Method of correcting initial position of rotor of permanent magnet synchronous motor

A technology of rotor initial position and permanent magnet synchronous motor, which is applied in the direction of control of generator, motor generator control, control of electromechanical transmission, etc. It can solve the problems of rotor inability to move, large range of rotor movement, unsafety, etc., and achieve enhanced flexibility performance and immunity, improved position detection accuracy, adjustable frequency and amplitude

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

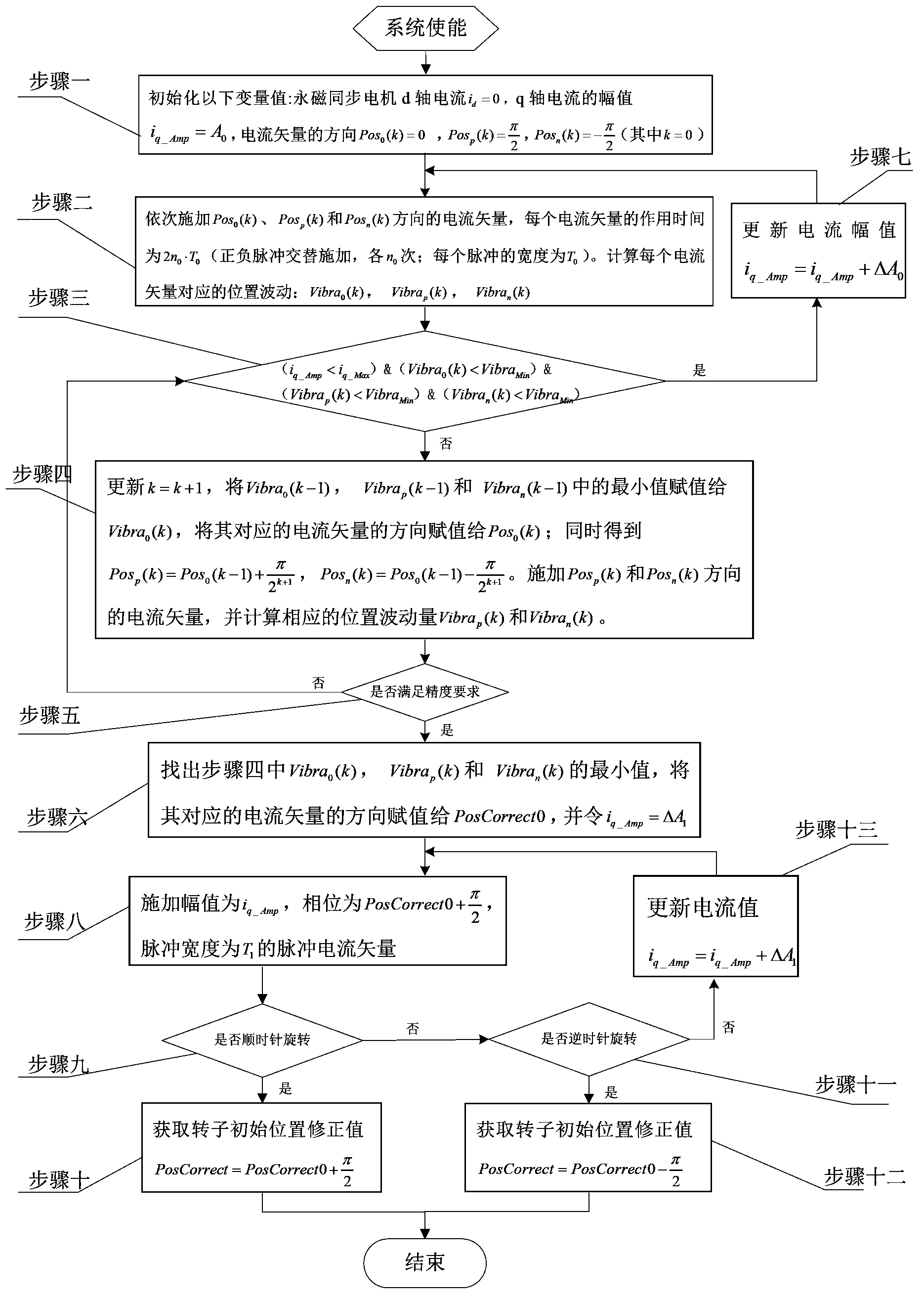

[0031] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

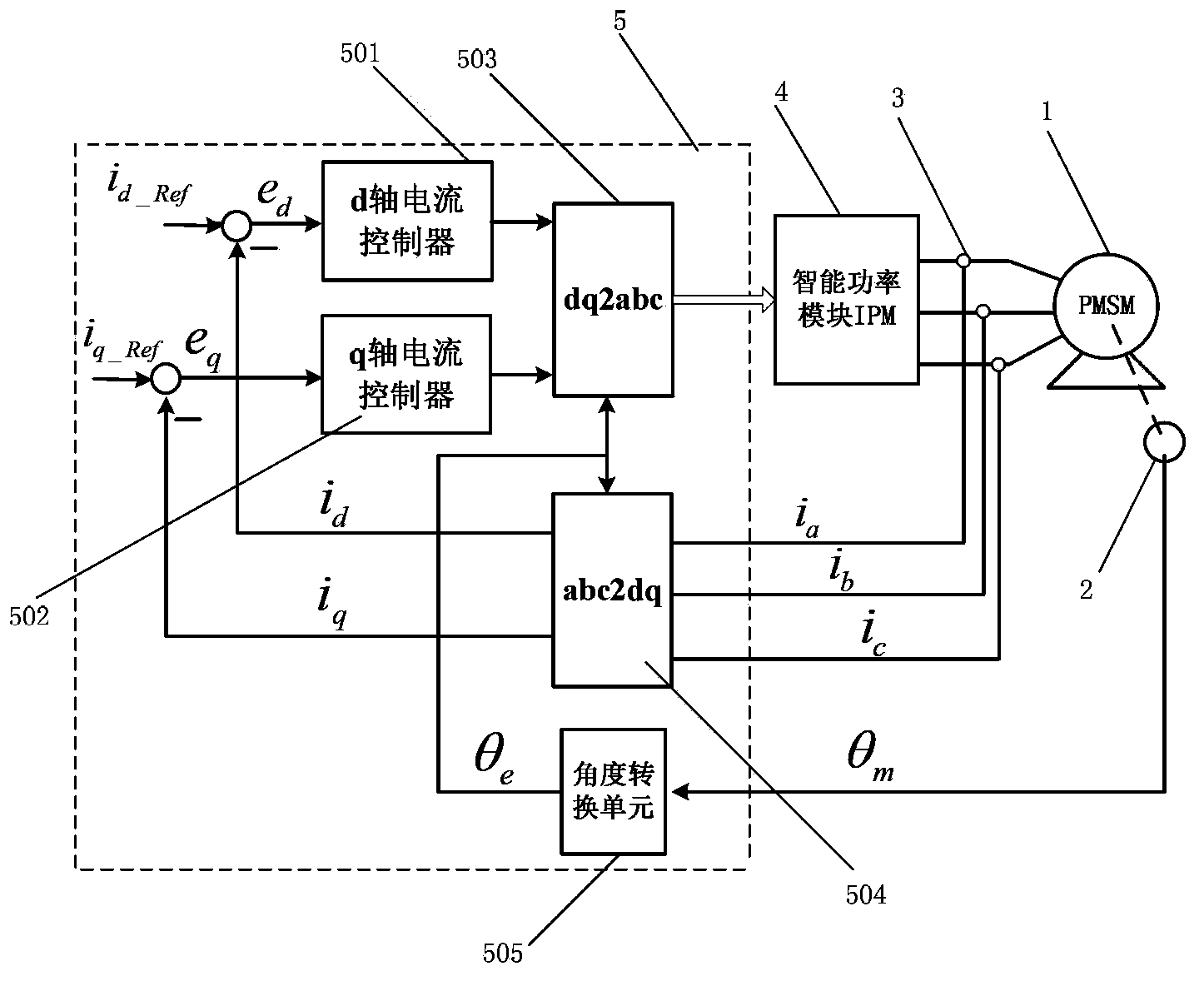

[0032] combine first figure 2 Introduce the structure of the permanent magnet synchronous motor drive control system: it mainly includes permanent magnet synchronous motor PMSM1, position sensor 2, current sensor 3, intelligent power module IPM4, and digital controller 5. The digital controller 5 mainly includes a d-axis current controller 501 , a q-axis current controller 502 , a dq2abc transformation module 503 , an abc2dq transformation module 504 , and an angle conversion unit 505 .

[0033] Among them, the rated torque of the permanent magnet synchronous motor PMSM1 is 460Nm, the rated current is 20A, and the number of pole pairs is 12; the position sensor 2 can be an absolute position sensor or a relative position ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com