Production technique of super-heat-insulation material silica gel

A technology of thermal insulation material and production process, applied in the direction of silicon oxide, silicon dioxide, etc., can solve the problems of instability and small pore volume, and achieve good economic and social benefits, and the effect of long-term stability of product pore volume value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

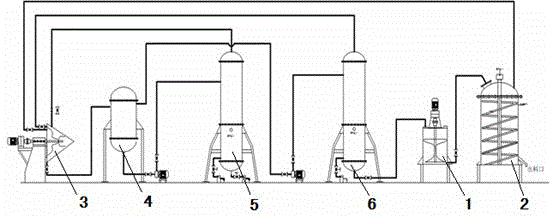

[0031] The production process of a kind of super heat insulating material silica gel of the present embodiment comprises the following production steps:

[0032] (1), preparation of hydrogel:

[0033] Using the traditional hydrogel preparation method, the SiO 2 Water glass with a concentration of 16% and dilute sulfuric acid with a concentration of 26% are pumped into the mixer 3 respectively, and are quickly mixed in the nozzle to form a sol. The reaction conditions for the formation of the sol are that the pH value reaches 2.0, the free acid is 0.2-0.7%, and the reaction temperature 20°C, flow into the gel tank, place until the sol gels, and perform aging. The aging time is 48 hours.

[0034] After aging, cut the gel into small pieces of 2.5-3.5cm, put it into the washing tank, wash it with tap water first, then with deionized water, and wash until the SO in the gel 4 2- The mass percentage concentration is less than 0.1%, and it is reserved.

[0035] (2) Formation of o...

Embodiment 2

[0046] The production process of a kind of super heat insulating material silica gel of the present embodiment comprises the following production steps:

[0047] (1), preparation of hydrogel:

[0048] Using the traditional hydrogel preparation method, the SiO 2 Water glass with a concentration of 18% and dilute sulfuric acid with a concentration of 28% are pumped into the mixer 3 respectively, and are quickly mixed in the nozzle to form a sol. The reaction conditions for sol generation are as follows: pH value 2.2, free acid 0.2-0.7%, reaction temperature At 25°C, flow into the gel tank, place until the sol gels, and perform aging. The aging time is 45 hours.

[0049] After aging, cut the gel into small pieces of 2.5-3.5cm, put it into the washing tank, wash it with tap water first, then with deionized water, and wash until the SO in the gel 4 2- The mass percentage concentration is less than 0.1%, and it is reserved.

[0050] (2) Formation of organogel:

[0051] Put the h...

Embodiment 3

[0061] The production process of a kind of super heat insulating material silica gel of the present embodiment comprises the following production steps:

[0062] (1), preparation of hydrogel:

[0063] Using the traditional hydrogel preparation method, the SiO 2 Water glass with a concentration of 20% and dilute sulfuric acid with a concentration of 30% are pumped into the mixer 3 respectively, and are quickly mixed in the nozzle to form a sol. The reaction conditions for the formation of the sol are that the pH value is 2.5, the free acid is 0.2-0.7%, and the reaction temperature is 30°C, flow into the gel tank, place until the sol gels, and perform aging. The aging time is 40 hours.

[0064] After aging, cut the gel into small pieces of 2.5-3.5cm, put it into the washing tank, wash it with tap water first, then with deionized water, and wash until the SO in the gel 4 2- The mass percentage concentration is less than 0.1%, and it is reserved.

[0065] (2) Formation of org...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com