Planting frame

A technology for planting racks and planting pots, applied in the field of planting racks, can solve the problems of bulky, cumbersome installation, and rough appearance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

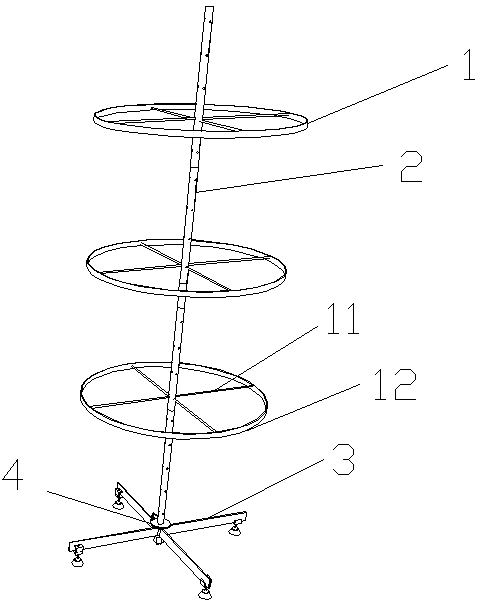

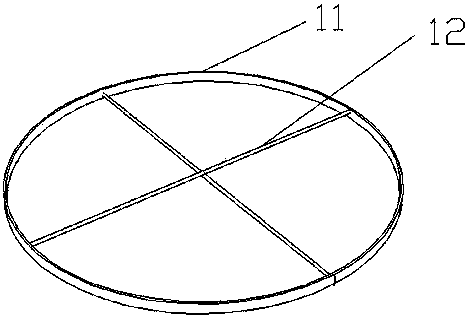

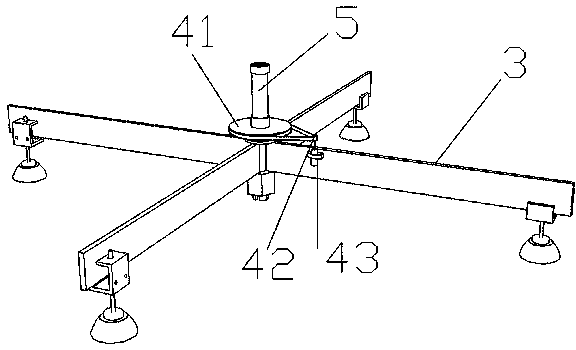

[0017] refer to figure 1 , 2 , 3, 4, a planting frame, including a mounting base 3, a drive assembly 4, a control assembly, and a central column 3, the mounting base 3 is snapped together by two steel plates crossed, and is divided into four pieces at the intersection with the lower end The sleeve 5 is clamped, and the upper end of the sleeve 5 is inserted inside the center column 3; the control assembly is installed on the mounting seat 3, and the driving assembly 4 is composed of a set of belt drive wheels. Including a driving wheel 42, a driven wheel 41, a belt and a motor 43, the driven wheel 41 is sleeved on the sleeve 5, and can drive the center column 3 to rotate, the motor 43 is fixed on the On the steel plate, the motor 43 drives the driving wheel 42; the drive assembly 4 drives the center column 3 to rotate around its own axis under the control of the control member, and the bottom end of the center column 3 is connected to the mounting seat 3. The planting frame a...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap