Xenon/krypton adsorption separation method based on Hofmann type metal-organic framework material

An organic framework, adsorption separation technology, applied in separation methods, non-metallic elements, dispersed particle separation, etc., can solve problems that are difficult to meet the requirements, and achieve the effects of enhanced adsorption affinity, high separation selectivity, and excellent chemical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

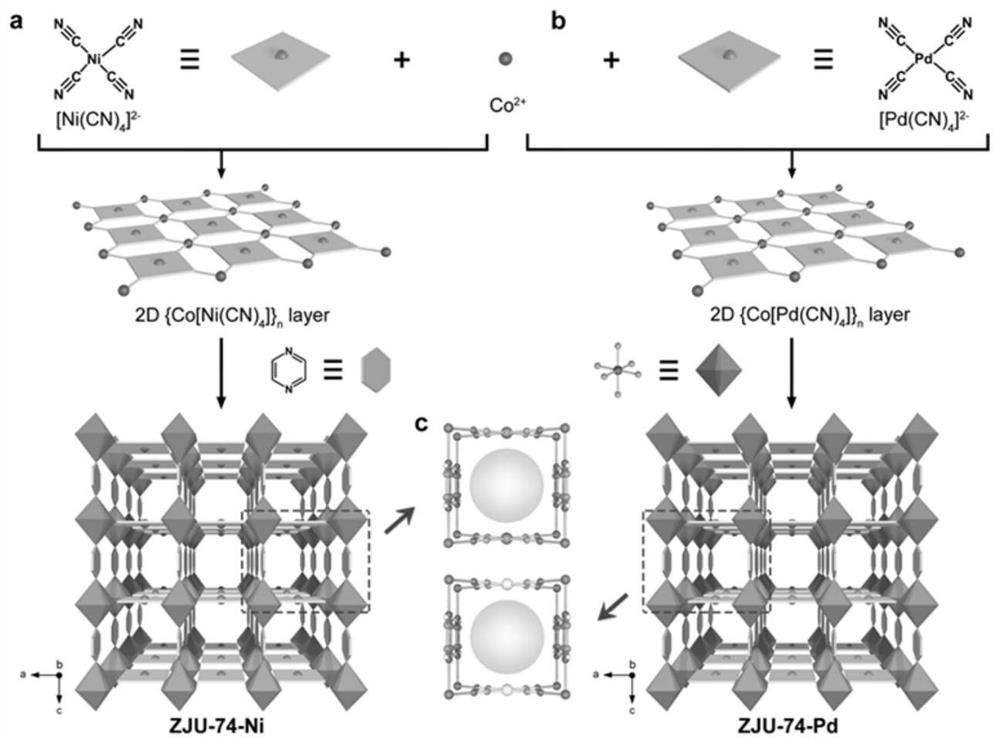

[0046] Dissolve 0.5 mmol of potassium tetracyanonickelate in water, 0.5 mmol of cobalt nitrate hexahydrate and 0.5 mmol of pyrazine in a methanol:water mixed solution with a volume ratio of 1:1, and then heat and stir at 30°C Under certain conditions, the potassium tetracyanonickelate solution was dropped dropwise into the mixed solution of cobalt nitrate and pyrazine, stirred for 3 hours, suction filtered after the reaction, and washed with deionized water and methanol in sequence to obtain ZJU-74-Ni .

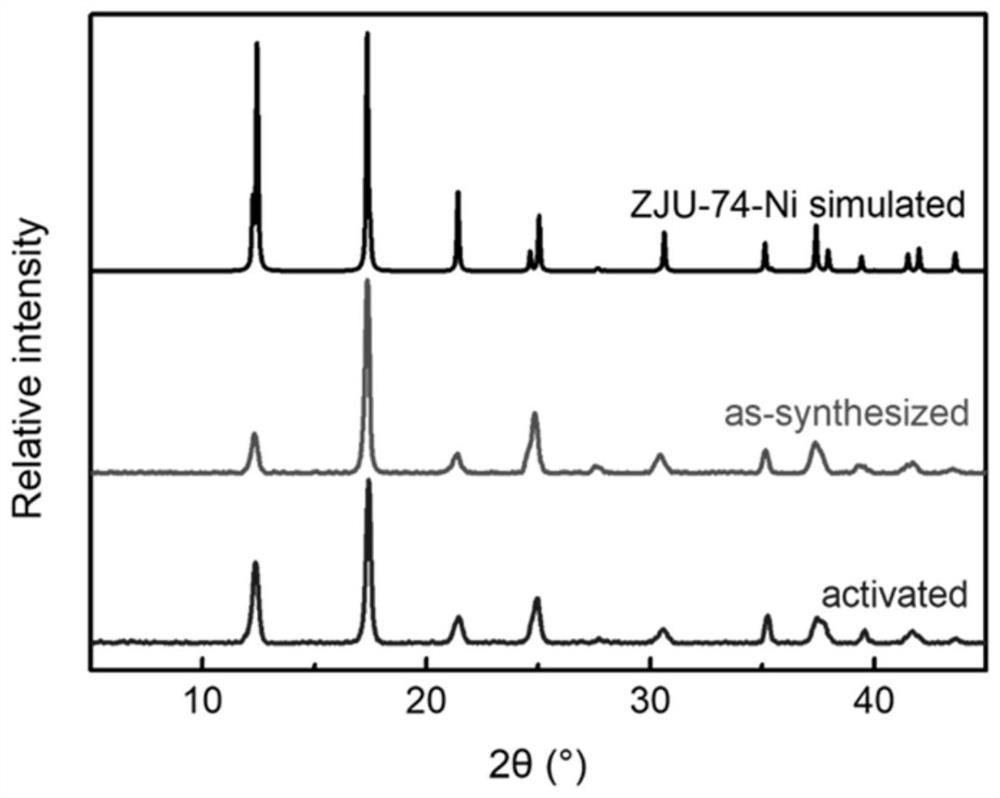

[0047] The schematic diagram of the crystal structure of the material is shown in figure 1 , see the PXRD pattern figure 2 . The obtained homogeneous crystalline material was exchanged several times in anhydrous acetone by the solvent exchange method, with an interval of at least 2 hours each time, and then activated at room temperature for 24 hours, and then activated at 90°C for 12 hours to obtain ZJU- 74a—Ni.

Embodiment 2

[0049] Dissolve 0.5 mmol of potassium tetracyanopladate in water, 0.5 mmol of cobalt nitrate hexahydrate and 0.5 mmol of pyrazine in a methanol:water mixed solution with a volume ratio of 1:1, and then heat and stir at 30°C Under certain conditions, the potassium tetracyanopladate solution was dropped dropwise into the mixed solution of cobalt nitrate and pyrazine, stirred for 3 hours, suction filtered after the reaction, and washed with deionized water and methanol in sequence to obtain ZJU-74-Pd .

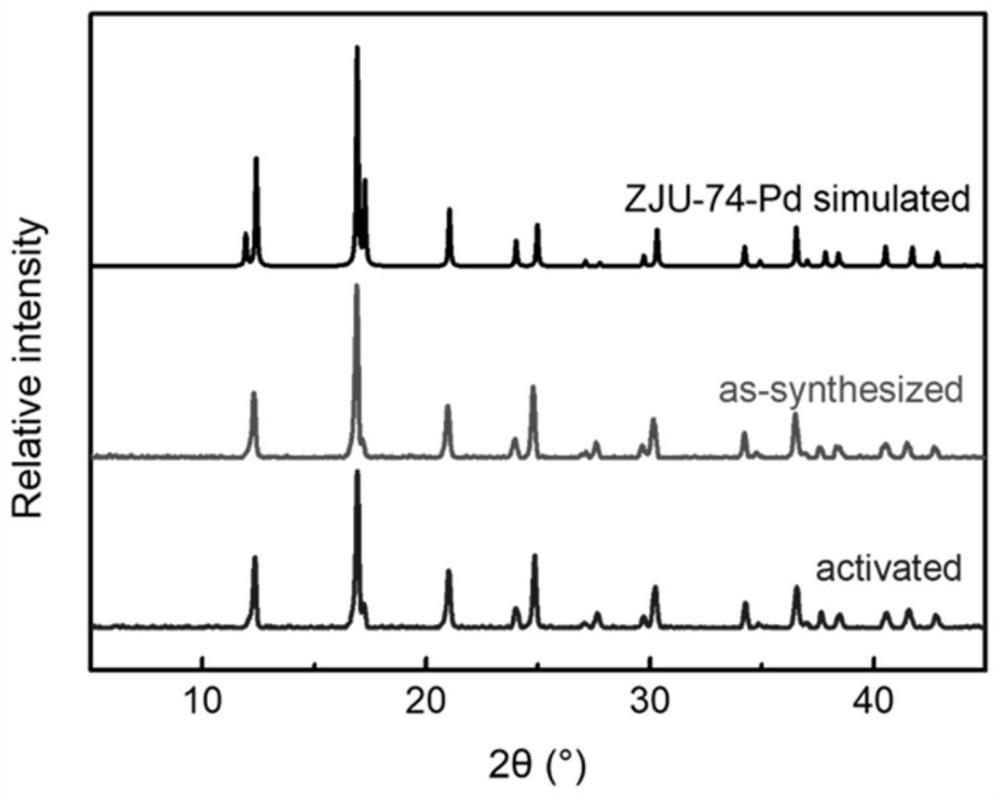

[0050] The schematic diagram of the crystal structure of the material is shown in figure 1 , see the PXRD pattern image 3 . The obtained homogeneous crystalline material was exchanged several times in anhydrous acetone by the solvent exchange method, with an interval of at least 2 hours each time, and then activated at room temperature for 24 hours, and then activated at 90°C for 12 hours to obtain ZJU- 74a-Pd.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com