Efficient processor for handling paint face sagging

A processing machine and sagging technology, applied in grinding machines, metal processing equipment, grinding/polishing equipment, etc., can solve the problems of affecting the appearance quality, difficult to guarantee the flatness of the paint film, low processing efficiency, etc., so as not to affect the appearance quality. , Good grinding stability and high processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

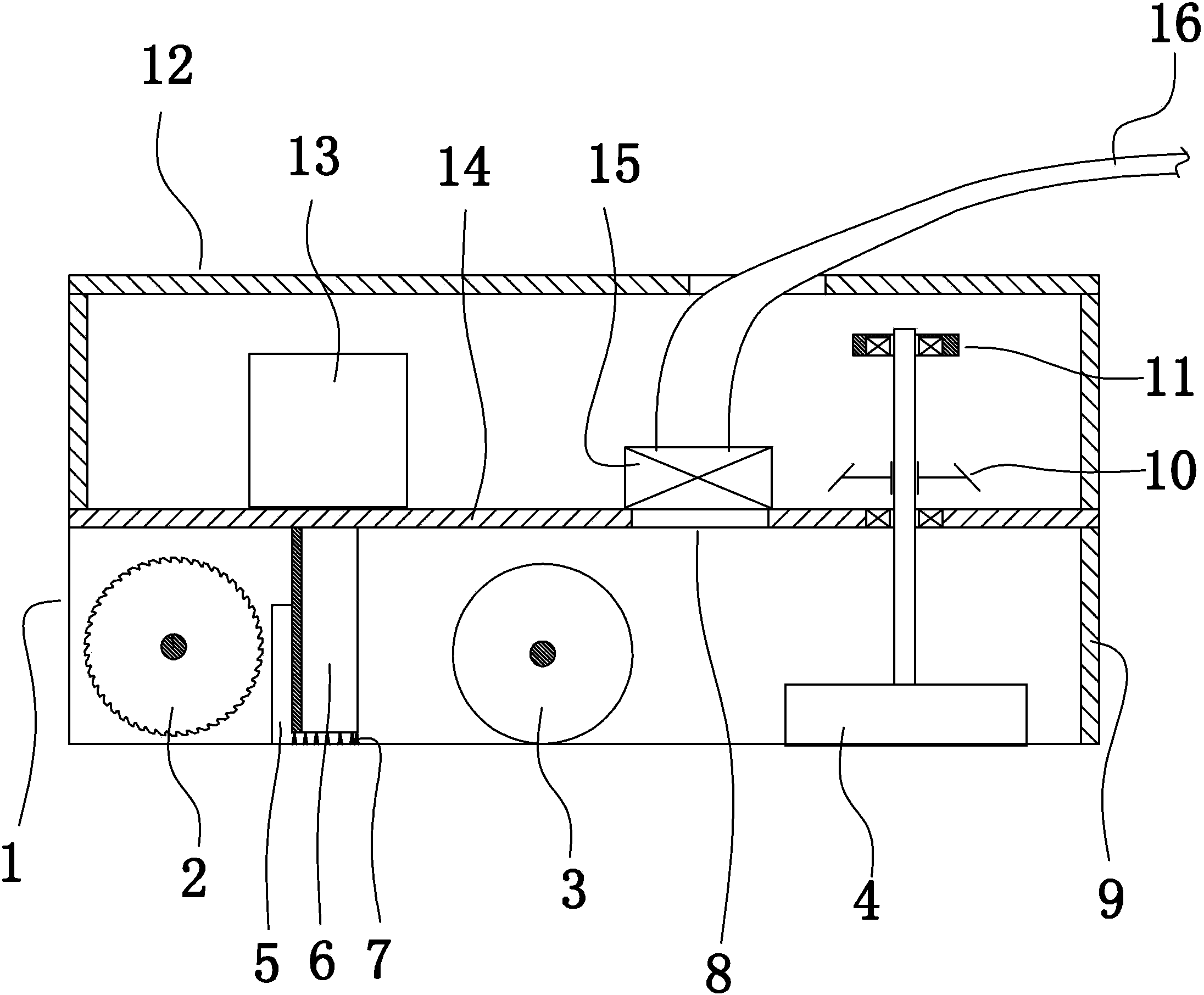

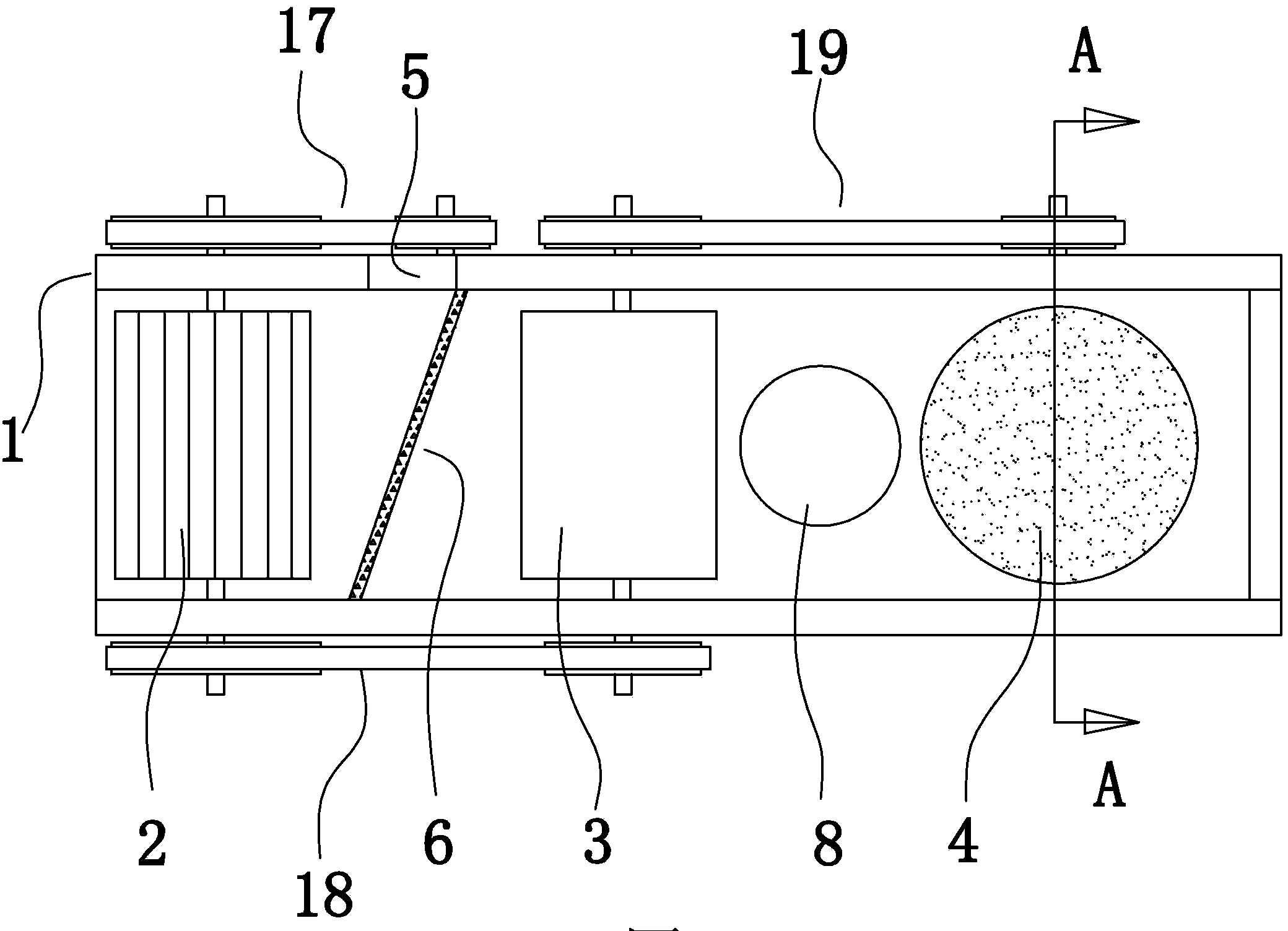

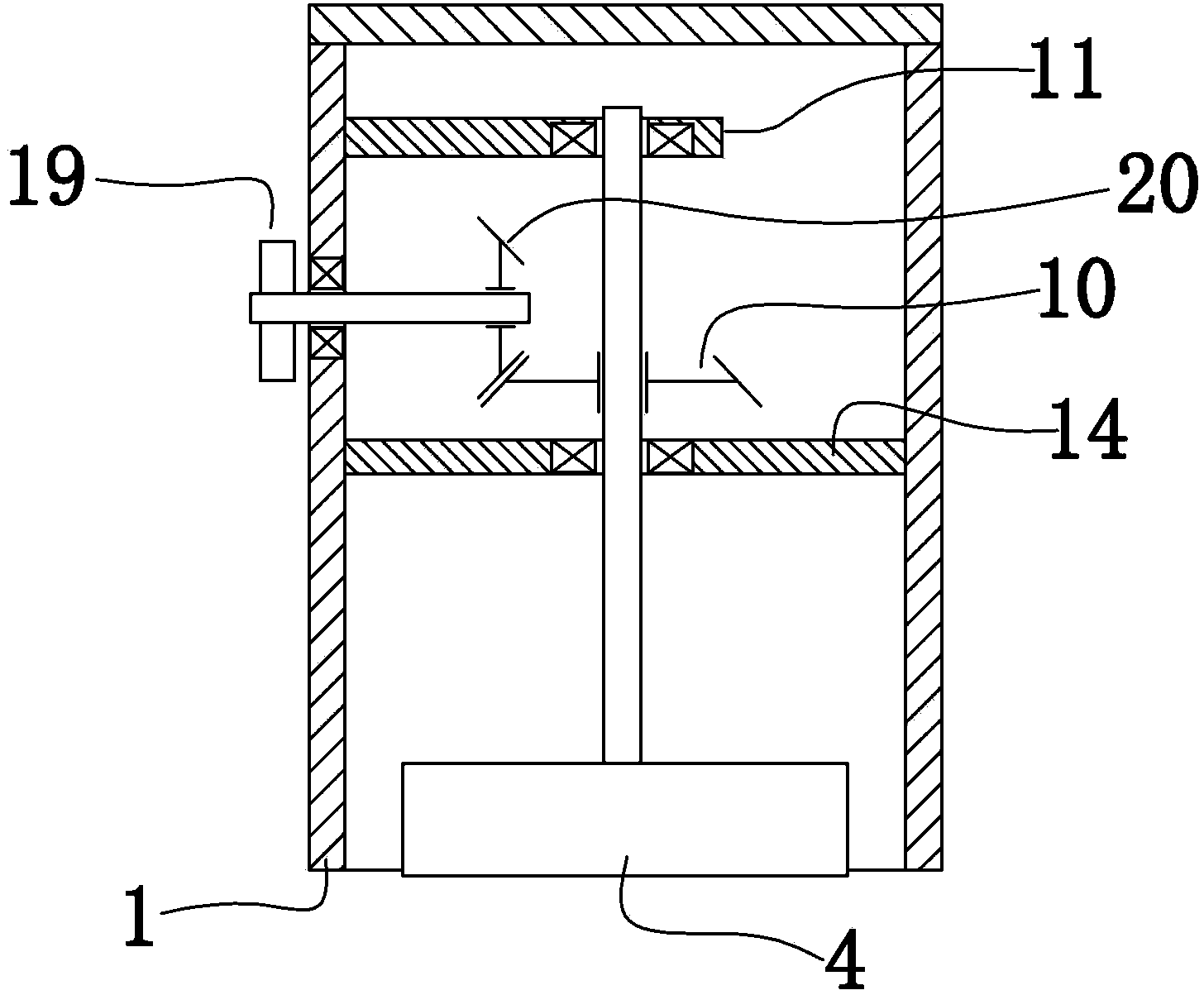

[0024] Embodiment 1: as figure 1 , Figure 4 As shown, a high-efficiency processor for paint surface sagging includes two supporting side plates 1 parallel to each other, a driving motor 13, a water tank 21 with an upper end opening and an exhaust hose 16. Between the two supporting side plates 1, a paint removing wheel 2, a grinding wheel 3 and a polishing wheel 4 are arranged sequentially from front to back. Between the two supporting side plates 1, an upper partition 14 is arranged above the paint removal wheel, the grinding wheel and the polishing wheel. Between the two supporting side plates, the rear partition 9 is located at the rear side of the polishing wheel 4 . Between the two supporting side plates 1, the paint removal wheel 2, the grinding wheel 3 and the polishing wheel 4 are located below and the front side of the paint removal wheel 2 is open. A cover 12 is also provided between the two supporting side plates 1 and above the upper partition 14 . The driving...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com