Oxygenerator adopting internal gas-circulating heat dissipation

A technology of circulating heat dissipation and oxygen generators, which is applied in the field of oxygen generators, can solve problems such as noise pollution, and achieve the effects of good noise pollution, good effect, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

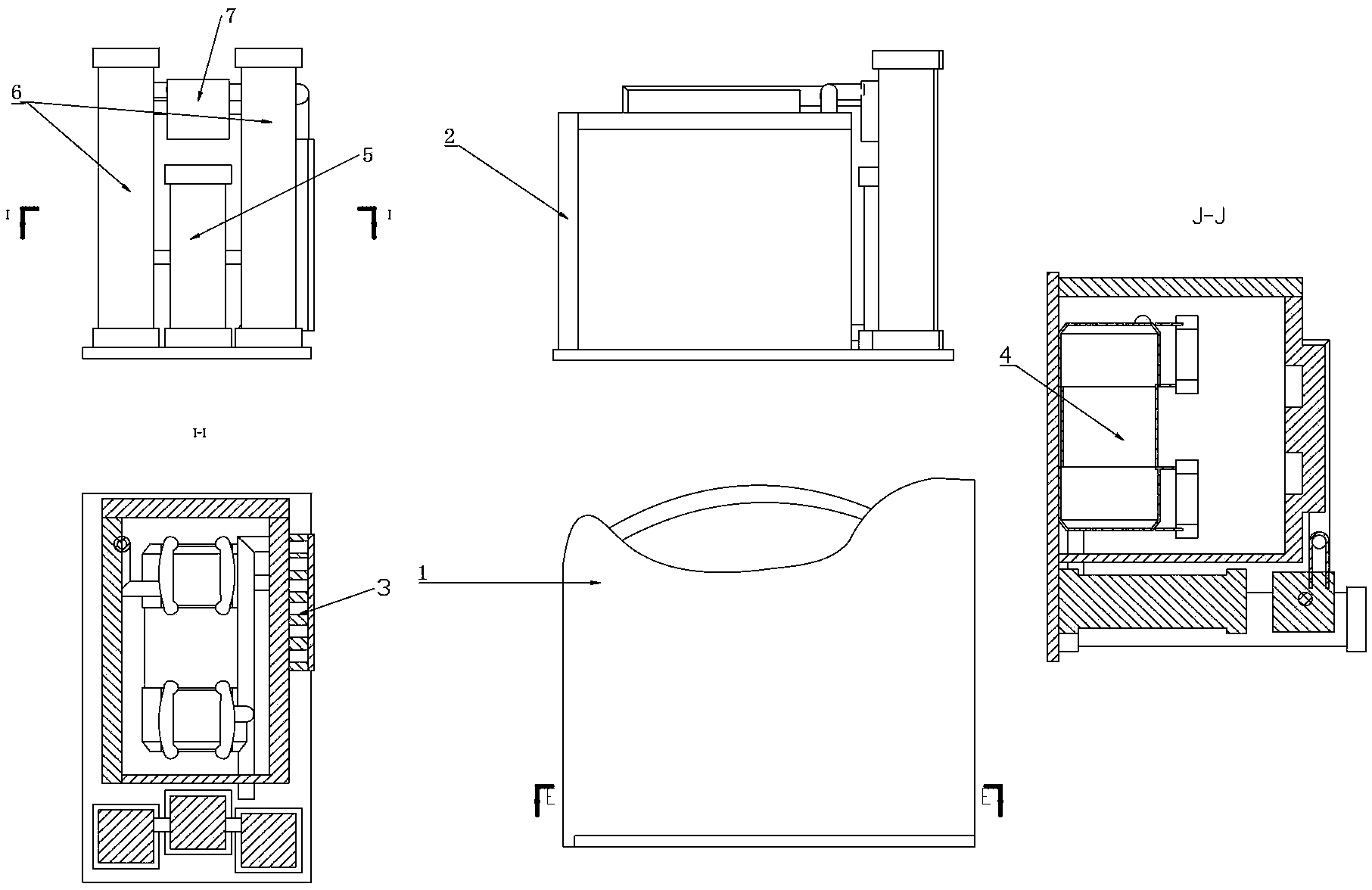

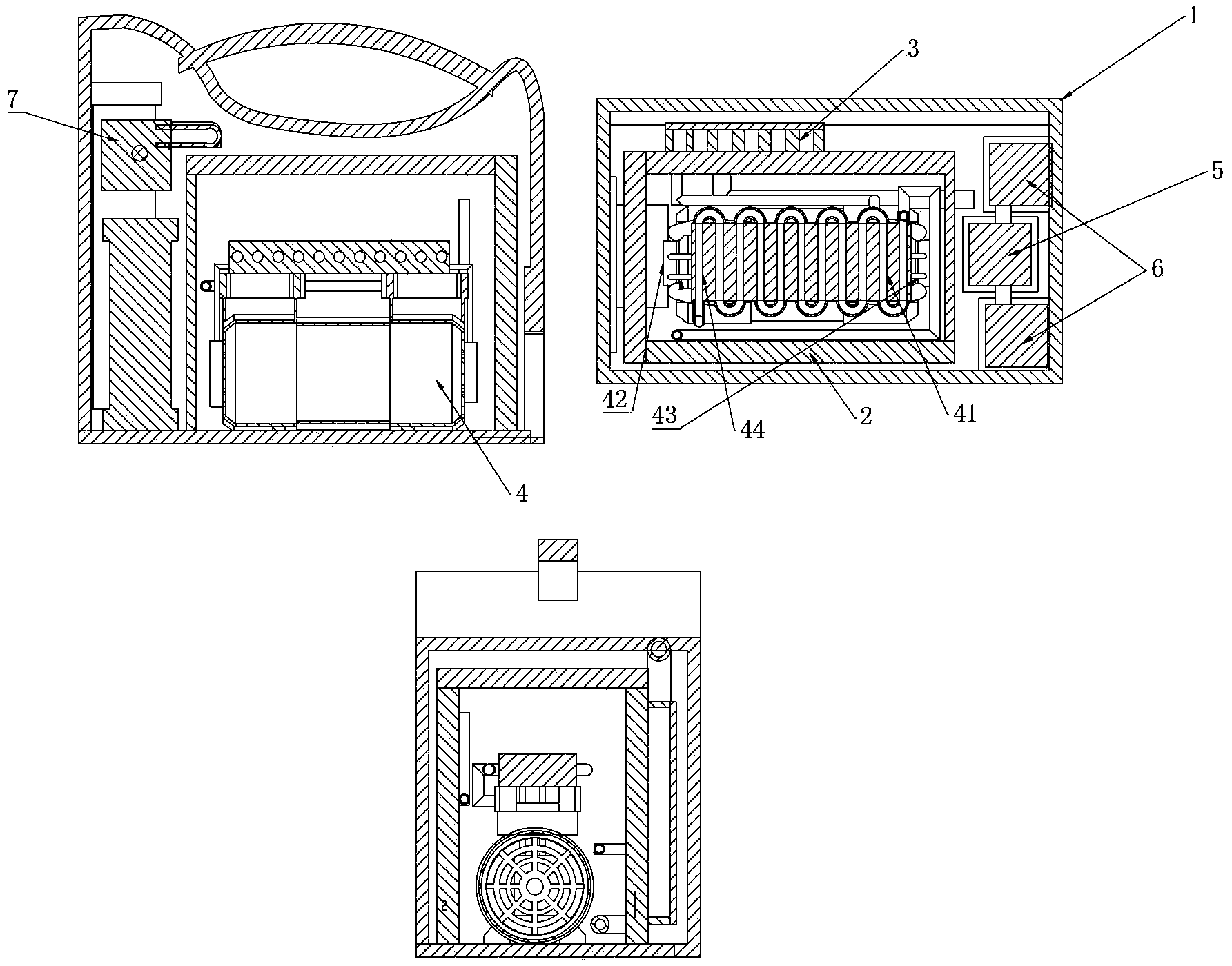

[0026] refer to figure 2 , an oxygen concentrator with internal air circulation and heat dissipation, which includes a shell 1, a noise reduction shell 2, a silencer box 3, an air compressor 4, an oxygen storage tank 5, an air collection tank 6 provided with molecular sieves, and a connection to the air collection tank 6 The multi-way valve 7, the noise reduction housing 2 are arranged in the housing 1, and the air compressor 4 is arranged in the noise reduction housing 2, and the connection relationship about oxygen production inside it is consistent with the traditional oxygen generator.

[0027] The difference is that a heat conduction block 41 is provided on the top of the air compressor 4, and the heat conduction block 41 can be fixed on the top of the air compressor 4 by a fixing mechanism, and the heat conduction block 41 and the air compressor 4 can be made into an integrated structure, or A layer of heat-conducting adhesive can be placed on the bottom of the heat-con...

Embodiment example 2

[0030] refer to image 3 , an oxygen concentrator with internal air circulation and heat dissipation, which includes a shell 1, a noise reduction shell 2, a silencer box 3, an air compressor 4, an oxygen storage tank 5, an air collection tank 6 provided with molecular sieves, and a connection to the air collection tank 6 The multi-way valve 7, the noise reduction housing 2 are arranged in the housing 1, and the air compressor 4 is arranged in the noise reduction housing 2, and the connection relationship about oxygen production inside it is consistent with the traditional oxygen generator.

[0031] The difference is that a heat conduction block 41 is provided on the top of the air compressor 4, and the heat conduction block 41 can be fixed on the top of the air compressor 4 by a fixing mechanism, and the heat conduction block 41 and the air compressor 4 can be made into an integrated structure, or A layer of heat-conducting adhesive can be placed on the bottom of the heat-cond...

Embodiment example 3

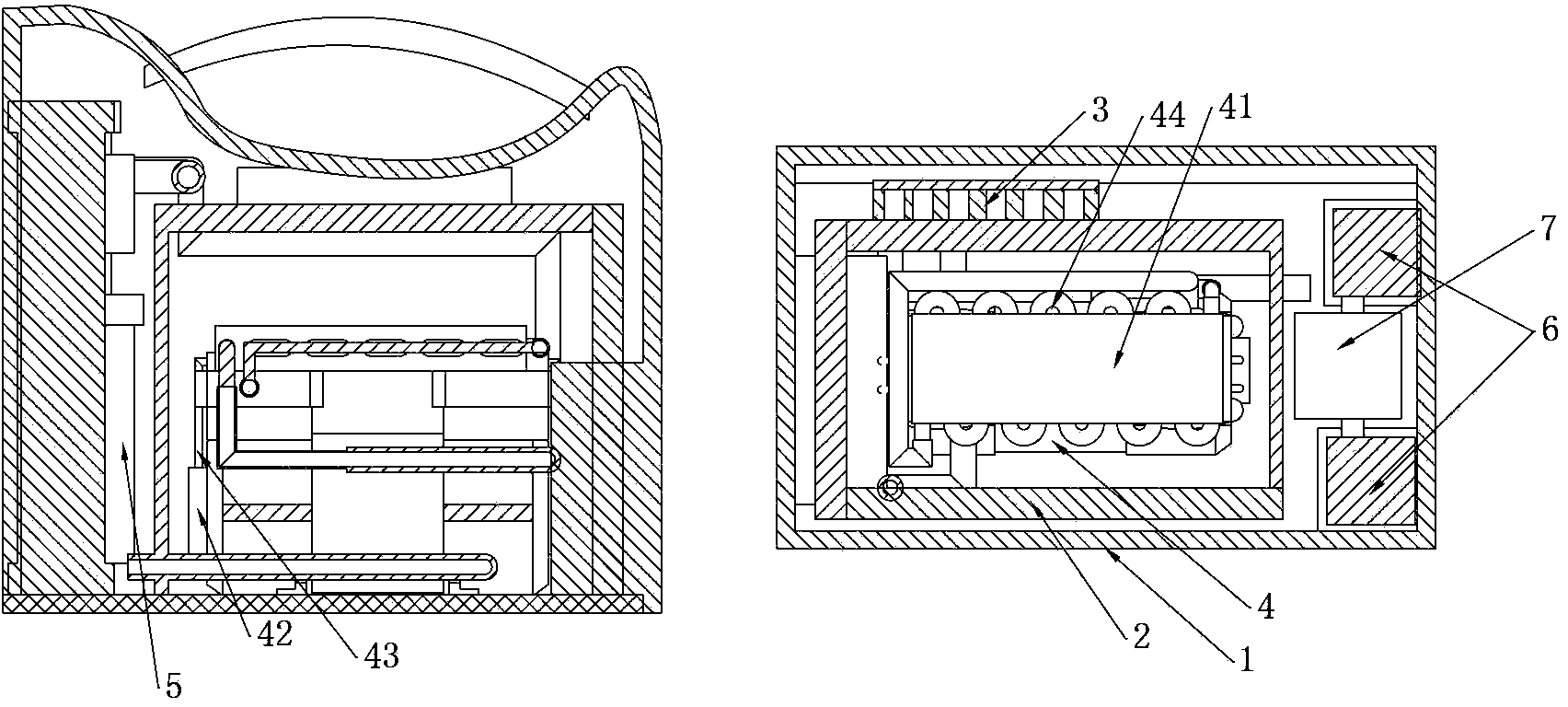

[0034] refer to Figure 4 , an oxygen concentrator with internal air circulation and heat dissipation, which includes a shell 1, a noise reduction shell 2, a silencer box 3, an air compressor 4, an oxygen storage tank 5, an air collection tank 6 provided with molecular sieves, and a connection to the air collection tank 6 The multi-way valve 7, the noise reduction housing 2 are arranged in the housing 1, and the air compressor 4 is arranged in the noise reduction housing 2, and the connection relationship about oxygen production inside it is consistent with the traditional oxygen generator.

[0035] The difference is that a heat conduction block 41 is provided on the top of the air compressor 4, and the heat conduction block 41 can be fixed on the top of the air compressor 4 by a fixing mechanism, and the heat conduction block 41 and the air compressor 4 can be made into an integrated structure, or A layer of heat-conducting adhesive can be placed on the bottom of the heat-con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com