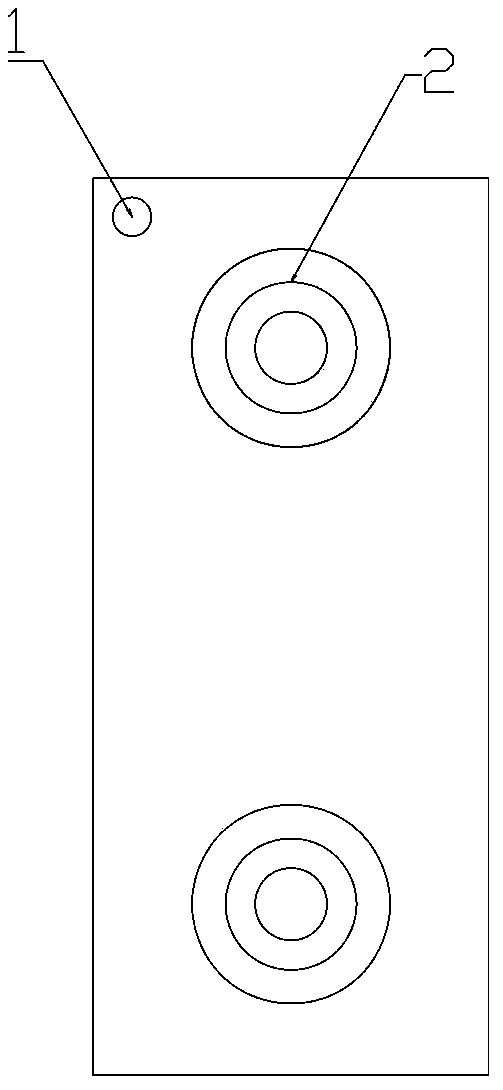

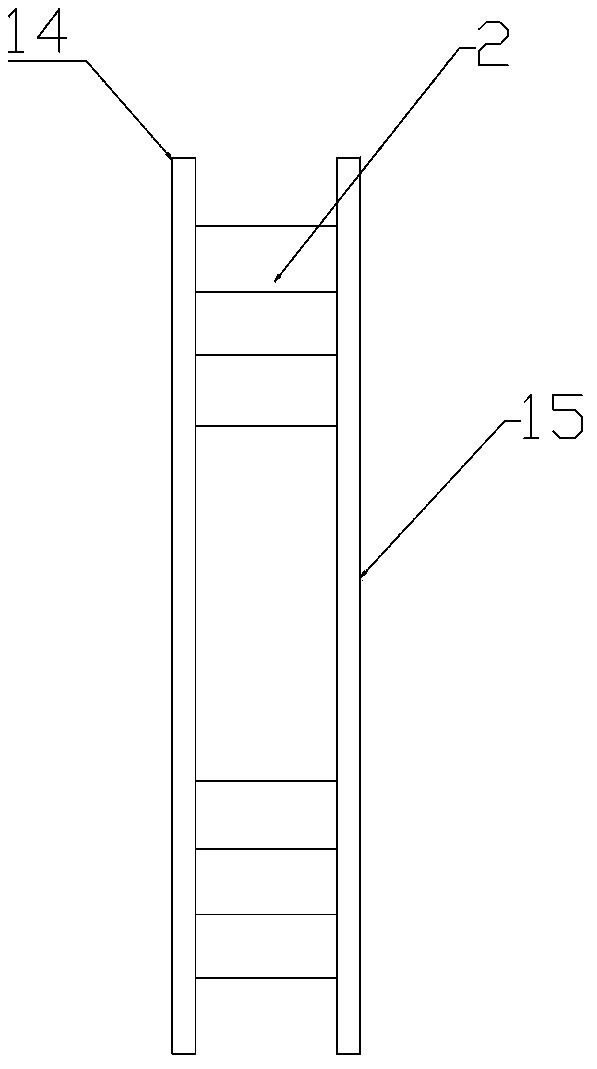

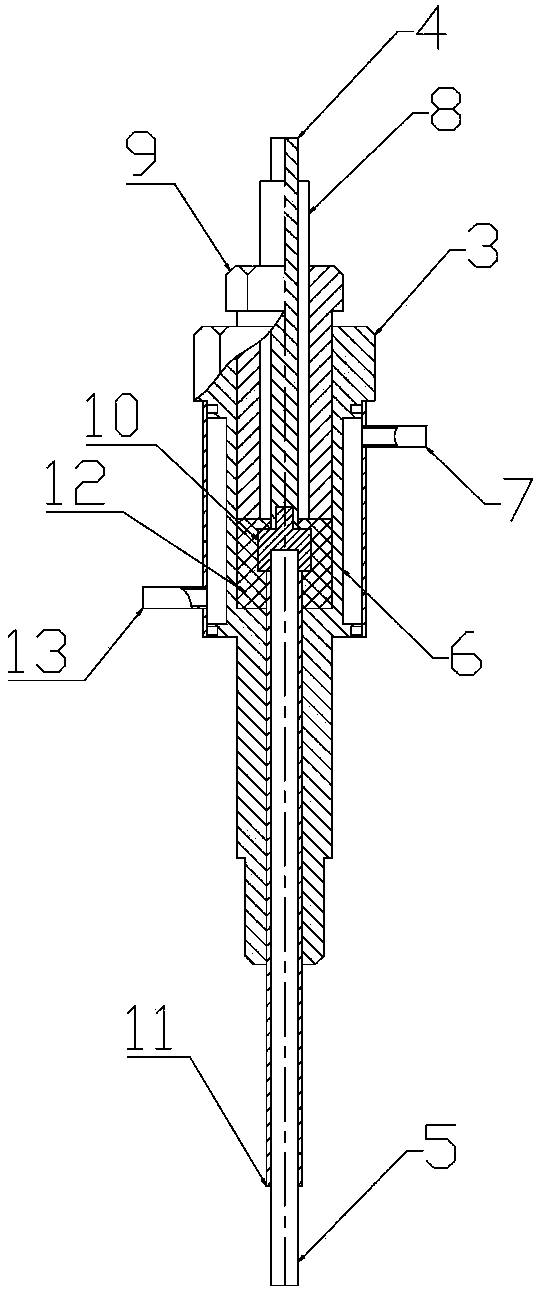

[0024] An electrode for a high-temperature and high-pressure reactor, including an electrode bracket, an electrode plate, and an electrode terminal 16. The electrode bracket is installed in the reactor, the electrode plate is installed on the electrode bracket, and the electrode plate is fixed firmly. No shaking, the electrode plate includes the left electrode 14 and the right electrode 15. Due to the high requirements on the conductivity, high temperature resistance and high pressure resistance of the material in the reactor, it needs to withstand the high temperature of 500 ℃ and the high pressure of 25MPa, and at the same time To resist the erosion of reactive gases such as hydrogen and nitrogen, the electrode plates are made of stainless steel, copper, aluminum and other materials. There are two electrode terminals 16, which are installed on the lid of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com