A high-low-speed shaft turning device for a high-power wind turbine and its application method

A technology for wind turbines and cranking devices, which is applied to wind turbine components, wind energy power generation, wind turbines, etc., can solve the problems of high labor demand and difficult cranking, achieve less space occupation, solve cranking difficulties, and reduce installation. The effect of space requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

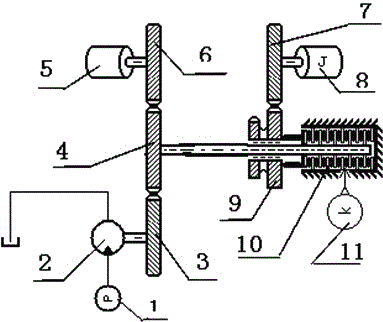

[0018] Such as figure 1 As shown, the high and low speed shaft turning device of the high-power wind turbine includes a main gear box, an external hydraulic source 1, a hydraulic motor 2, a motor shaft gear 3, and an intermediate gear 4. Wind wheel 5, low-speed gear 6, high-speed gear 7, brake disc 8, intermediate shift gear 9, shift mechanism 10, shift controller 11; the hydraulic motor 2 is installed on the main gearbox , the external hydraulic source 1 and the hydraulic motor 2 are connected through hydraulic pipes, the hydraulic motor 2 is coaxially connected with the motor shaft gear 3, the motor shaft gear 3 meshes with the intermediate stage gear 4, and the intermediate stage gear 4 meshes with the low speed stage The gear 6 meshes, and the low-speed gear 6 is connected to the wind wheel 5; the intermediate gear 4 and the intermediate shift gear 9 are movably connected through two rotating shafts, and the intermediate shift gear 9 is connected to the shifting mechanism ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com