Three-dimensional electrode pattern manufacturing method

A technology of three-dimensional electrode and manufacturing method, which is applied in the field of micro-mechanical technology, can solve the problems of increasing difficulty of the process, and achieve the effect of simple process of process and high precision of graphic production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 2

[0068] In the second embodiment, in the step of etching the patterned mask layer 2 to obtain a three-dimensional electrode pattern, the etching solution used for etching the patterned mask layer 2 cannot corrode the protective film metal layer 6 . In the step of removing the protective film metal layer 6 , the etching solution used to corrode the protective film metal layer 6 cannot corrode the patterned mask layer 2 .

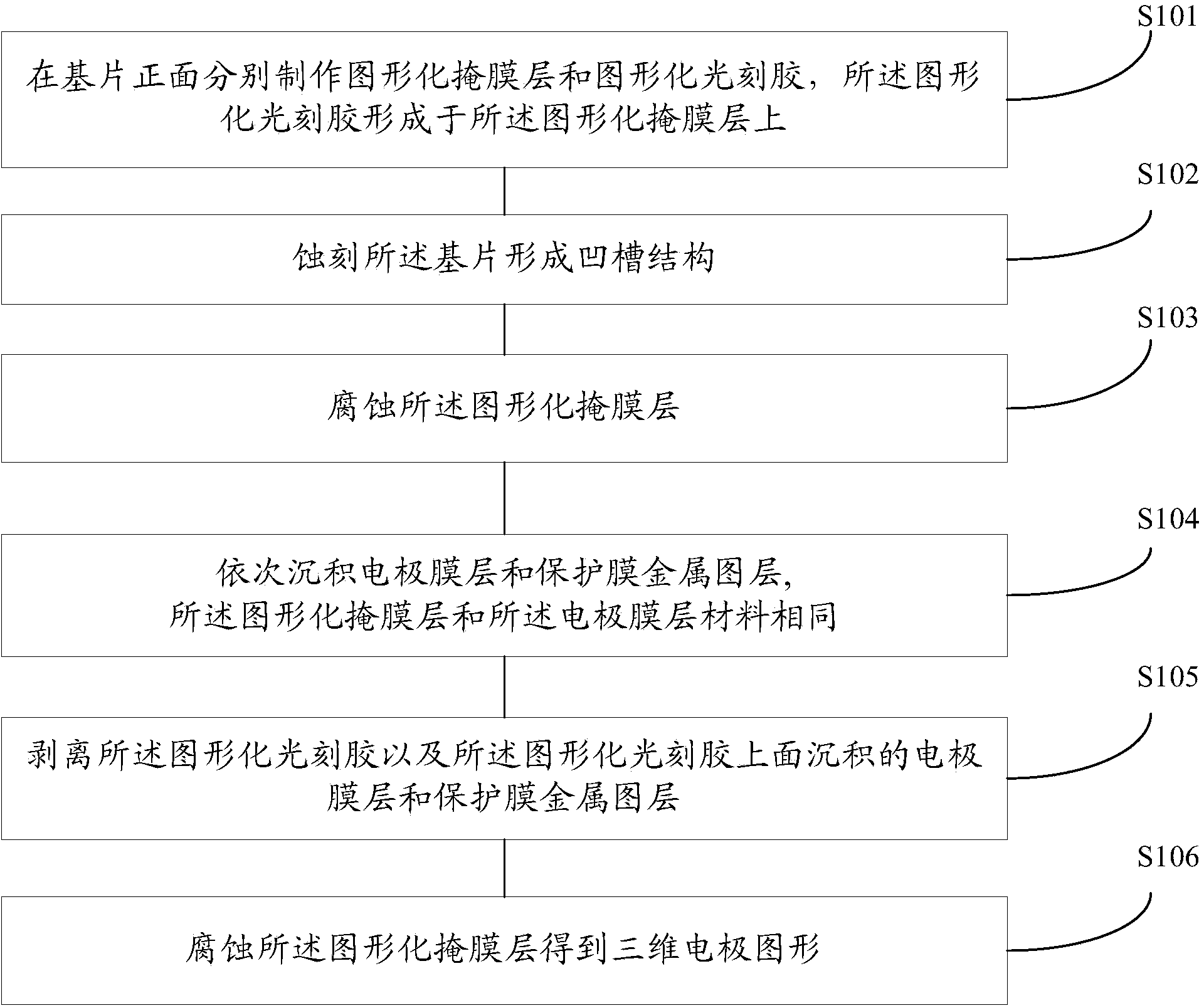

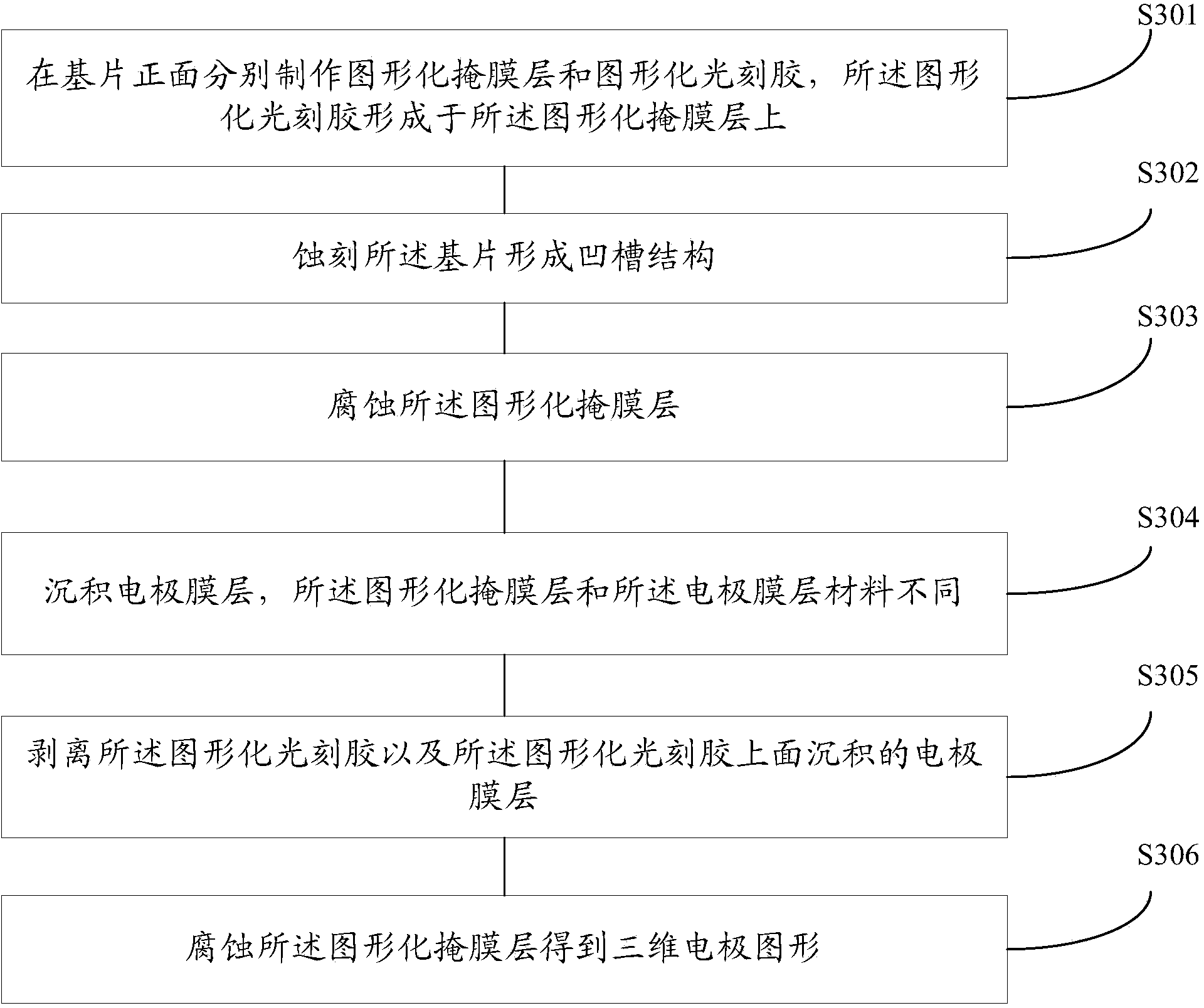

[0069] See image 3 , the three-dimensional electrode pattern manufacturing method of the third embodiment of the present invention, comprising the following steps:

[0070] S301, respectively fabricating a patterned mask layer and a patterned photoresist on the front surface of the substrate, the patterned photoresist being formed on the patterned mask layer;

[0071] S302, etching the substrate to form a groove structure;

[0072] S303, etching the patterned mask layer;

[0073] S304, depositing an electrode film layer, the material of the patterned mask ...

Embodiment approach 3

[0076] In the method of Embodiment 3, in S306, after the directly exposed patterned mask layer is etched away, the electrode film layer with a predetermined pattern is left to cover the substrate.

[0077] Compared with the method in Embodiment 1, in Embodiment 3, the materials of the patterned mask layer and the electrode film layer are different, and there is no need to deposit a protective film metal layer in step S304.

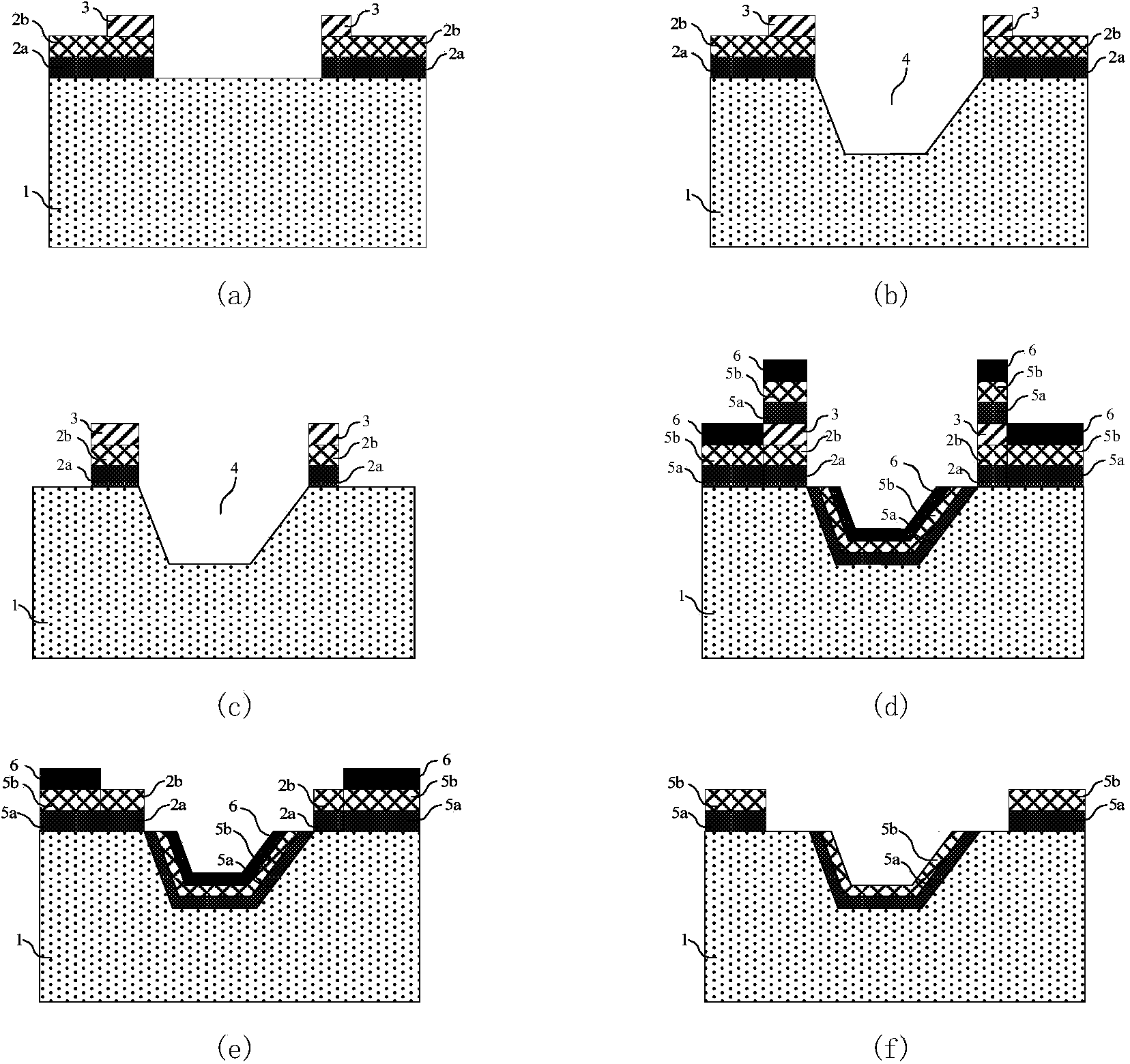

[0078] See Figure 4 (a) to (e), the principle of the three-dimensional electrode pattern manufacturing method in the fourth embodiment of the present invention is the same as that in the third embodiment.

[0079] Among them, such as Figure 4 As shown in (a), a patterned mask layer 11 and a patterned photoresist 12 are respectively formed on the front surface of the substrate 10 . Wherein, the patterned mask layer 11 includes a lower film layer 11a and an upper film layer 11b.

[0080] The steps of making a patterned mask layer 11 and a patterned phot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com