A helicopter rotor system capable of active shimmy

A helicopter rotor and active pendulum technology, applied in the field of helicopter rotor system, can solve the problems of limited blade adaptability and inability to realize large-scale shimmy motion, reduce forward resistance and backward stall tendency, and reduce fatigue load , Improve the effect of flying speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

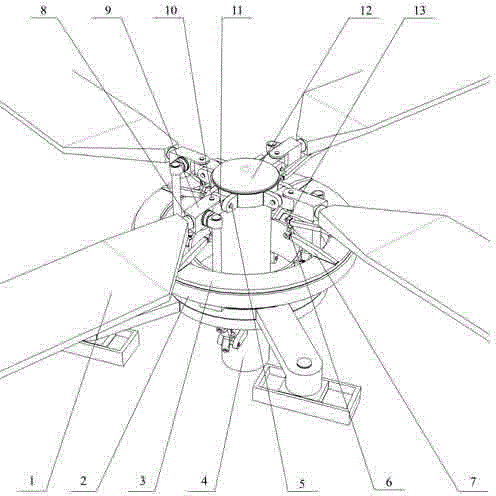

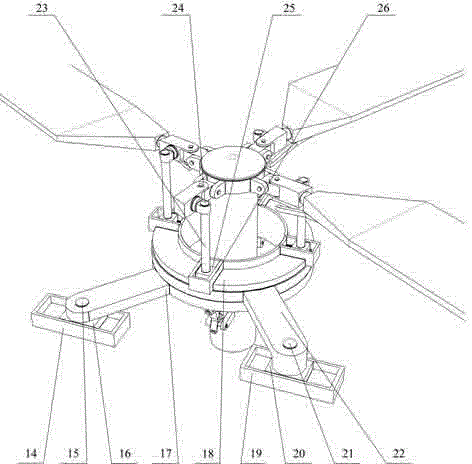

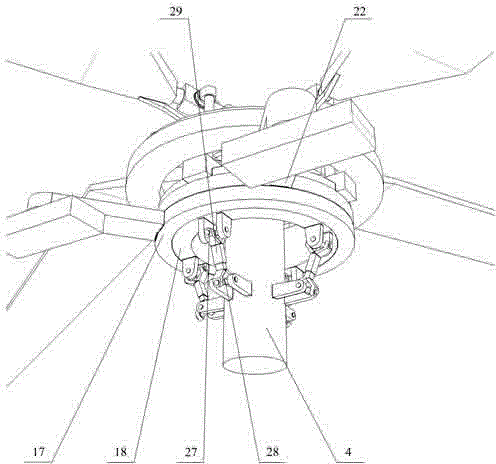

[0020] Please refer to Figure 1 to Figure 3 As shown, the active shimmy helicopter rotor system of the present invention includes a shimmy control mechanism, a universal joint link mechanism, a two-degree-of-freedom plane parallel restraint mechanism and an automatic tilter.

[0021] Please refer to figure 1 As shown, the automatic tilter includes a fixed ring 2, which can tilt in any direction and can also perform vertical displacement movement. A moving ring 3 is arranged on the fixed ring 2, and four moving ring connecting rods arranged in the center are arranged on it. 7. The inner end of the moving ring connecting rod 7 is hinged with a variable pitch rod 6, and the pitch variable rod 6 is connected to the connecting rod of the blade 1 through a pitch variable control hinge 13.

[0022] The propeller hub 12 is arranged on the top of the main shaft 4, and the propeller hub 12 is hinged with a swing hinge connector 11 through the swing hinge 5, and the swing hinge connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com