Double-end milling automatic multi-piece feeding mechanism

A feeding mechanism and double-end milling technology, applied in forming/shaping machines, special forming/shaping machines, wood processing appliances, etc., can solve the problems of no multi-piece feeding function, low work efficiency, and large material loss, etc. To achieve the effect of reducing the number of manual feeding, high work efficiency and increasing feeding volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

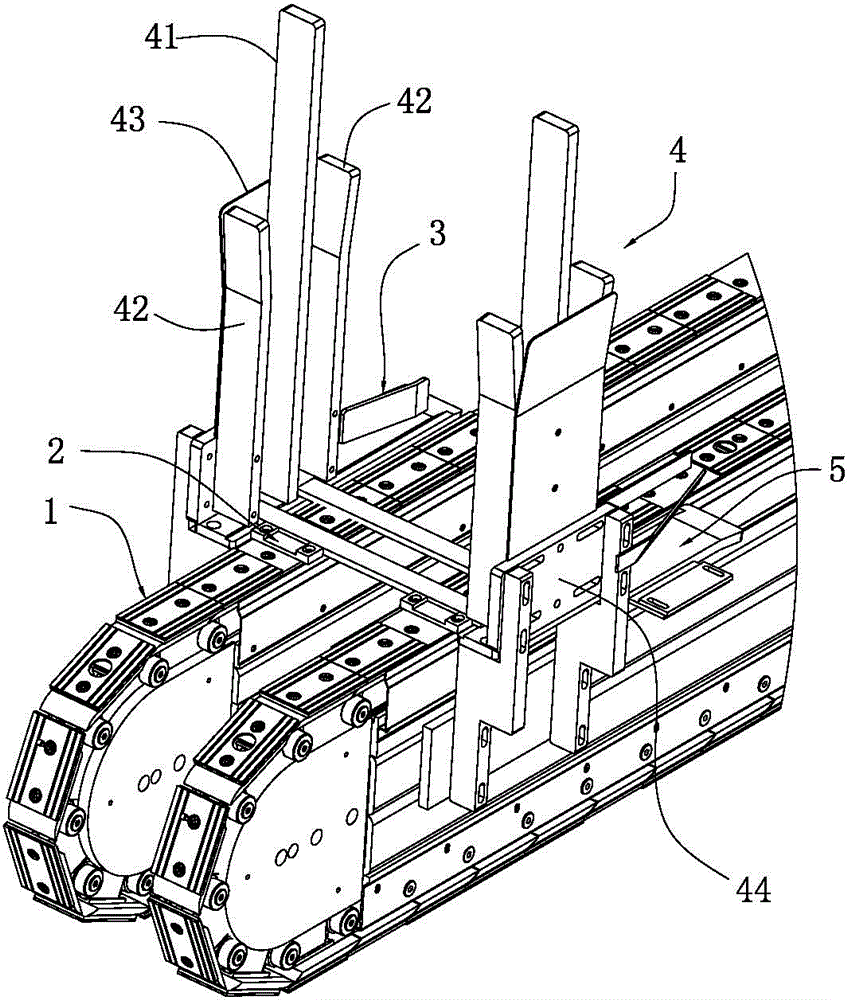

[0016] see figure 1 , a double-end milling automatic multi-piece feeding mechanism provided in this embodiment includes a feeding belt 1, a pushing block 2, a guide plate 3 and two multi-material bins 4, and each of the two multi-material bins 4 passes through a supporting plate 5 symmetrically arranged vertically on both sides of the feeding belt 1, the multi-stock bin 4 includes a middle spacer plate 41 and two wood width-adjusting plates 42 symmetrically arranged on both sides of the middle spacer plate 41, and the pushing block 2 It is arranged on the feeding belt 1, and the top surface level of the pushing block 2 is slightly higher than the top surface of the pallet 5, and the guide plate 3 is set on the feeding track position corresponding to the feeding belt 1. One side of multiple bunkers 4, so that the timber is neatly arranged on the feed belt 1.

[0017] The guide plate 3 is vertically arranged on the supporting plate 5, and the vertical surface at one end of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com