Modularized landscape plant wall system capable of being fast constructed and disassembled

A modular and plant wall technology, applied in the field of landscape plant wall systems, can solve the problems of limited erection height, difficult maintenance methods, high demand for the number of workers and specialization, and achieve the elimination of maintenance worries, low artificial technology requirements, and easy construction. with the effect of dismantling quickly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Below by embodiment, in conjunction with accompanying drawing, technical scheme of the present invention is described further in detail:

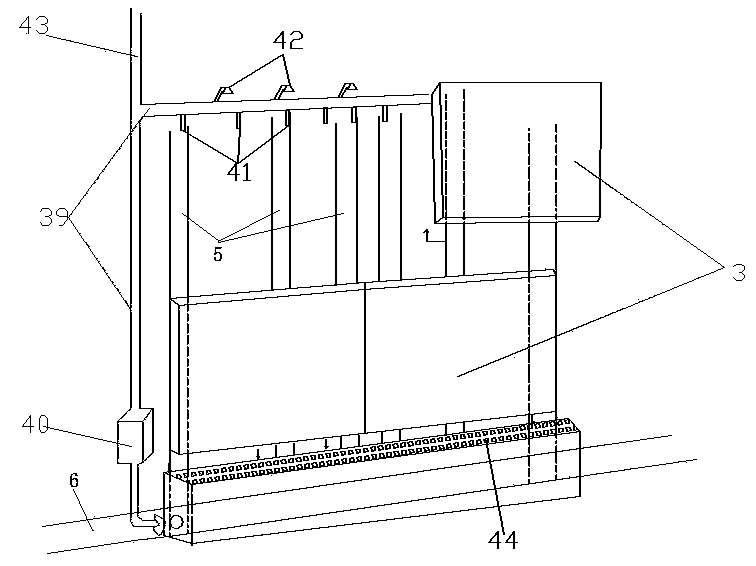

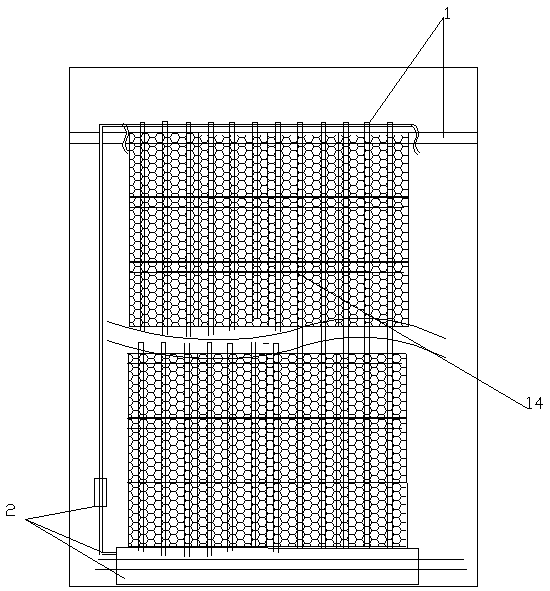

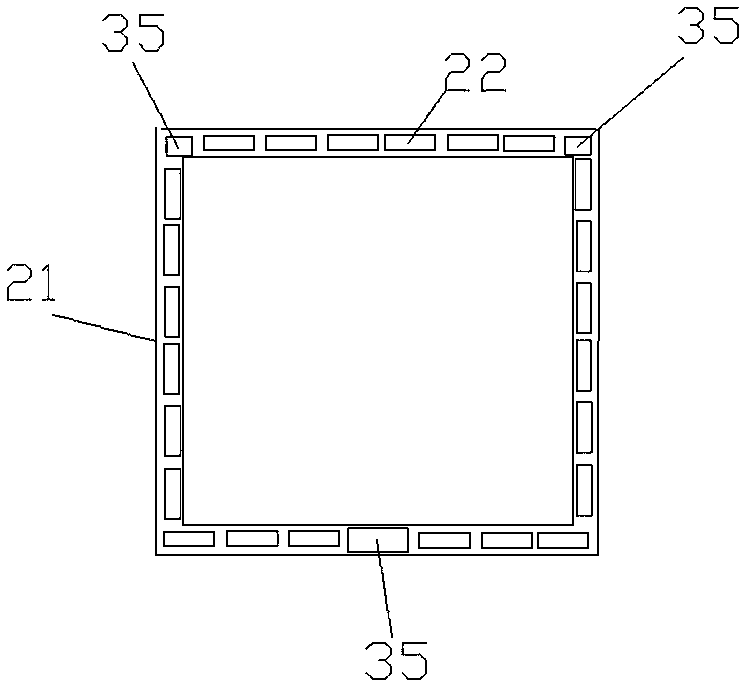

[0034] Such as Figure 1-9As shown, a modular landscape plant wall system that can be quickly constructed and disassembled includes a bracket 1, an irrigation system 2 and a modular planting block 3. After the foundation is leveled, a support is set on the facade 4 along the building wall, slope, etc., and the support is composed of an I-shaped metal beam 5 and an I-shaped metal beam fixing frame 6. The metal beam fixing frame and the I-shaped metal beam fixing frame Set at the foundation and the top of the plant wall, the flying wings 11 at the top and bottom of the I-shaped metal beam and the mid-belly are provided with screw holes 7, and the I-shaped metal beams are in groups of three. If the overall height of the plant wall is 5-30 meters, the left and right sides of the I-shaped metal beam group are steel I-shaped metal beams, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com