Boom for construction machine

A technology of construction machinery and jib, applied in the direction of mechanically driven excavators/dredgers, etc., can solve problems such as large time and labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

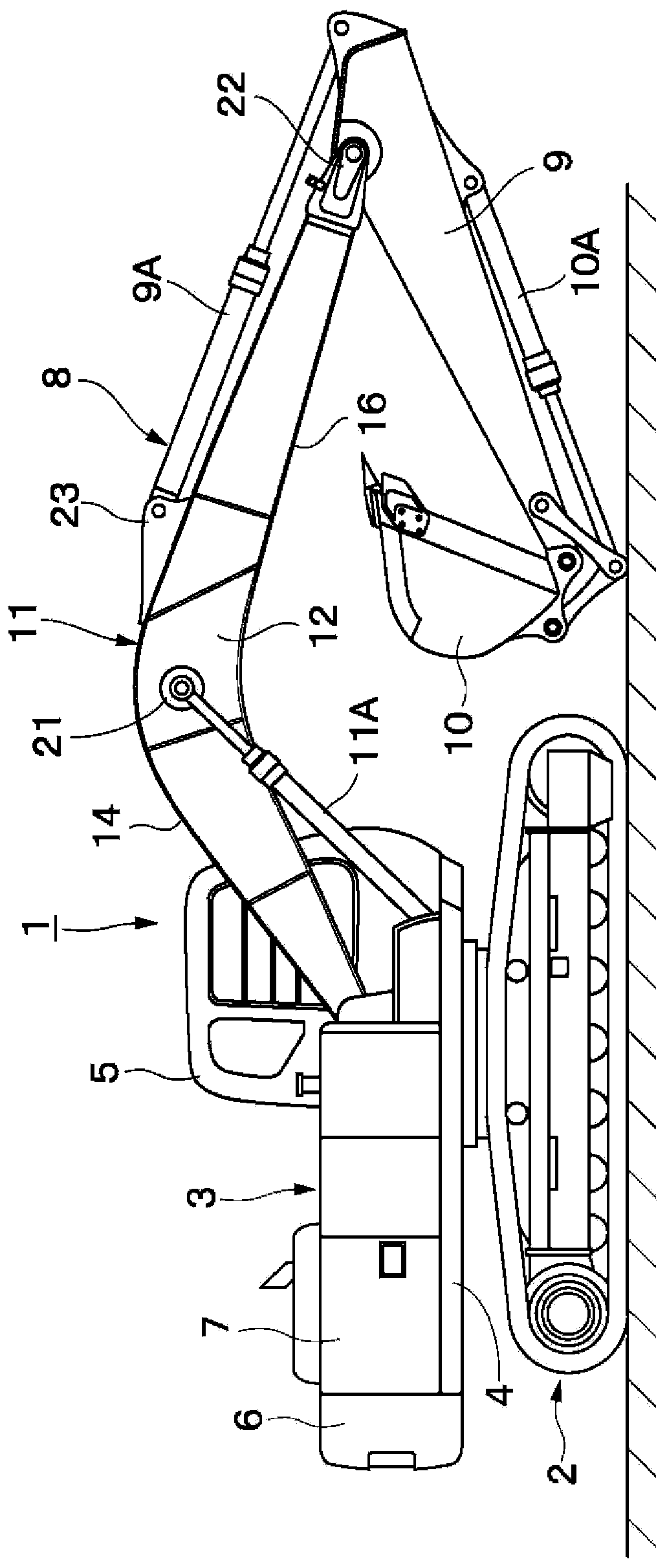

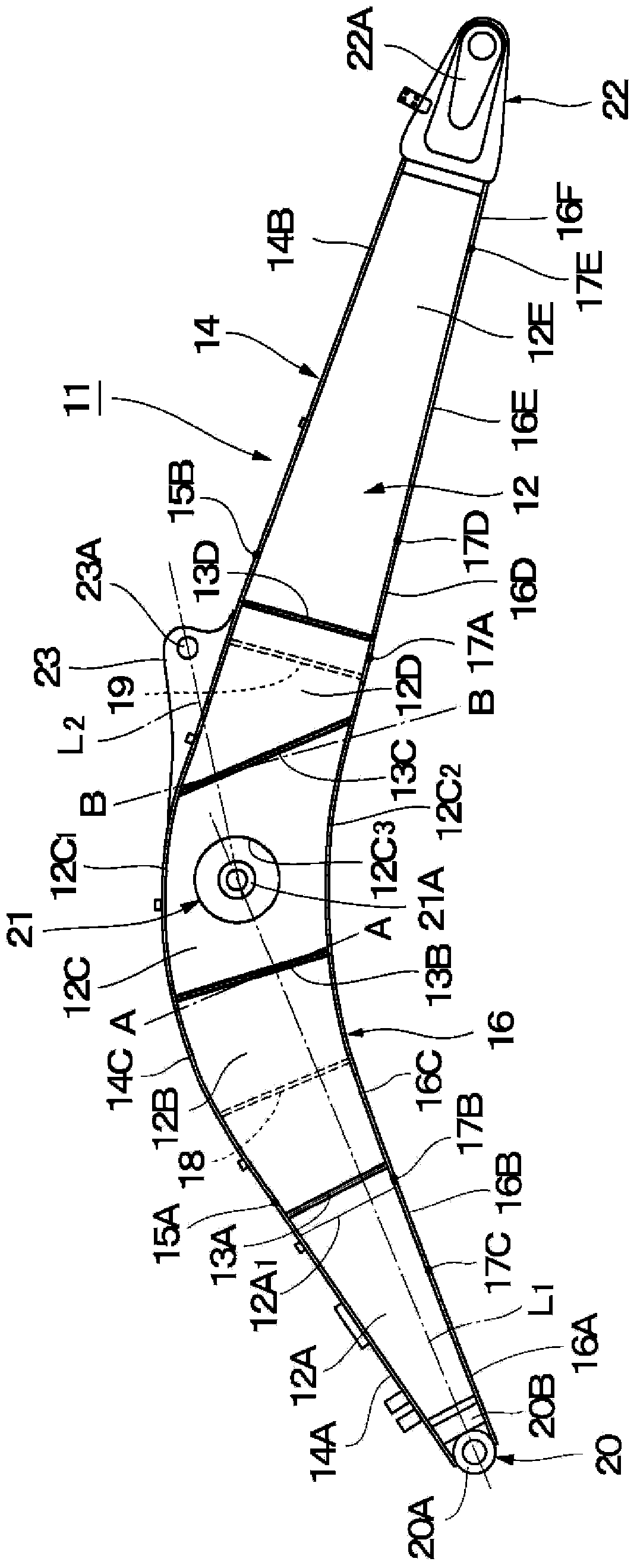

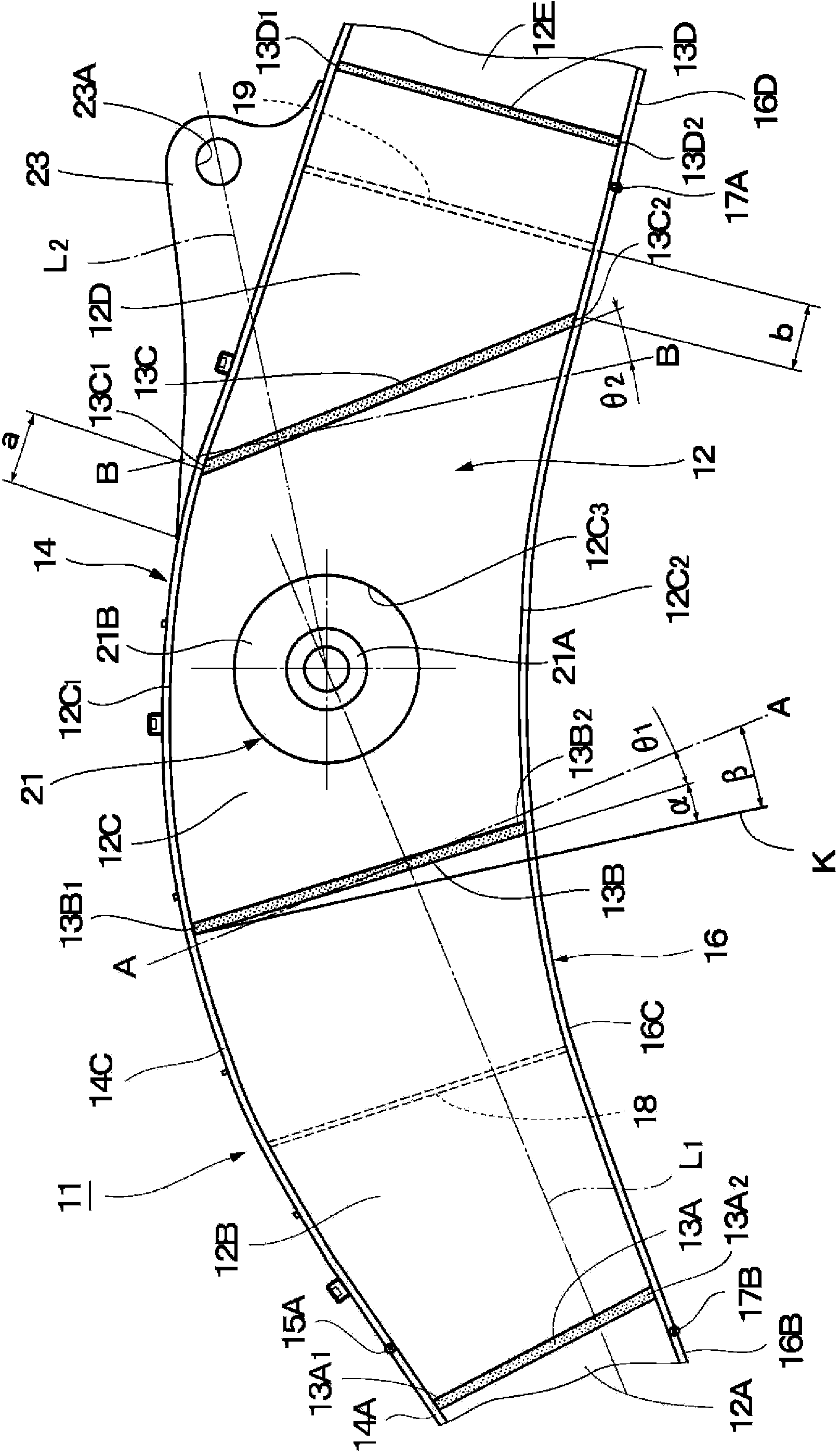

[0032] Hereinafter, the construction machine boom according to the embodiment of the present invention will be described in detail with reference to the drawings, taking the case of being applied to a boom of a hydraulic excavator as an example.

[0033] here, Figure 1 to Figure 9 A boom of a hydraulic excavator according to a first embodiment of the present invention is shown.

[0034] In the figure, symbol 1 is a hydraulic excavator as an engineering machine, and the hydraulic excavator 1 roughly includes: figure 1 A crawler-type undercarriage 2 capable of propelling itself as shown; an upper revolving unit 3 rotatably mounted on the undercarriage 2 ; and a working device 8 described later. The upper revolving body 3 of the hydraulic excavator 1 together with the undercarriage 2 constitutes a vehicle body of the construction machine. The upper revolving body 3 is composed of a revolving frame 4 , a cab 5 , a counterweight 6 , a cabin cover 7 and the like which will be des...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com