Self-adaptive sectional driving DC-DC (Direct Current to Direct Current) converter

A DC-DC, segmented drive technology, applied in the direction of converting DC power input to DC power output, instruments, adjusting electrical variables, etc., can solve the problems of power tube switching frequency changes, limited application, etc., to achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

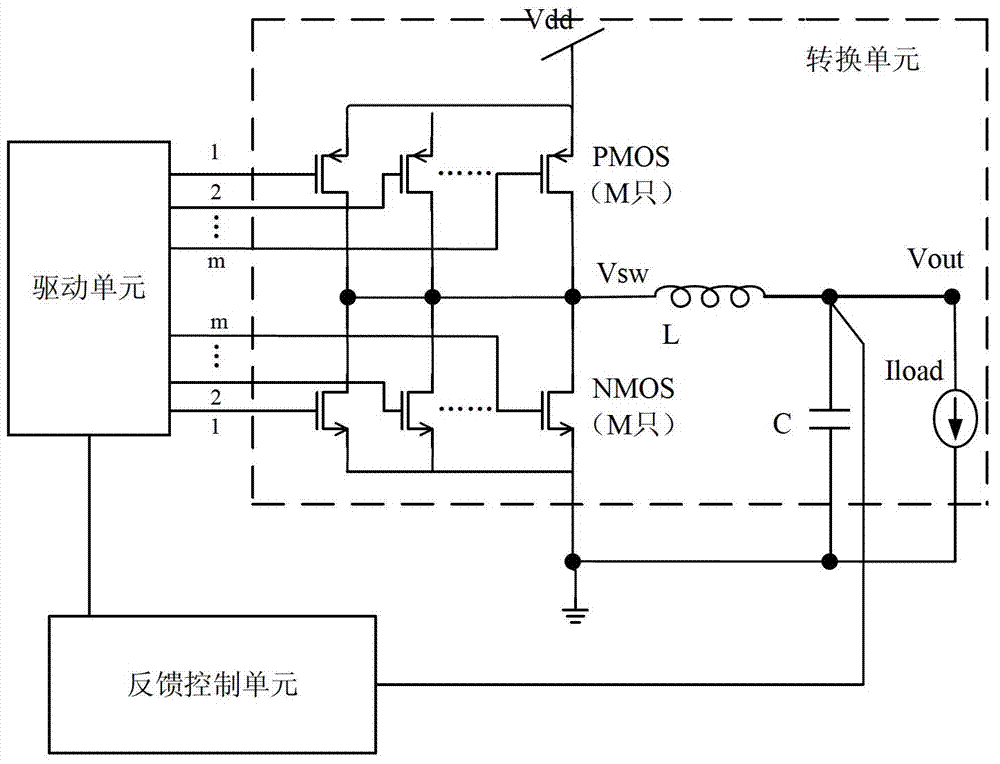

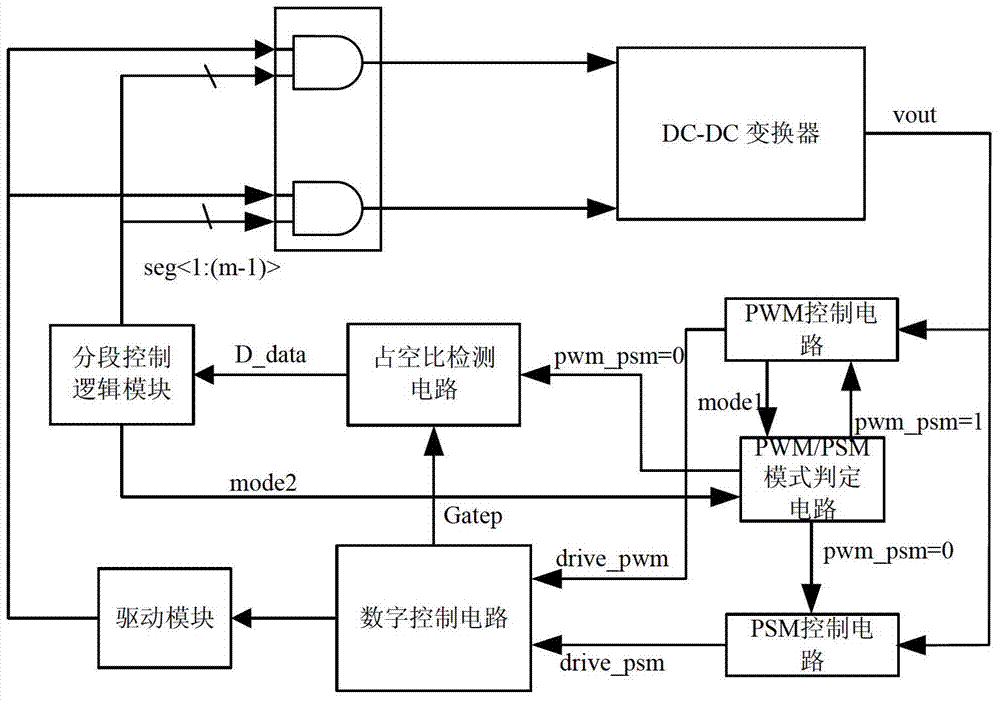

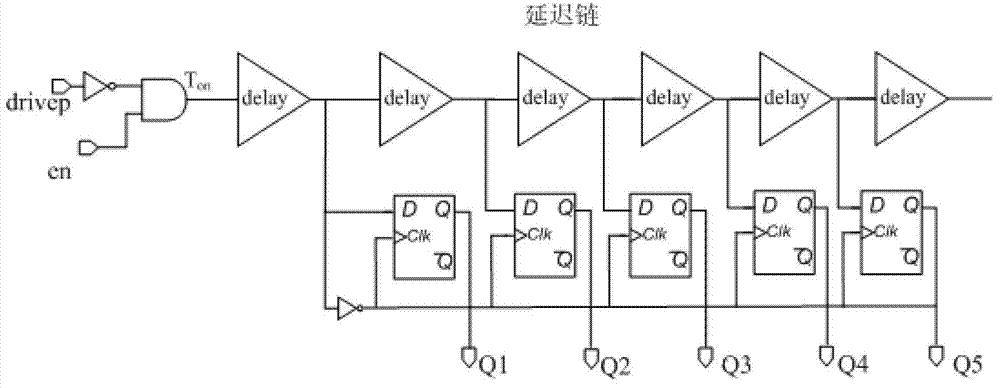

[0032] This example is in figure 1 36 PMOS power tubes and 36 NMOS power tubes are used, and the 36 power tubes are divided into 6 sections of PMOS power tubes and 6 sections of NMOS power tubes, and 1 section of PMOS power tubes is composed of 6 PMOS power tubes. Tubes are connected in parallel. Similarly, 1 segment of NMOS power tubes is composed of 6 NMOS tubes in parallel. The significance is to split the switching circuit composed of 36 PMOS power tubes and 36 NMOS power tubes into 6 sub-unit segments that are independently controlled. , in order to achieve the purpose of flexible control, the specific circuit structure is as figure 2 As shown, wherein the feedback control unit also includes a PWM control circuit, a PSM control circuit, a digital control circuit, a PWM / PSM mode determination circuit and a duty cycle detection circuit, and the drive unit includes a segmented control logic module and a drive module, so The input terminals of the PWM control circuit and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com