Colored fair-faced concrete anti-crack protection system and its construction method

A technology of fair-faced concrete and construction methods, which is applied to the processing of building components, structural elements, and building materials, and can solve problems such as increased thickness and cracks on the surface of colored fair-faced concrete, so as to avoid cracking, improve binding effects and surface smoothness, light weight effect

Active Publication Date: 2019-10-01

BEIJING NO 3 CONSTR ENG

View PDF5 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The invention provides a colored fair-faced concrete anti-cracking protection system and a construction method thereof, which solve the problem of increasing the thickness of the colored fair-faced concrete reinforcing bar protective layer and producing cracks on the colored fair-faced concrete surface through the mutual cooperation of the positioning device for the protective layer of concrete reinforcement and the anti-cracking steel bars

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Login to View More

Abstract

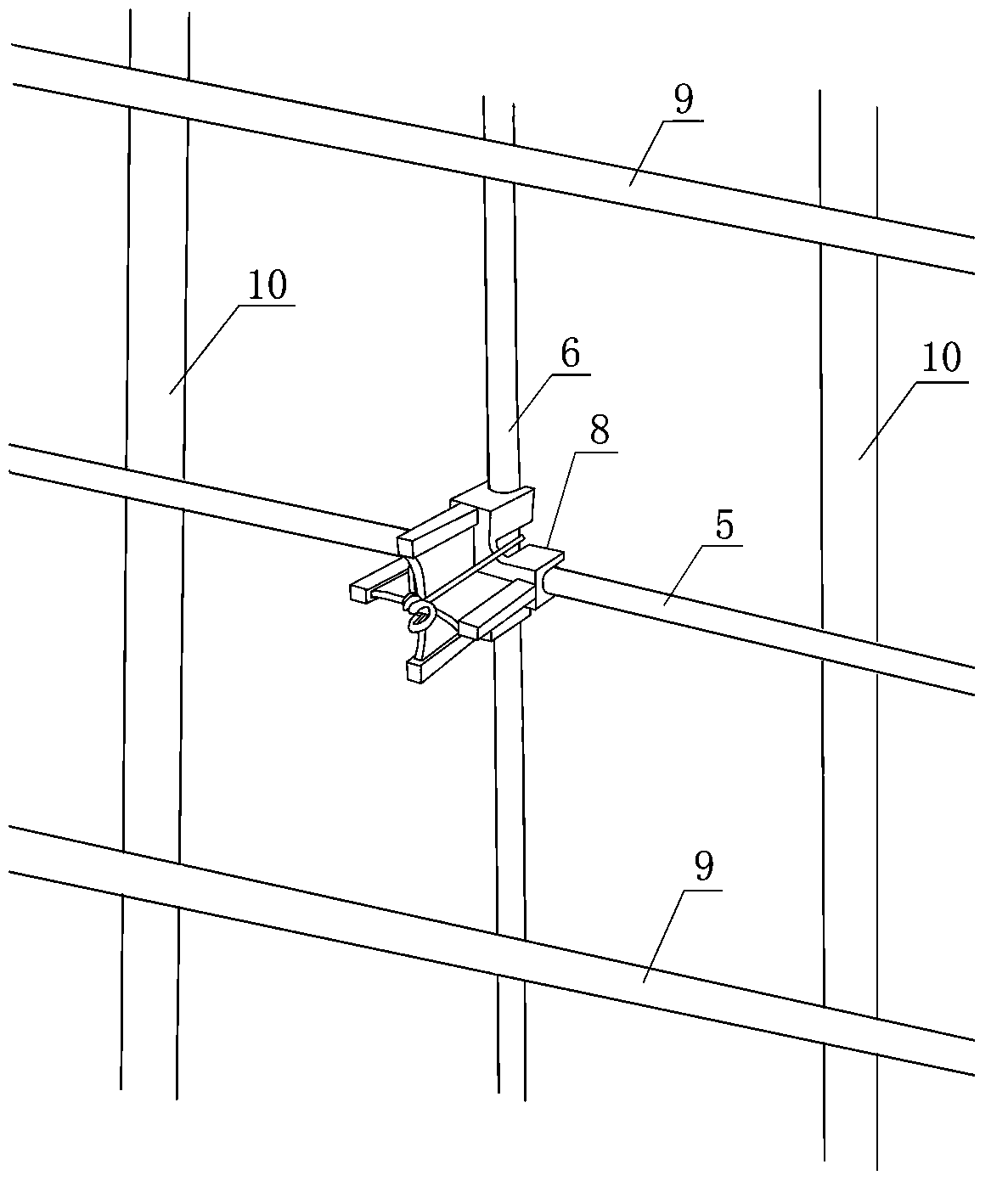

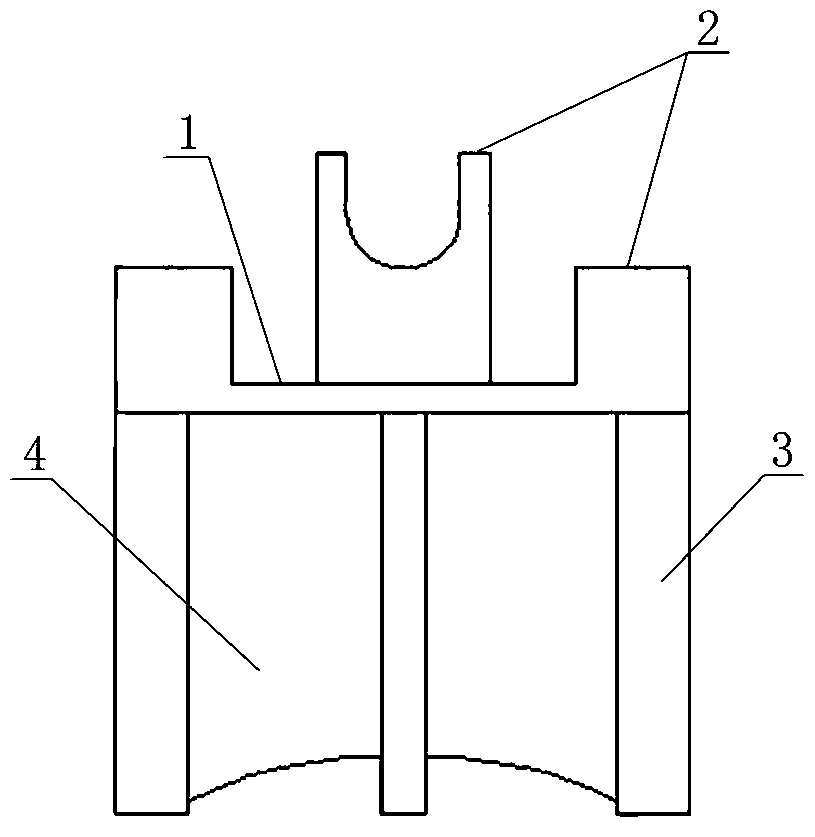

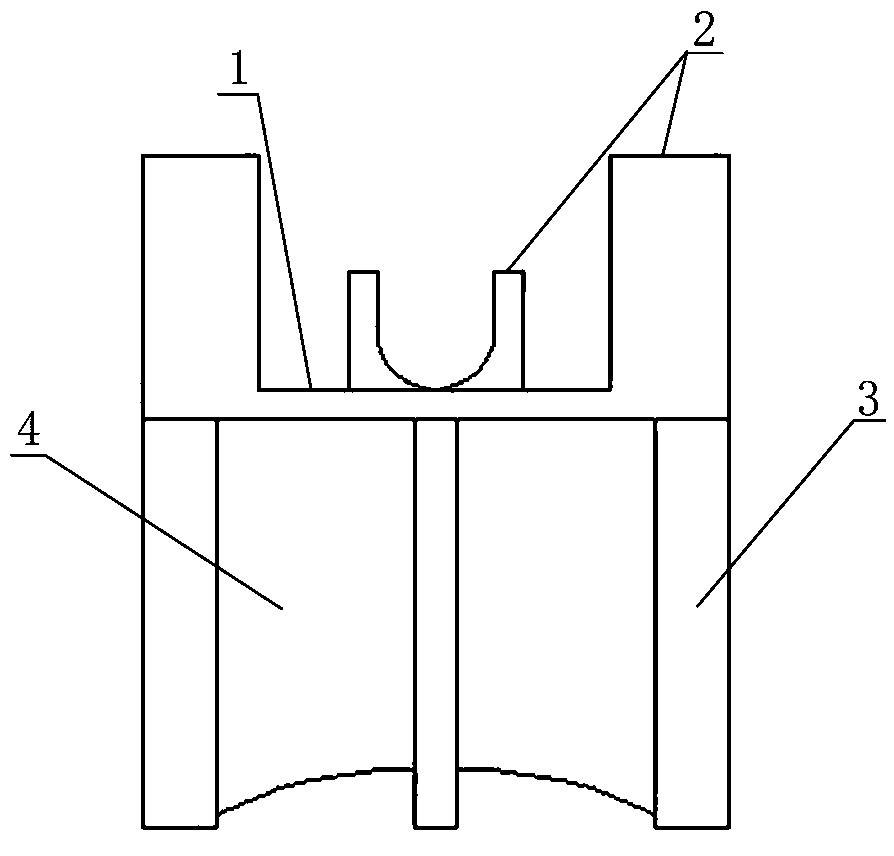

The invention discloses a colored finish concrete anti-crack protection system and a construction method thereof. Horizontal anti-crack reinforcements and vertical anti-crack reinforcements are bound on outer stress reinforcements of colored finish concrete, concrete reinforcement protection layer positioning devices are fixed to crosses of the vertical anti-crack reinforcements and the horizontal anti-crack reinforcements at intervals, the horizontal anti-crack reinforcements are clamped into two low clamp slots, the vertical anti-crack reinforcements are clamped into two high clamp slots, the concrete reinforcement protection layer positioning devices are firmly bound with the vertical anti-crack reinforcements and the horizontal anti-crack reinforcements by binding wires, and ends of the binding wires are placed in recesses in the lower portions of the positioning devices. Based on reinforcing bars of originally designed wall reinforcements, the anti-crack reinforcements are additionally arranged in horizontal and vertical directions, the anti-crack effect of the colored finish concrete is greatly improved, and the problem of mutual contradiction between reinforcement protection layer increase and colored finish concrete crack prevention is effectively solved.

Description

technical field The invention relates to an anti-crack protection system of colored fair-faced concrete and a construction method thereof. Background technique In GB50010-2010 "Code for Design of Concrete Structures", the thickness of the ordinary concrete protective layer in the first-class environment category is generally 15mm for wall panels and 20mm for beams and columns, but the colored fair-faced concrete walls are directly exposed to the air due to the cancellation of the finish layer In the process, the carbonation of concrete is bound to be accelerated, which will cause the concrete to lose its protective effect on the steel bar prematurely, causing problems such as bluntness of the steel bar, corrosion, and cracking of the protective layer along the bar. Therefore, the thickness of the reinforced protective layer of colored fair-faced concrete is larger than that of ordinary concrete, generally 30mm, which has stricter requirements on the thickness of the reinforc...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): E04C5/20E04G21/00

Inventor 崔建滨王云磊王俊林王宪武李东蓝斌艾云忠闻兴业

Owner BEIJING NO 3 CONSTR ENG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com