Underwater crusher

A technology of a crushing device and a crushing shaft, which is applied in the field of devices for crushing underwater sediments and mineral layers, can solve the problems of easy wear and tear of gear cutters, high replacement cost, and small collection volume, and achieves improved collection efficiency, long service life, and difficulty in wear effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

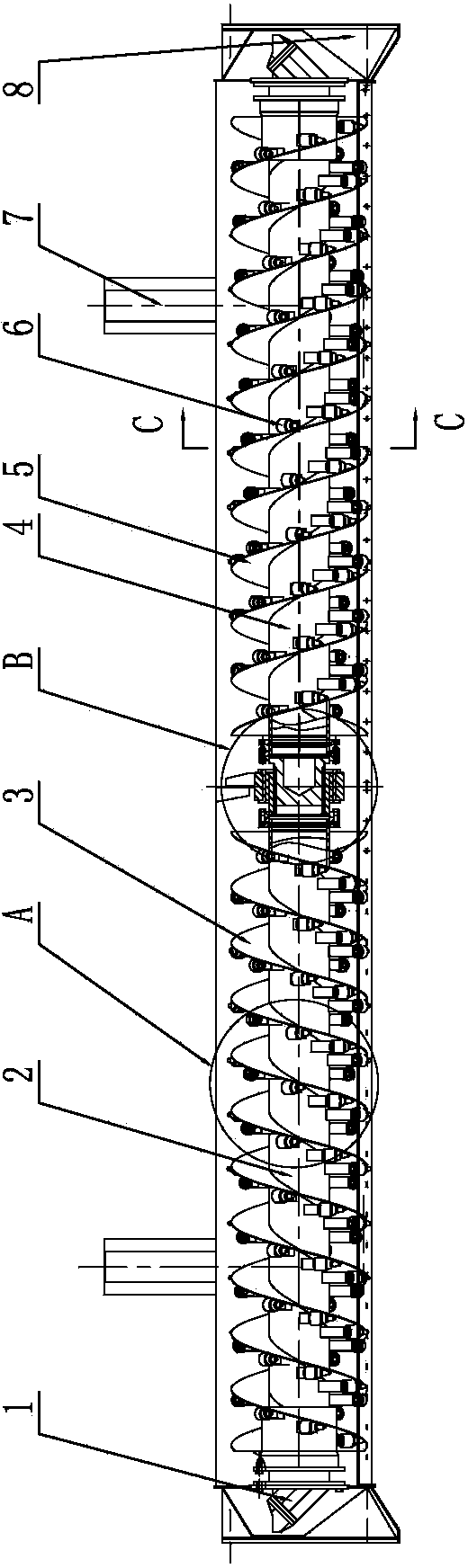

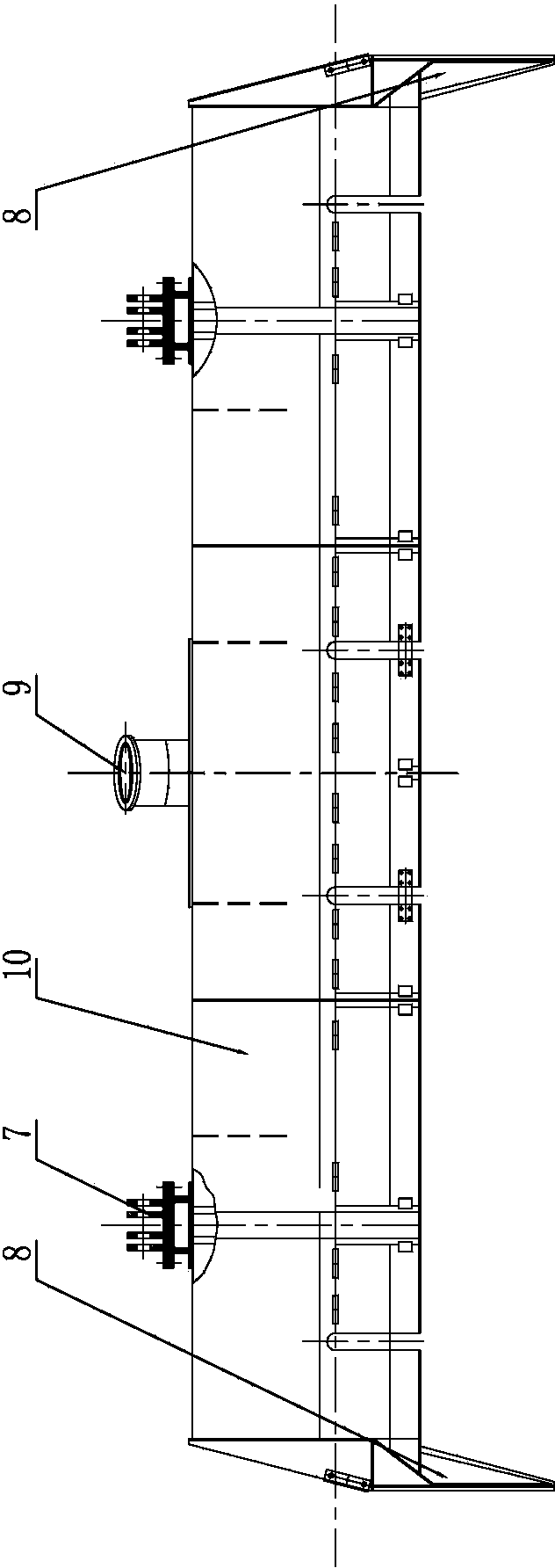

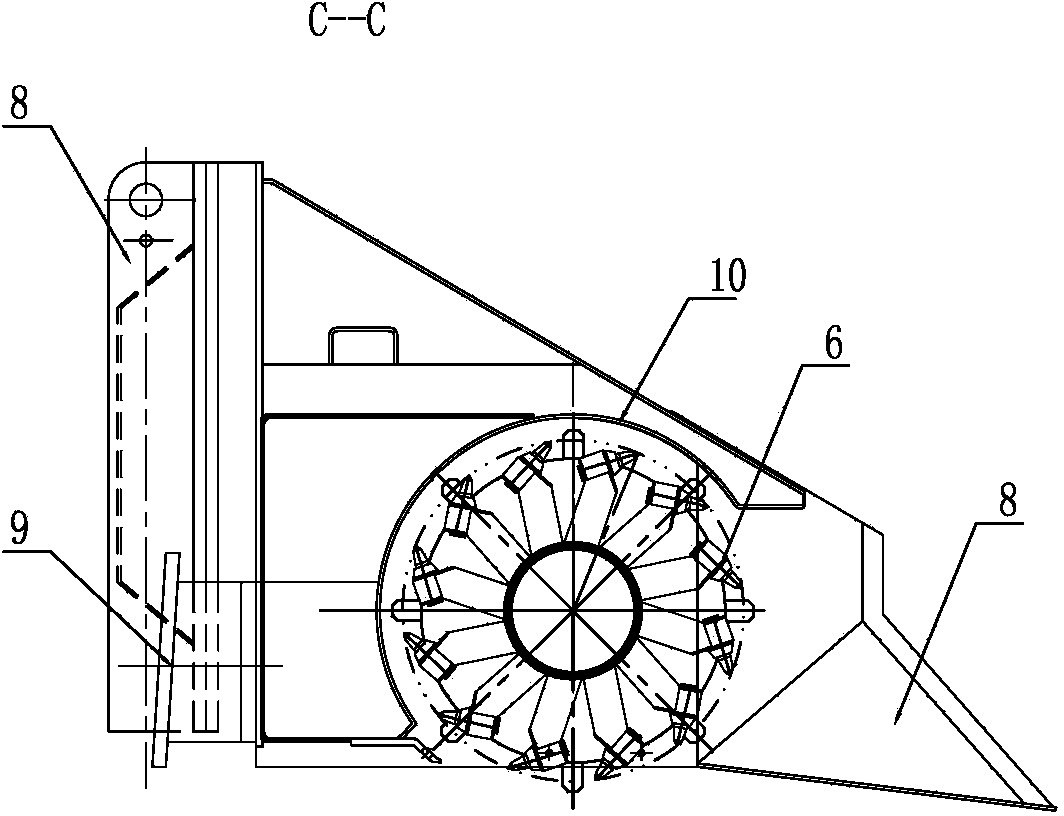

[0018] As shown in the figure, it is an underwater crushing device, including a tool holder 8, which is provided with a mounting bracket 7, through which the device can be fixed on the hull as a whole, and the two ends of the tool holder 8 are forward Extending to form a sharp angle, in order to better cut into the sedimentary layer or ore layer at the bottom of the water, a crushing shaft is rotatably installed horizontally on the tool holder 8, and the crushing shaft is connected with a driving mechanism. A hydraulic motor 1; the crushing shaft is provided with a spiral propulsion blade, the spiral propulsion blade is a three-headed spiral blade, and the spiral propulsion blade includes a left blade 3 and a right blade 5 that rotate in opposite directions, and the left blade 3 is located on the left side of the crushing shaft. On the half side, the right blade 5 is located on the right half of the crushing shaft. There are also several picks 6 on the crushing shaft. The picks...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com