Method for producing all-element liquid organic fertilizer by adopting slag water generated in biomass direct-combustion power generation

A biomass, all-element technology, applied in the application, fertilization device, fertilizer mixture and other directions, can solve the problem of low impact load, and achieve the effect of improving fertilizer efficiency, benefiting crop utilization, and improving stress resistance and quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

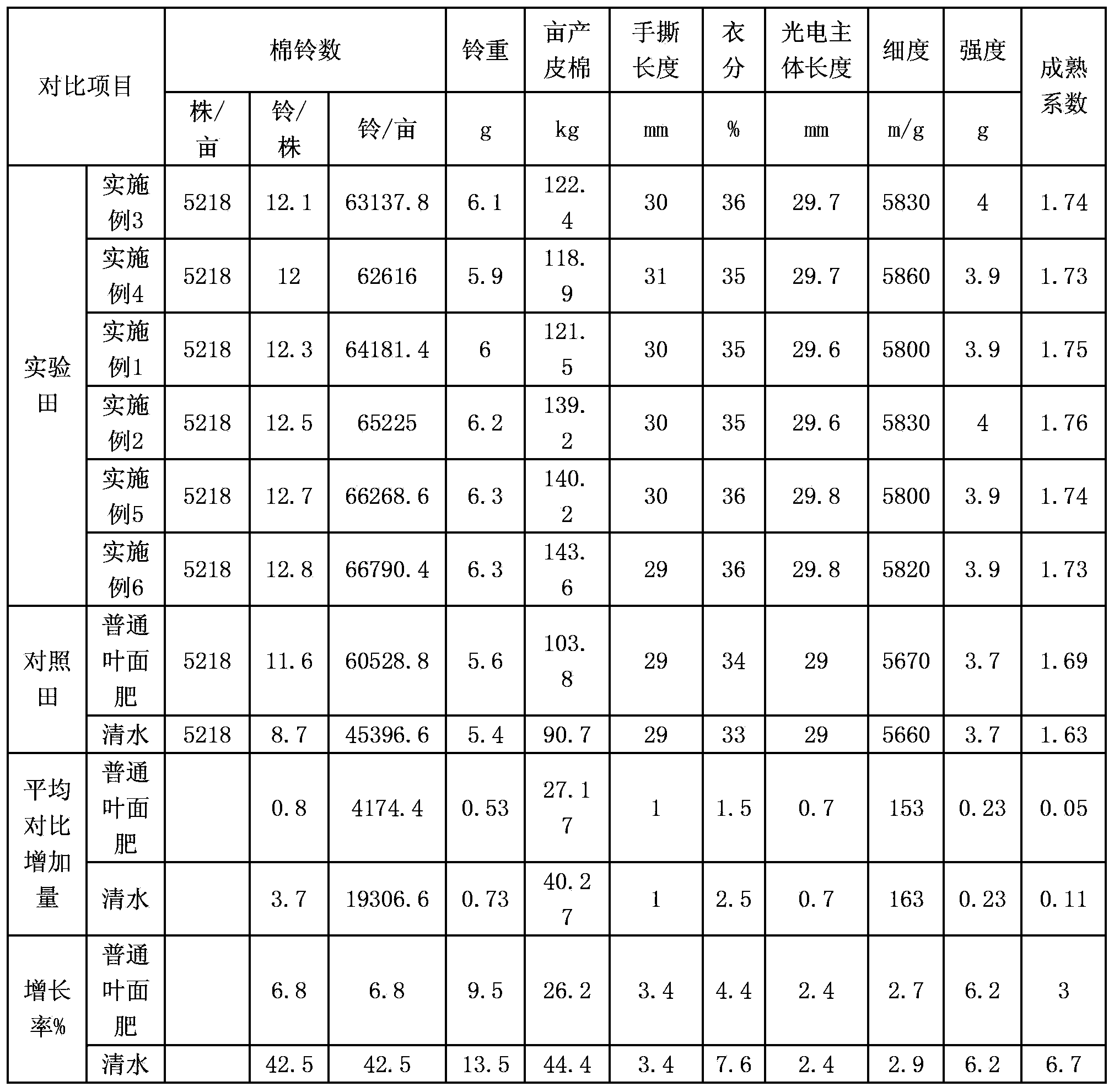

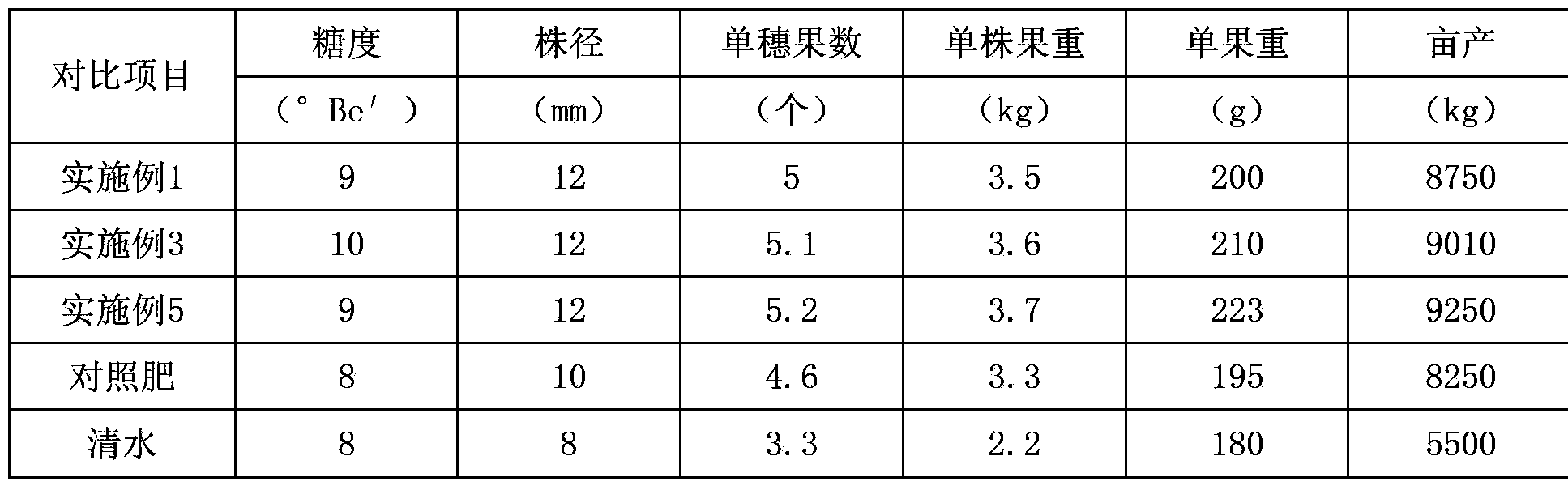

Examples

Embodiment 1

[0039] The method for producing all-element liquid organic fertilizer with biomass direct combustion power generation slag water comprises the following steps:

[0040] Add 55kg of humic acid to 1000kg of biomass direct combustion power generation slag water, adjust the pH value to 7.5, and then concentrate in a low-temperature vacuum at a vacuum degree of 82.7KPa and a temperature of 45°C to obtain 280kg of a paste liquid, which is passed through a 200-mesh nylon filter Filtrate, take the filtrate, and make all-element liquid organic fertilizer;

[0041] After testing, the above-mentioned all-element liquid organic fertilizer contains the following elements required for plant growth, all in weight percentage:

[0042] Humic acid=5.0%, N=0.2%, P 2 o 5 =2.0%, K 2 O=12.0%, S+Mg+Ca=6.0%, Fe+Mn+Zn+Cu+Mo+B=3.2%.

[0043] The above-mentioned low-temperature vacuum concentration is heated by circulating water. The heat of the circulating water comes from the waste heat of the bio...

Embodiment 2

[0045] The method for producing all-element liquid organic fertilizer with biomass direct combustion power generation slag water comprises the following steps:

[0046] 1000kg of biomass direct combustion power generation slag water was concentrated in a low-temperature vacuum at a vacuum degree of 90.6KPa and a temperature of 55°C, and then 40kg of amino acids were added to adjust the pH value to 6.5 to obtain 260kg of a paste liquid, which was filtered through a 180-mesh nylon filter and taken The filtrate is used to obtain a full-element liquid organic fertilizer;

[0047] The above-mentioned low-temperature vacuum concentration is heated by circulating water. The heat of the circulating water comes from the waste heat of the biomass direct-fired power generation combustion furnace. The steam after the low-temperature vacuum concentration is cooled and recovered and used as circulating water. A total of 780kg of cooling water is recovered.

[0048] After testing, the above-...

Embodiment 3

[0051] The method for producing all-element liquid organic fertilizer with biomass direct combustion power generation slag water comprises the following steps:

[0052]Add 10kg of humic acid, 5kg of alginic acid, 10kg of amino acid, 6kg of glutenic acid, and 5kg of citric acid to 1000kg of biomass direct combustion power generation slag water, adjust the pH value to 6.0, and then concentrate in a low-temperature vacuum at a vacuum degree of 89.0KPa and a temperature of 50°C , make 185kg of pasty liquid, filter through 200 mesh nylon filter screens, get filtrate, make full-element liquid organic fertilizer.

[0053] After testing, the above-mentioned all-element liquid organic fertilizer contains the following elements required for plant growth, all in weight percentage:

[0054] Compound acid organic matter (humic acid + alginic acid + amino acid + gluten acid + citric acid) = 10.0%, N = 0.35%, P 2 o 5 =2.1%, K 2 O=12.6%, S+Mg+Ca=6.8%, Fe+Mn+Zn+Cu+Mo+B=3.4%;

[0055] The a...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap