Desulfurizing absorption tower and desulfurizing absorption method

A technology of desulfurization absorption tower and absorption tower, which is applied in the field of desulfurization absorption tower and desulfurization absorption, can solve the problems of low efficiency of desulfurization absorption tower, achieve the effect of reducing the amount of circulating spray, reducing maintenance time, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

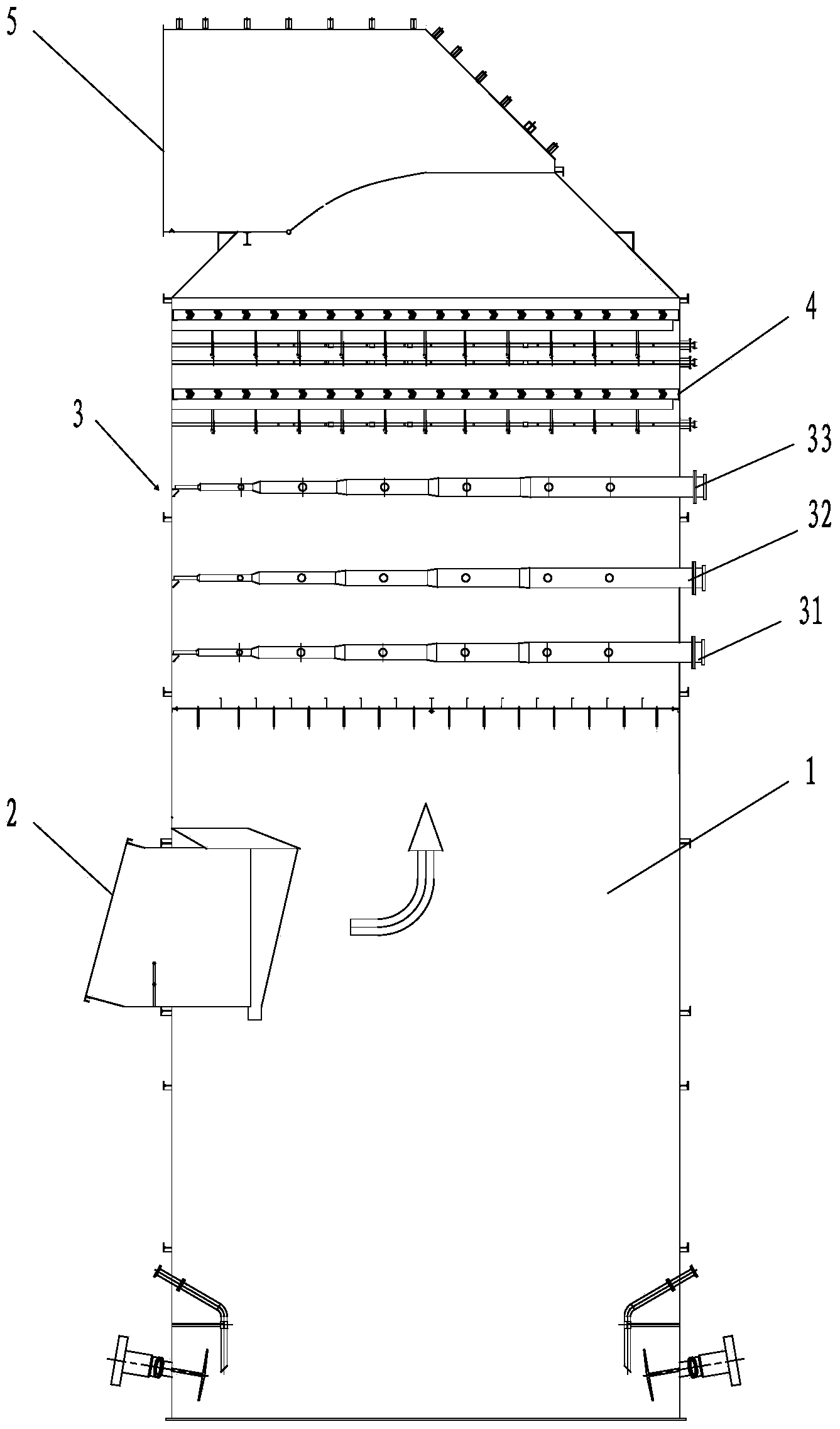

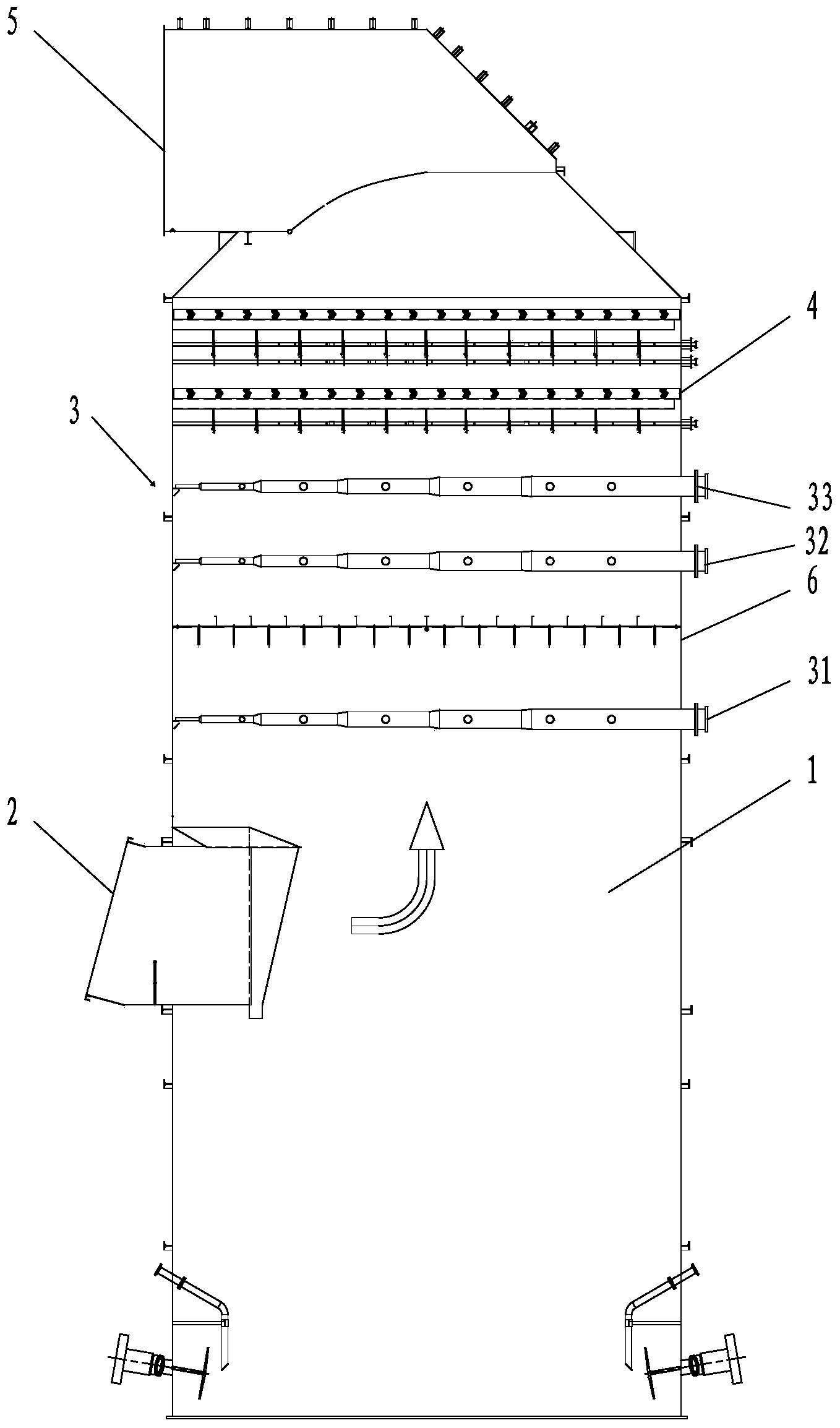

[0049] The implementation of the present invention will be described in detail below in conjunction with the accompanying drawings, but they do not constitute a limitation to the present invention, and are only examples. At the same time, the advantages of the present invention are made clearer and easier to understand by description, and the direction shown by the arrow in the figure is the gas flow direction.

[0050] Referring to the accompanying drawings, it can be seen that the desulfurization absorption tower includes a tower tube 1, and the inside of the tower tube 1 is sequentially installed with an absorption tower inlet 2, a spray layer 3, a demister 4, and an absorption tower outlet 5, and its characteristics in:

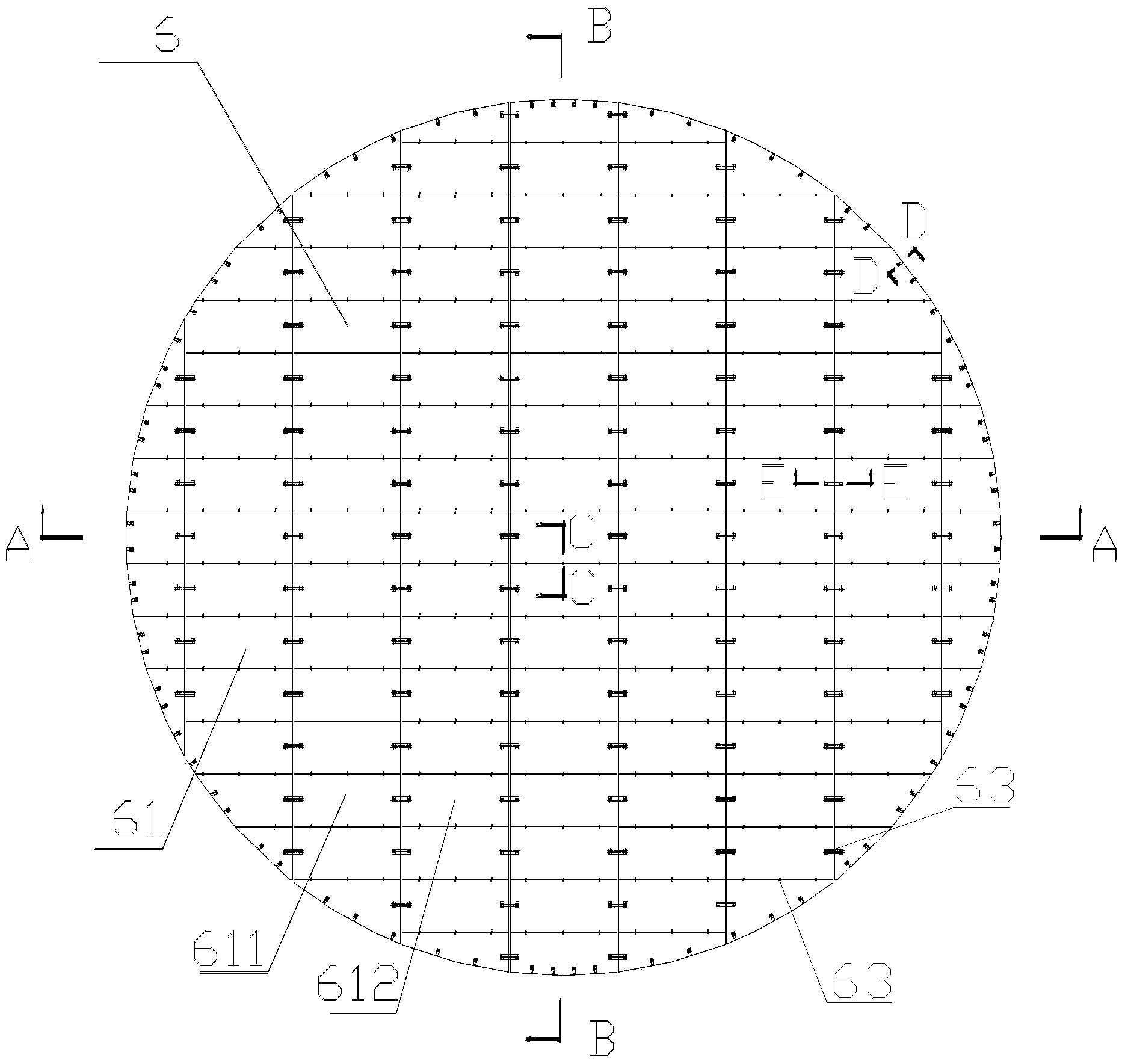

[0051] A porous distributor 6 is also installed inside the tower 1;

[0052] The spray layer 3 includes a first spray layer 31, a second spray layer 32 and a third spray layer 33 arranged at intervals from bottom to top, and the demister 4 is a two-stage...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com