Pressure vessel sealing

A technology of pressure vessels and pressure chambers, applied in pressure vessels, presses, presses for material forming, etc., can solve time-consuming and complicated problems, achieve small volume, reduce residual stress, and facilitate transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The invention is mainly described with reference to a few examples. However, a person skilled in the art will readily appreciate that other embodiments than those disclosed are equally possible within the scope of the invention as defined by the appended claims.

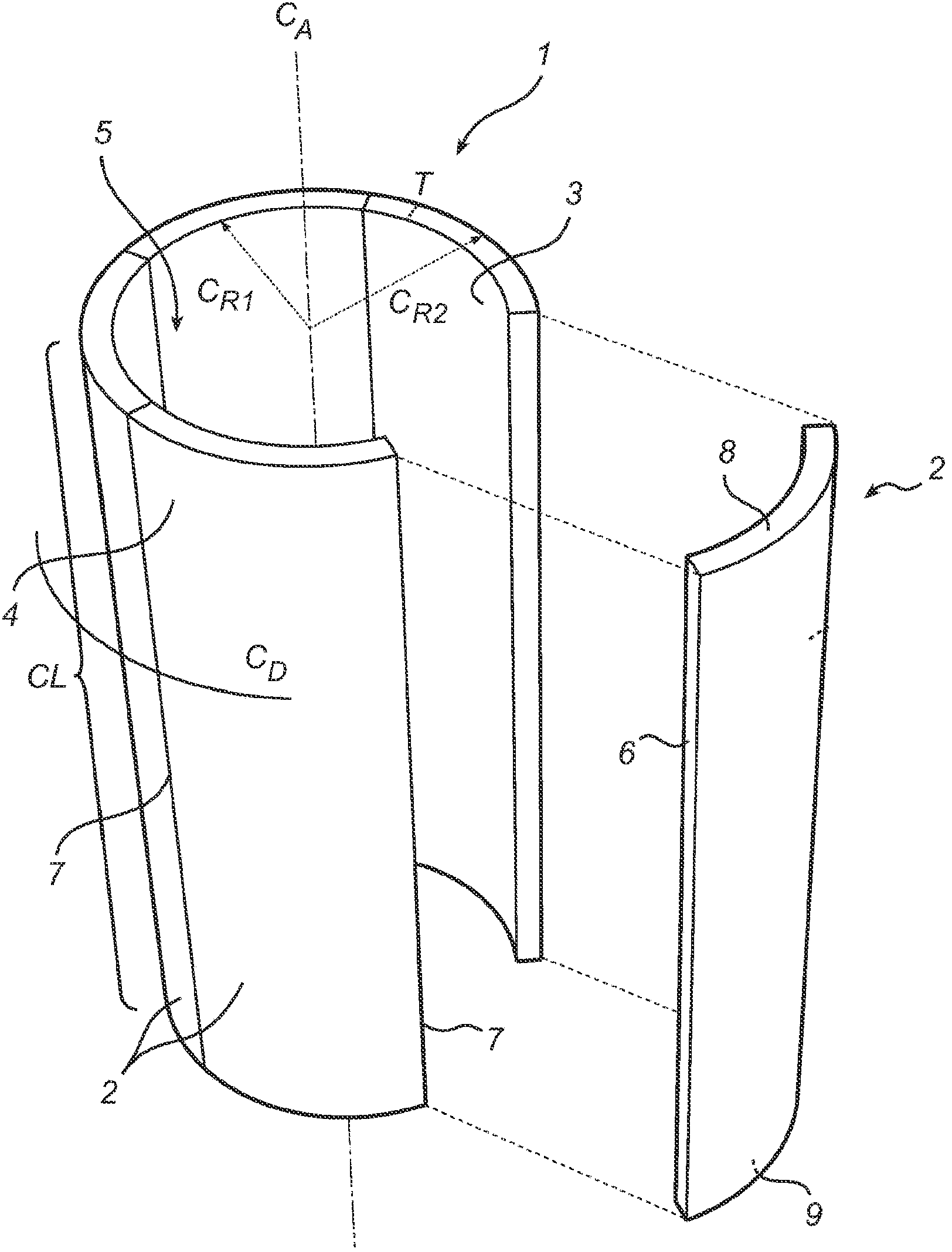

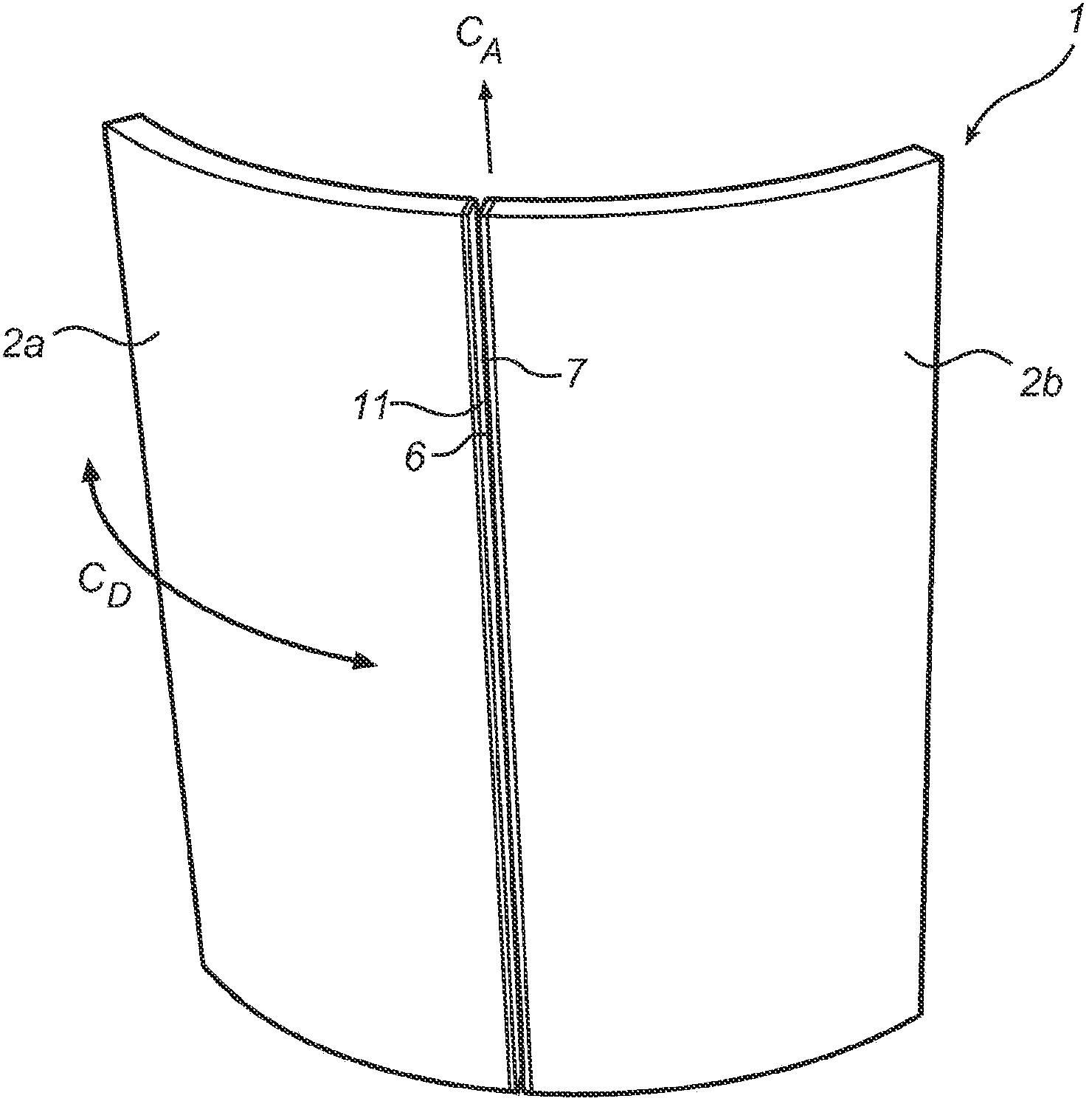

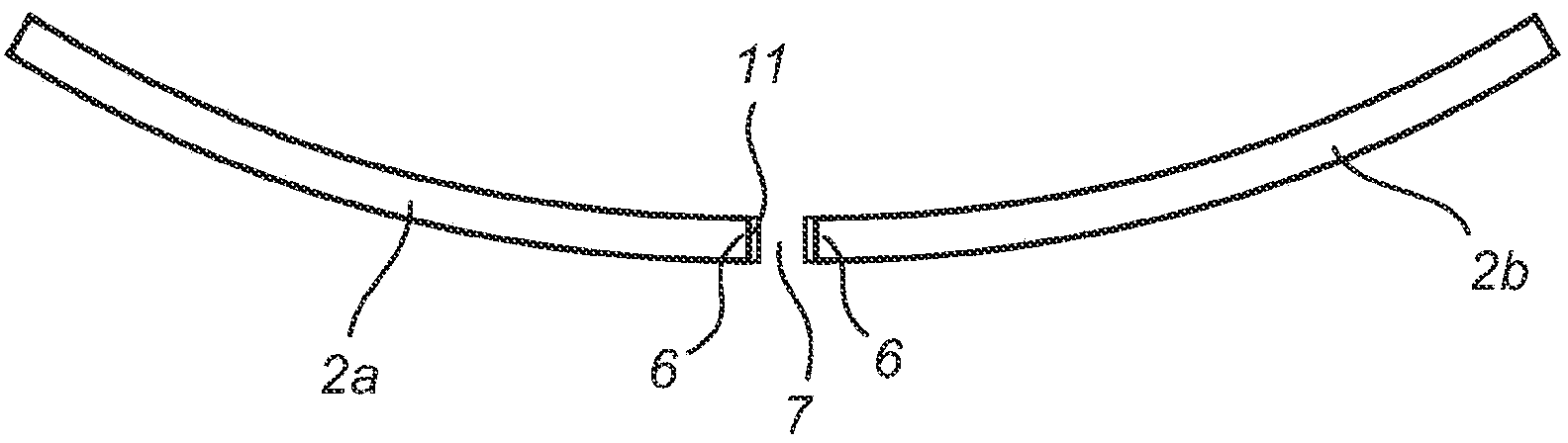

[0047] refer to figure 1 , schematically shows an illustration of a cylindrical body 1 according to an embodiment of the present invention. The cylinder main body 1 includes five cylinder segments 2, each of which has the shape of a substantially rectangular flat plate. The length of the cylinder section 2 is parallel to the cylinder axis C A extension, where the length of the cylinder segment 2 defines C L is the length of cylinder body 1. The width of the cylinder section 2 is along the circumferential direction C D Slightly arched, so that the cylinder segment 2 is arranged for D connected to each other to form a cylindrical body 1 .

[0048] Although in figure 1 The cylinder body 1 described in inc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| bulk modulus | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com