A kind of preparation method of total diterpene extract of quasi-fragrance-deficient tea vegetables

A technology for imitating tea vegetables lacking in fragrance and total diterpenes, which is applied in the field of medicine to achieve great economic and social benefits, simple method and good quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

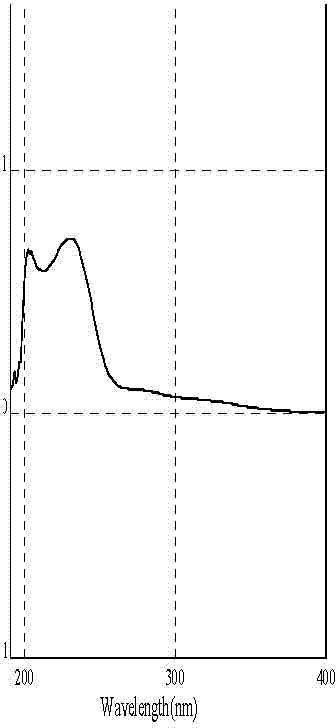

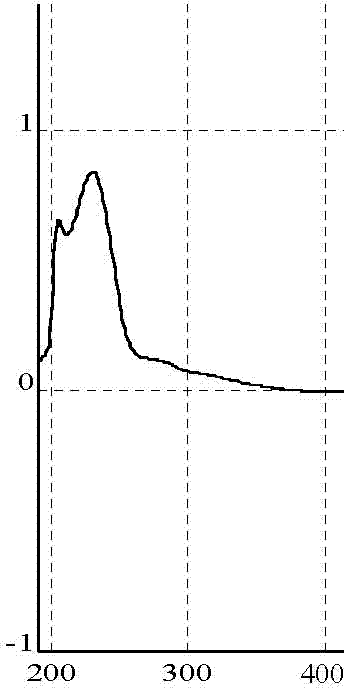

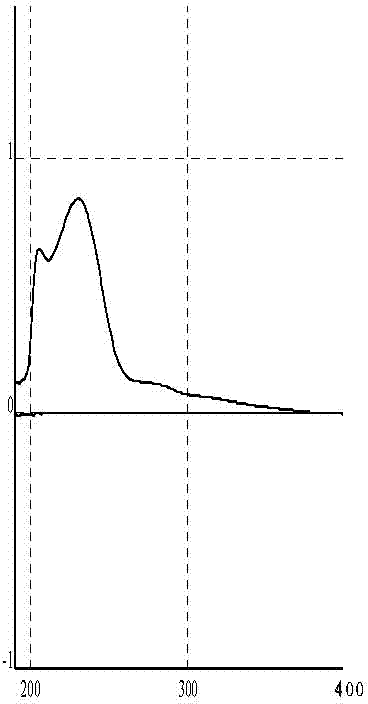

Image

Examples

Embodiment 1

[0020] In concrete implementation, the present invention is realized by the following steps:

[0021] (1) Preparation of the sample solution: crush 1kg of the dried medicinal materials to be lacking in fragrant tea, add water to decoct twice, each time for 1 hour, add 12L of water for the first time, add 8L of water to the medicinal residue for the second time, Combine the two water decoctions, filter, let stand and cool to room temperature, and obtain 10L of supernatant, which is the sample solution;

[0022] (2) Resin pretreatment: The method is to soak the D101 macroporous adsorption resin in ethanol with a volume concentration of 95% for 24 hours, then wet-pack the column, and dynamically clean the resin with ethanol with a volume concentration of 95%. 5 times the volume of the resin, washed with water until there is no alcohol smell, soaked in hydrochloric acid with a volume concentration of 5% for 6 hours, and dynamically cleaned the resin. The amount of hydrochloric aci...

Embodiment 2

[0026] The present invention is realized by the following steps:

[0027] (1) Preparation of the sample solution: crush 1kg of the dried medicinal materials to be lacking in fragrant tea, add water to decoct twice, each time for 1 hour, add 12L of water for the first time, add 8L of water to the medicinal residue for the second time, Combine the two water decoctions, filter, let stand and cool to room temperature, and obtain 10L of supernatant, which is the sample solution;

[0028] (2) Resin pretreatment: The method is to soak the HP20 macroporous adsorption resin with ethanol with a volume concentration of 95% for 24 hours, then wet-pack the column, and use ethanol with a volume concentration of 95% to dynamically clean the resin. The amount of ethanol added 5 times the volume of the resin, washed with water until there is no alcohol smell, soaked in hydrochloric acid with a volume concentration of 5% for 6 hours, and dynamically cleaned the resin. The amount of hydrochloric...

Embodiment 3

[0032] The present invention is realized by the following steps:

[0033] (1) Preparation of the sample solution: crush 1kg of the dried medicinal materials to be lacking in fragrant tea, add water to decoct twice, each time for 1 hour, add 12L of water for the first time, add 8L of water to the medicinal residue for the second time, Combine the two water decoctions, filter, let stand and cool to room temperature, and obtain 10L of supernatant, which is the sample solution;

[0034] (2) Resin pretreatment: The method is to soak the AB8 macroporous adsorption resin in ethanol with a volume concentration of 95% for 24 hours, then wet-pack the column, and use ethanol with a volume concentration of 95% to dynamically clean the resin. The amount of ethanol added 5 times the volume of the resin, washed with water until there is no alcohol smell, soaked in hydrochloric acid with a volume concentration of 5% for 6 hours, and dynamically cleaned the resin. The amount of hydrochloric ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com