Novel porous high-specific-surface aluminum hydroxide material

A technology of aluminum hydroxide and high specific surface, applied in the directions of alumina/aluminum hydroxide, inorganic chemistry, aluminum compounds, etc., can solve the problem of high preparation cost, achieve the effects of simple operation, stable pore volume, and improved production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

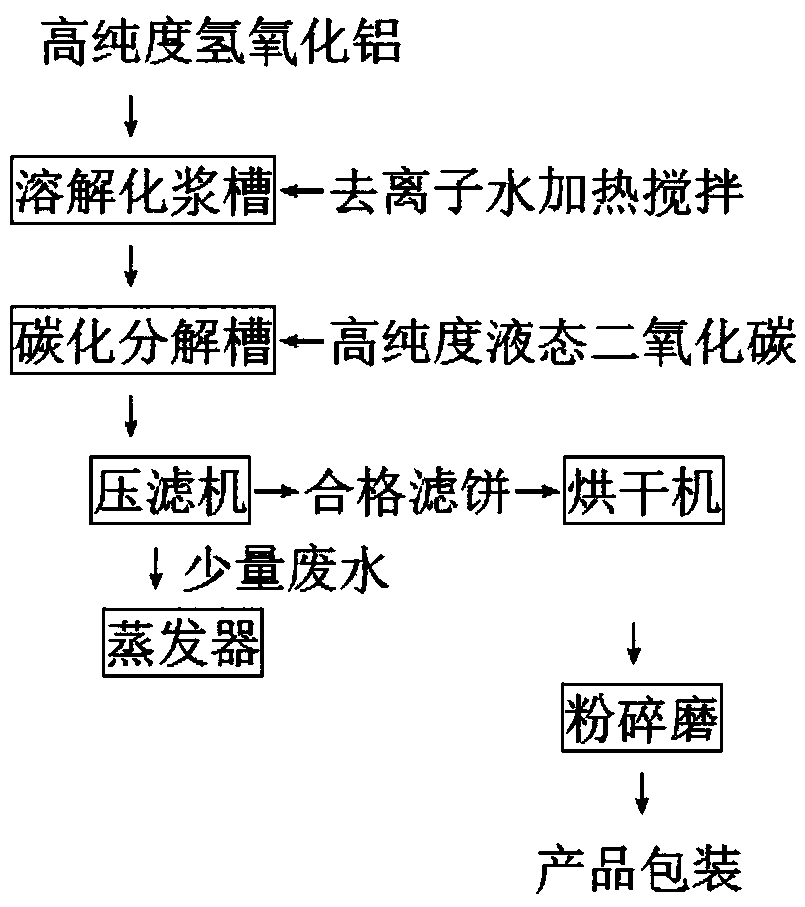

[0029] The new porous aluminum hydroxide material with high specific surface is prepared by the following method:

[0030] 1) Take aluminum hydroxide and dissolve it with 2 times the mass of deionized water under steam heating at 120°C, adjust the concentration of aluminum oxide in the solution to 25g / L;

[0031] 2) Add the product obtained in step 1) to the carbonization tower, and at the same time add liquid carbon dioxide to the carbonization tower for gelation reaction to obtain modified aluminum hydroxide slurry; the gelation reaction temperature is 20°C, and the gelation reaction time 20min;

[0032] 3) The modified aluminum hydroxide slurry obtained in step 2) is added to the filter press for solid-liquid separation, the liquid phase is discarded, the washing liquid is added to the filter press, and then the solid-liquid separation is performed again, and the solid phase is taken as Modified aluminum hydroxide product;

[0033] 4) Add the product obtained in step 3) to a tray ...

Embodiment 2

[0049] The new porous aluminum hydroxide material with high specific surface is prepared by the following method:

[0050] 1) Take aluminum hydroxide and dissolve it with 2 times the mass of deionized water under steam heating at 120°C, adjust the concentration of aluminum oxide in the solution to 25g / L;

[0051] 2) Add the product obtained in step 1) to the carbonization tower, and at the same time add liquid carbon dioxide to the carbonization tower for gelation reaction to obtain modified aluminum hydroxide slurry; the gelation reaction temperature is 20°C, and the gelation reaction time 20min;

[0052] 3) The modified aluminum hydroxide slurry obtained in step 2) is added to the filter press for solid-liquid separation, the liquid phase is discarded, the washing liquid is added to the filter press, and then the solid-liquid separation is performed again, and the solid phase is taken as Modified aluminum hydroxide product.

Embodiment 3

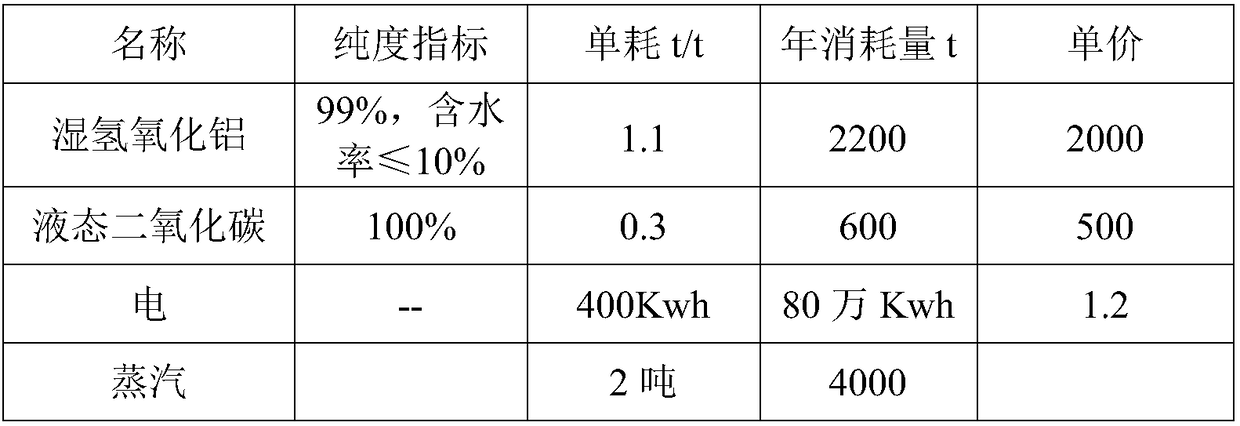

[0054] 1. Raw material preparation

[0055] Purchasing high-purity aluminum hydroxide, dissolving it in a water tank, steaming to raise temperature and heating to dissolve, to prepare aluminum hydroxide mother liquor, and then blending to a suitable concentration according to process requirements. (4T aluminum hydroxide is added to 8T deionized water to dissolve, raise the temperature to 120 degrees and stir to dissolve. After dissolution, a mother liquor with an alumina content of 350g / l is obtained. Then it is formulated according to the alumina content of 23g / l)

[0056] 2. Carbonization and decomposition

[0057] The mother liquor of aluminum hydroxide with a concentration of 25g / l of alumina content is pumped into the carbonization tower. After the compressed air flow is 250, liquid carbon dioxide is introduced. After gelation, the temperature is controlled to 20 degrees and the gelation time is 20. Minutes, a modified aluminum hydroxide slurry was prepared.

[0058] 3. Press fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com