Method for automatically identifying and positioning coordinates of image point of artificial mark in camera calibration control field

A technology for controlling signs and positioning methods, which is applied in image enhancement, image analysis, image coding, etc., and can solve problems such as automatic recognition and high-precision measurement of image square coordinates of difficult mark points, complicated recognition process, and complicated calculation steps.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

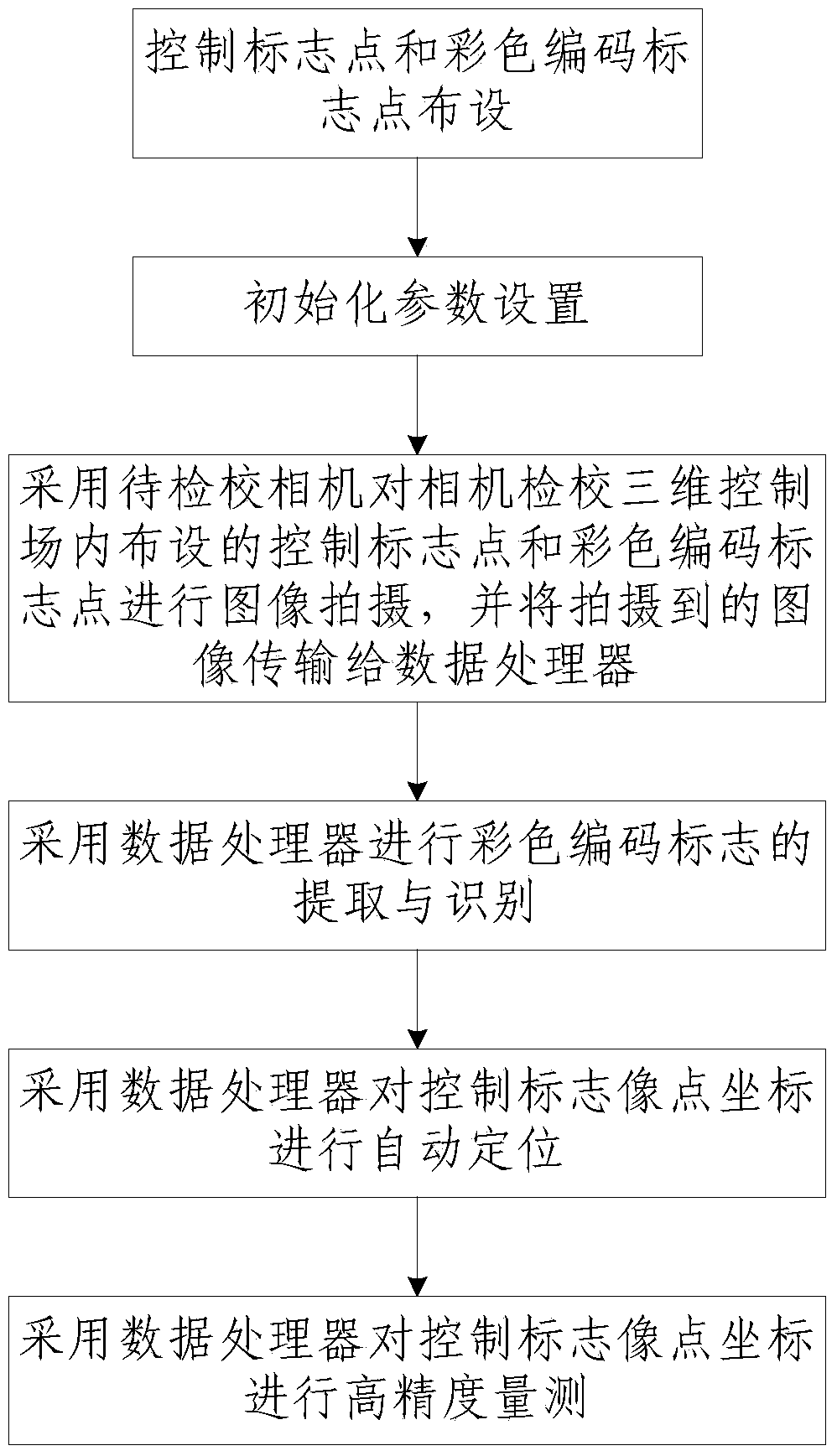

[0063] Such as figure 1 As shown, the method for automatically identifying and locating the image point coordinates of artificial signs in the camera calibration control field of the present invention includes the following steps:

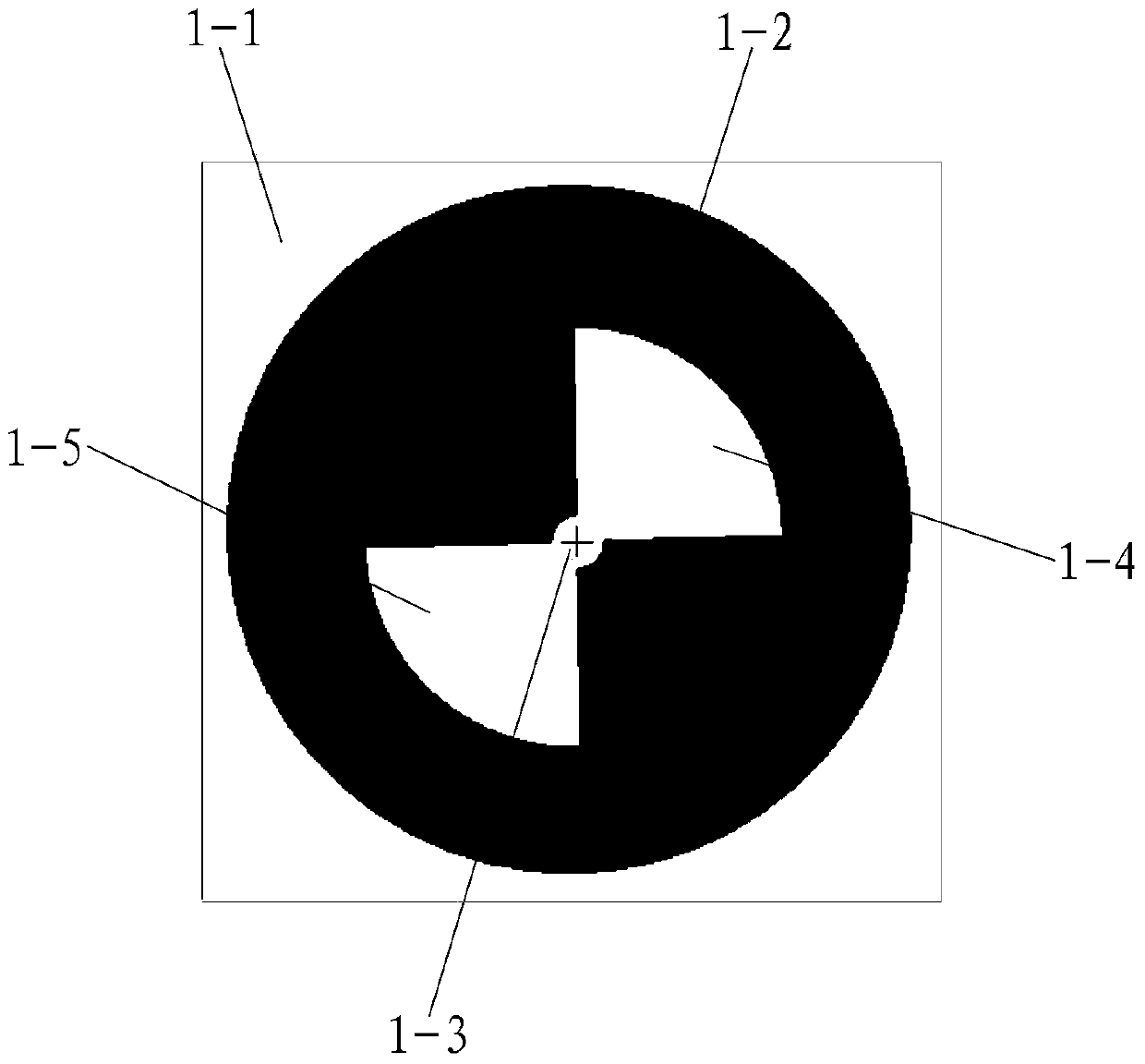

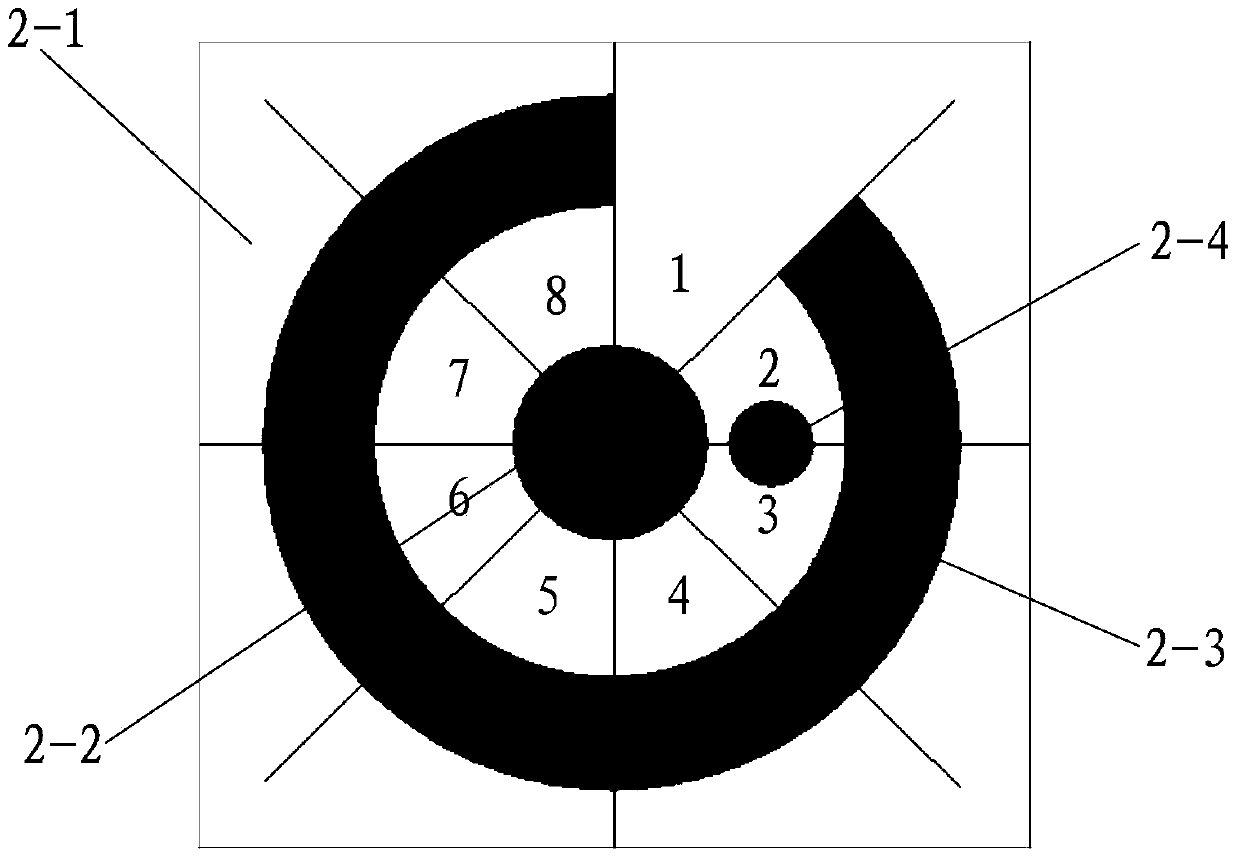

[0064] Step 1. Arrangement of control signs 1 and color-coded signs 2: a plurality of control signs 1 and a plurality of color-coded signs 2 with different codes are arranged in the three-dimensional control field for camera calibration; among them, such as figure 2 As shown, the control sign 1 includes a white base plate 1-1 of the control sign and a black outer circle 1-2 arranged on the white base plate 1-1 of the control sign. The center position of the black outer circle 1-2 is provided with a The black outer circle 1-2 is concentric with the white central circle 1-3, and the two sides of the white central circle 1-3 are provided with a white and mutually symmetrical first fan-shaped 1-4 and a second fan-shaped 1-5. The edge of a sector 1-4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com