Siphoning type reservoir desilting and screening device and use method thereof

A screening equipment and siphon-type technology, which can be used in earth movers/shovels, mechanically driven excavators/dredgers, construction, etc., and can solve problems such as unsatisfactory dredging effect of dam bottom holes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

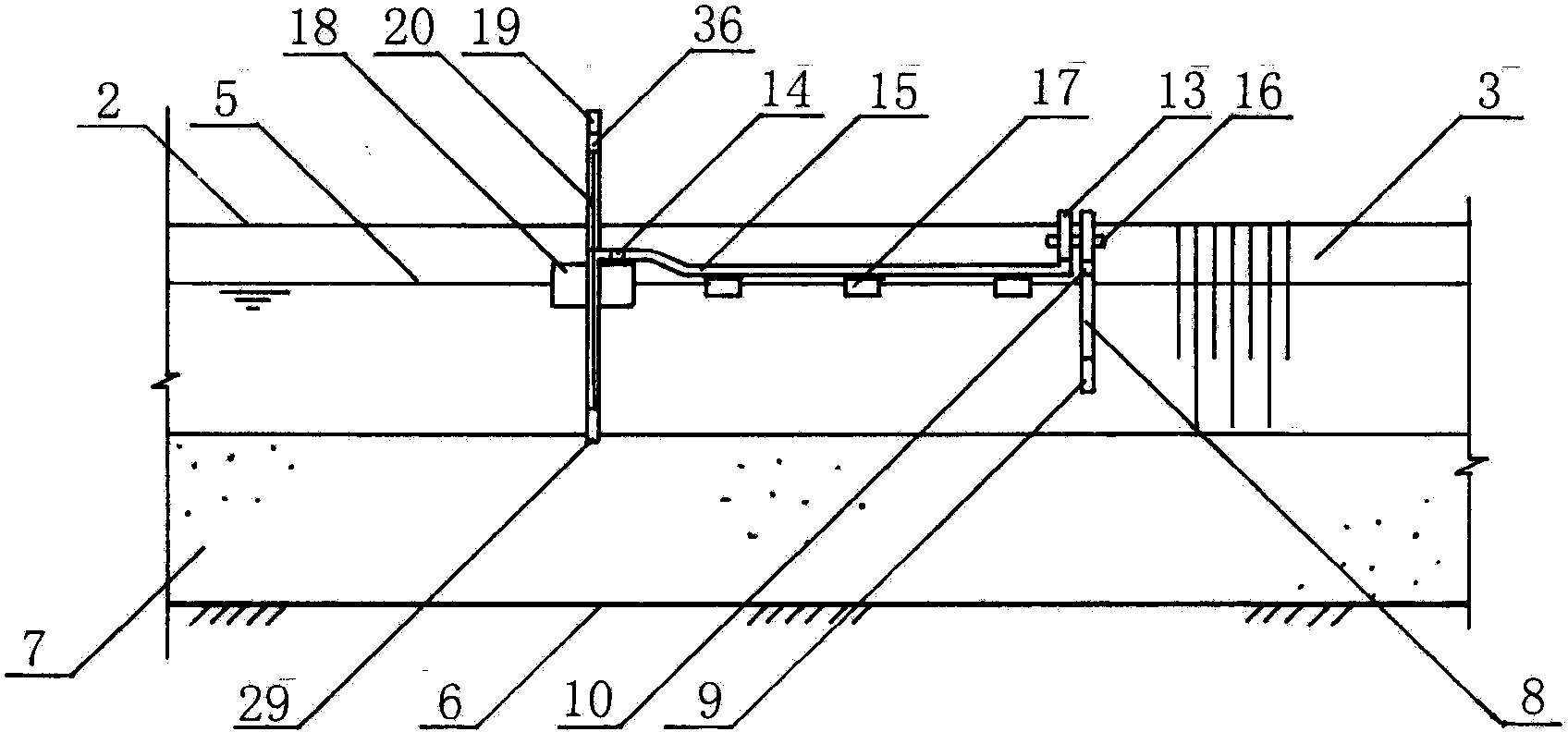

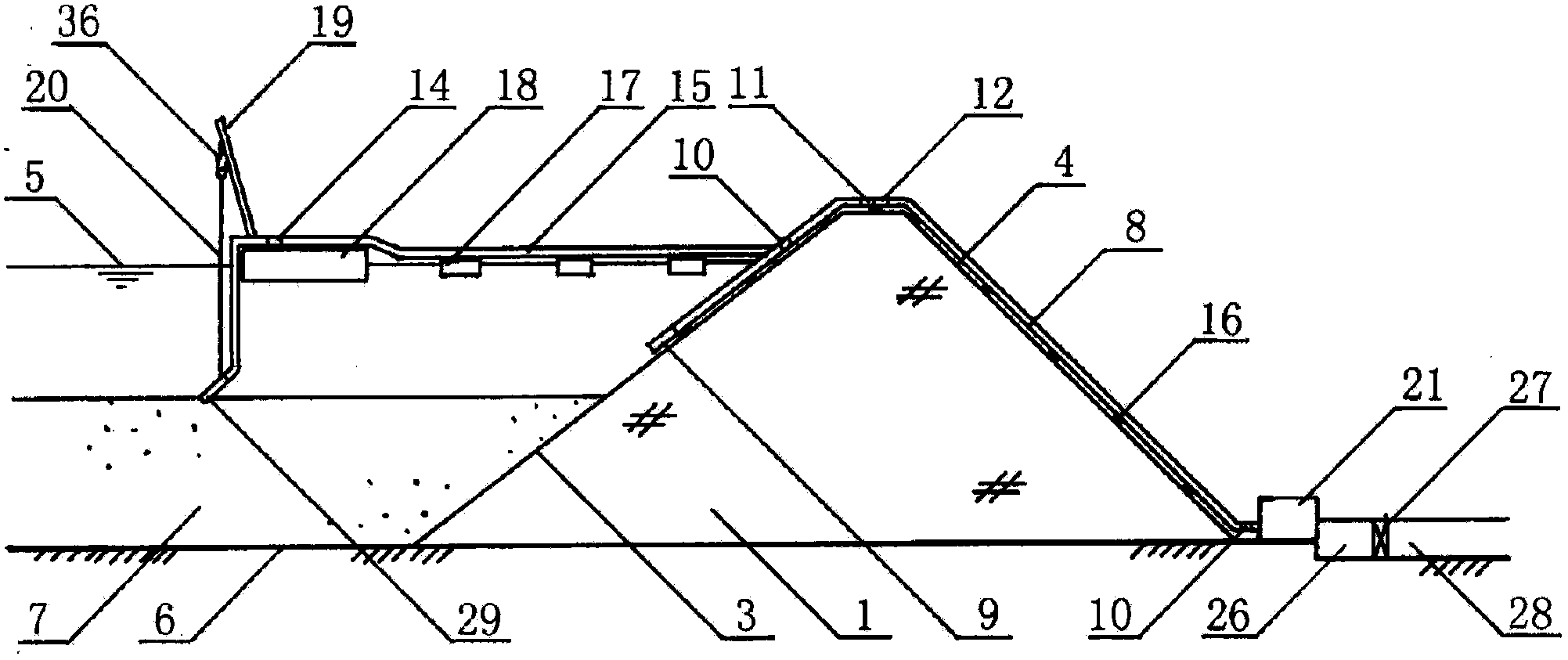

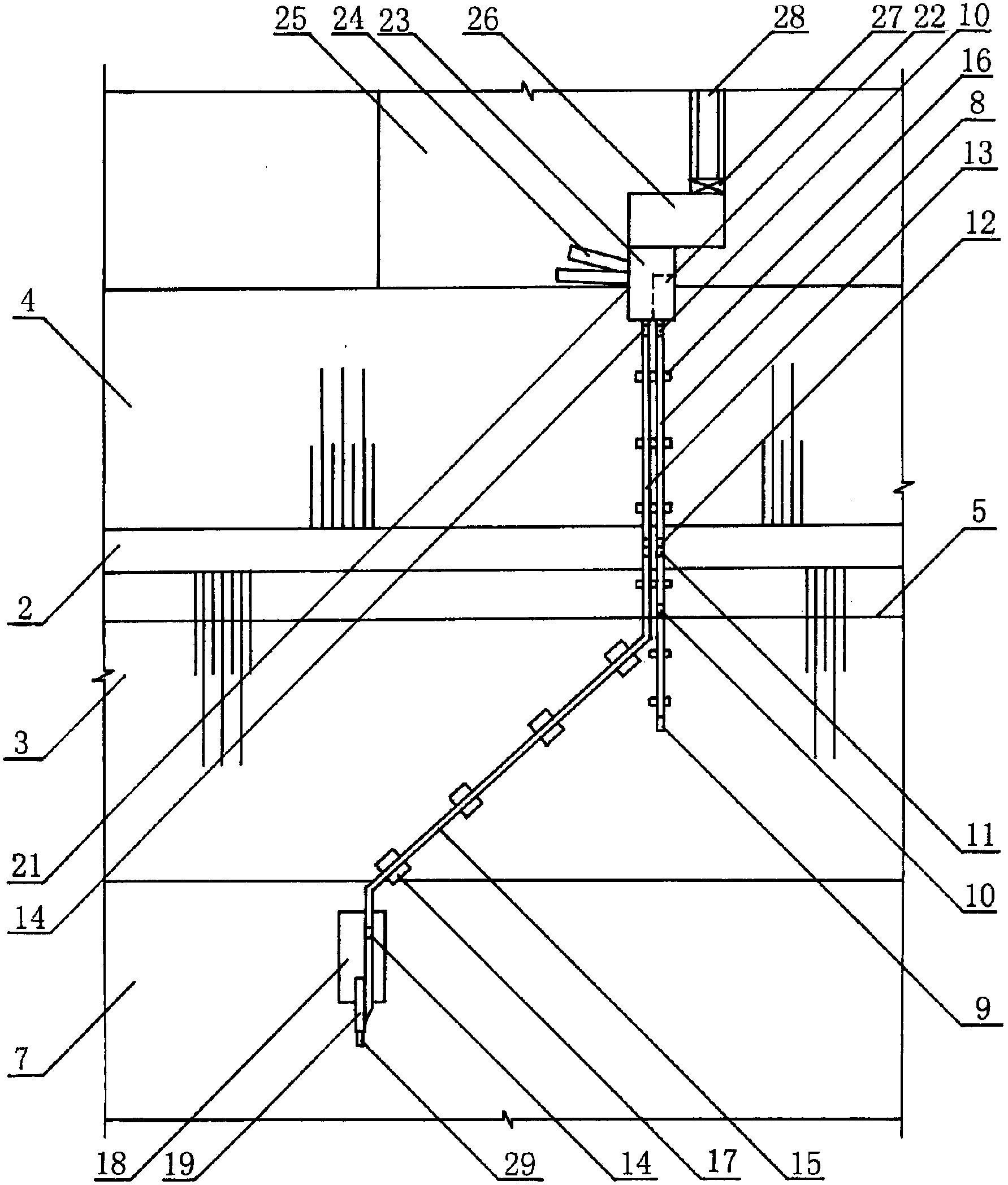

[0032] see Figure 1 to Figure 9 , is a kind of siphon type reservoir dredging and screening equipment of the present invention, comprising swing stirring mud suction nozzle 29, suction mud state sensor 36, hydraulic sludge screening equipment 21 etc., is characterized in that: in reservoir dam 1 On the upstream dam slope 3, the dam crest 2, and the downstream dam slope 4, a row of town piers 16 at equidistant intervals is arranged perpendicular to the dam axis, and water suction pipes 8 and mud suction pipes 13 are installed side by side on these town piers 16. A row of floating boats 17 on the water surface 5 of the reservoir is equipped with a mud suction hose 15, and there is a mud suction state sensor 36 at the top of the pole crane 19 at the bow of a motor ship 18, and there is a fixed pulley connected with the mud suction state sensor 36. A wire rope 20 of the pole crane 19 passes through the fixed pulley to lift the swing and stir the mud suction nozzle 29, and the swi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com