Electric dust remover with moving anodes

An electrostatic precipitator and mobile anode technology, applied in the field of electrostatic precipitator, can solve the problems of weakening the advantages of the mobile anode electrostatic precipitator, increasing the cost and difficulty of transformation, and reducing the length of the effective electric field, so as to shorten the transformation period, improve the dust removal efficiency, The effect of shortening the length of the electric field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

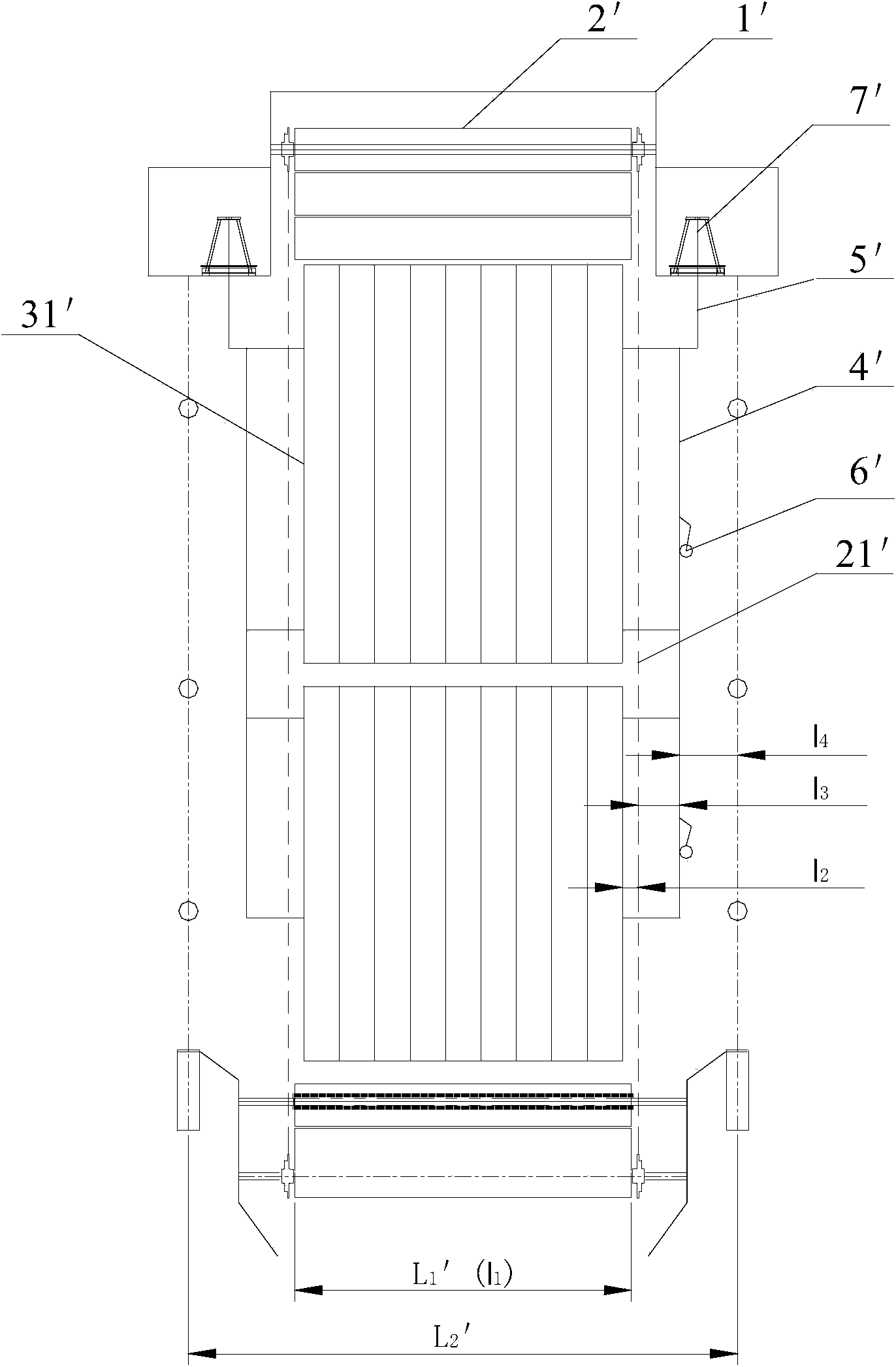

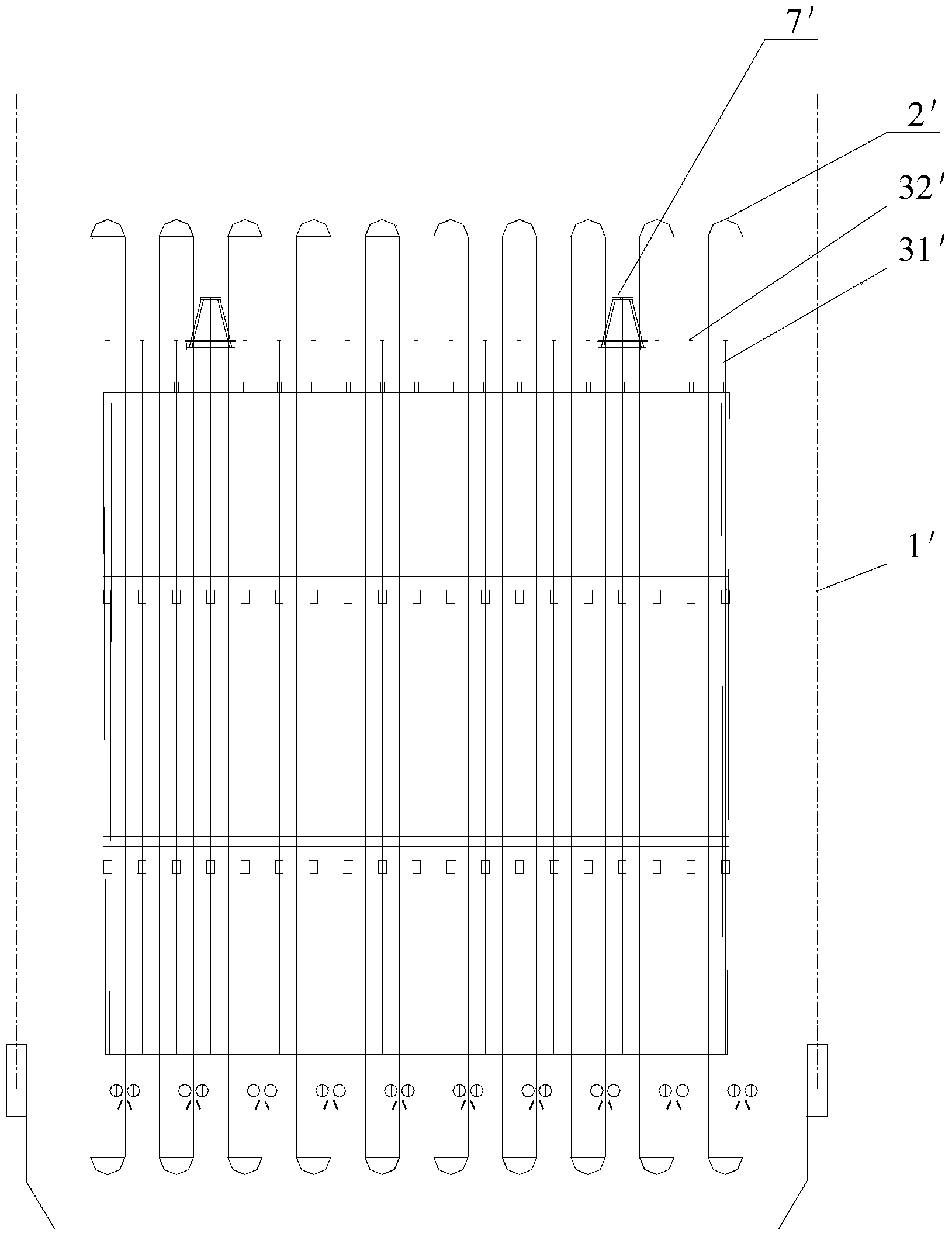

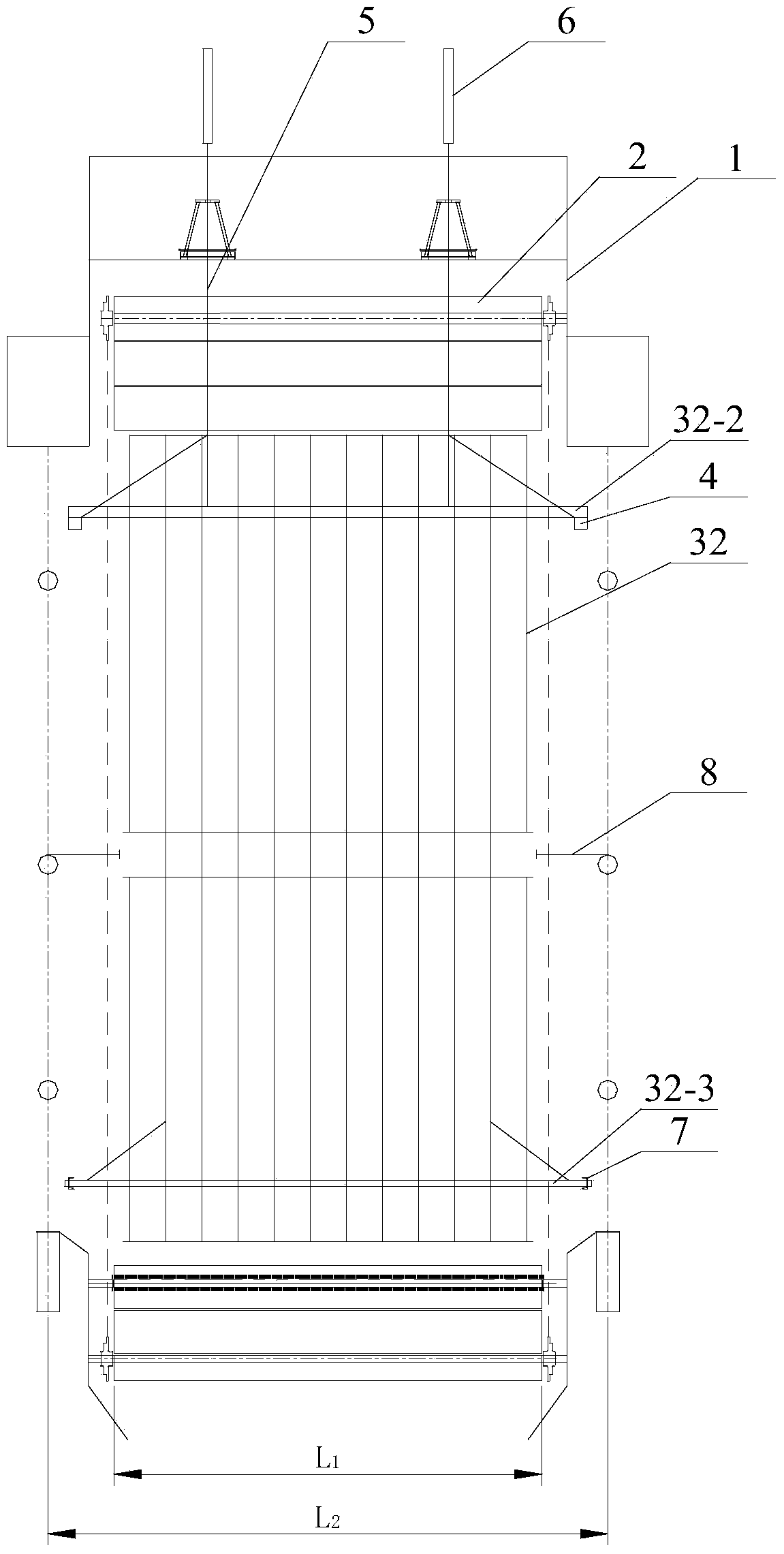

[0041]The core of the present invention is to provide a mobile anode electrostatic precipitator, by setting the suspension rod for suspending the integral structure formed by the first dust collection cathode and the second dust collection cathode on the second dust collection cathode, and making the The boom is located in the airflow channel formed by two adjacent dust collecting anodes, so that the actual electric field length of the mobile anode electrostatic precipitator is significantly reduced under the condition that the effective electric field length remains unchanged.

[0042] Without loss of generality, the following describes the specific implementation of the mobile anode electrostatic precipitator provided by the present invention in conjunction with the accompanying drawings.

[0043] See image 3 and Figure 4 ,in, image 3 It shows a schematic front view of a specific embodiment of the mobile anode electrostatic precipitator provided by the present invention...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap