Gas holder piston oil groove separating weir

A gas tank and piston technology, which is applied in the field of gas tank, can solve the problems of the wear of the weir sliding plate and the poor ability to bear the differential pressure of canvas oil in the weir, and achieve the effects of reducing friction and wear, avoiding the problem of gas leakage and reducing the pressure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

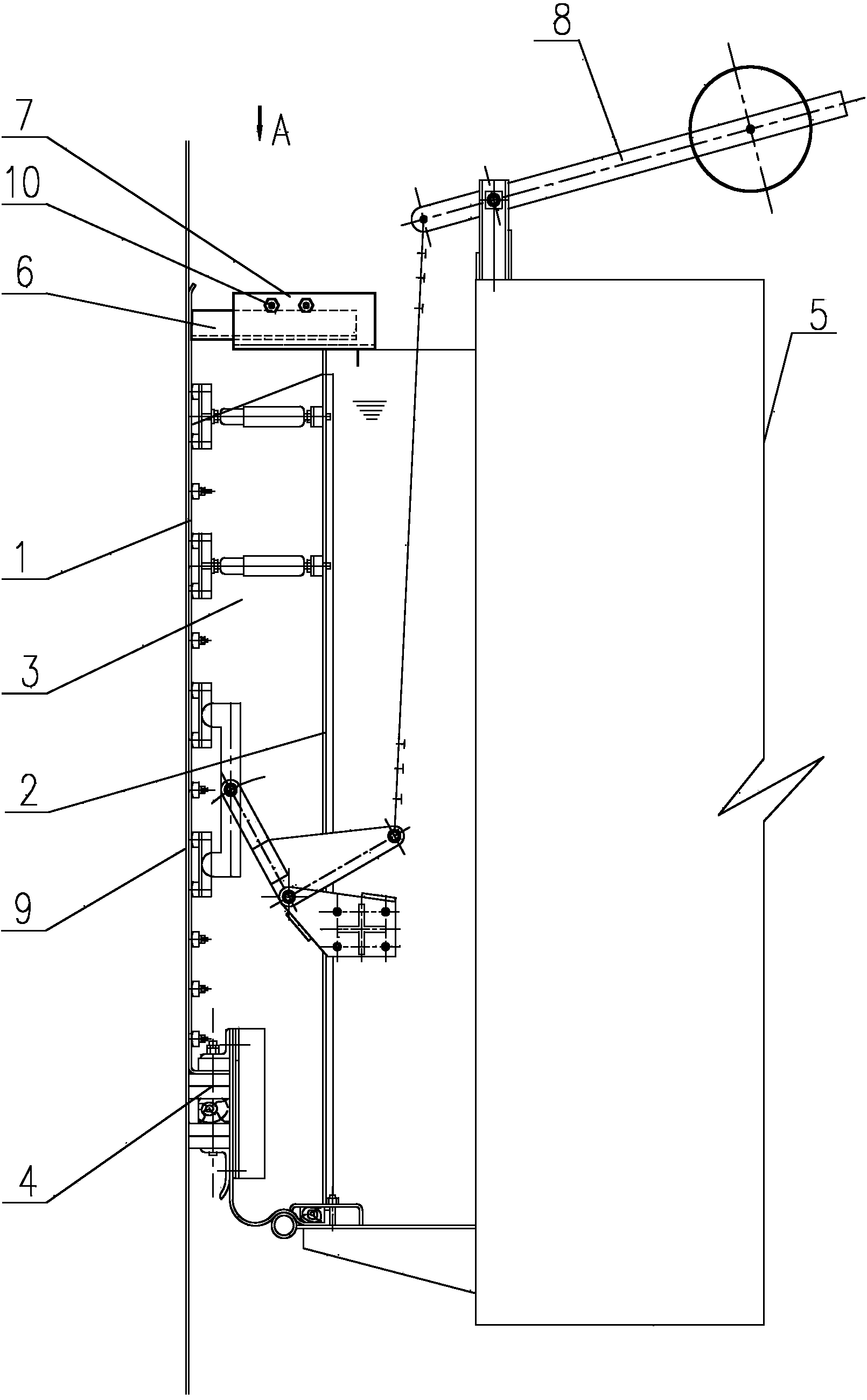

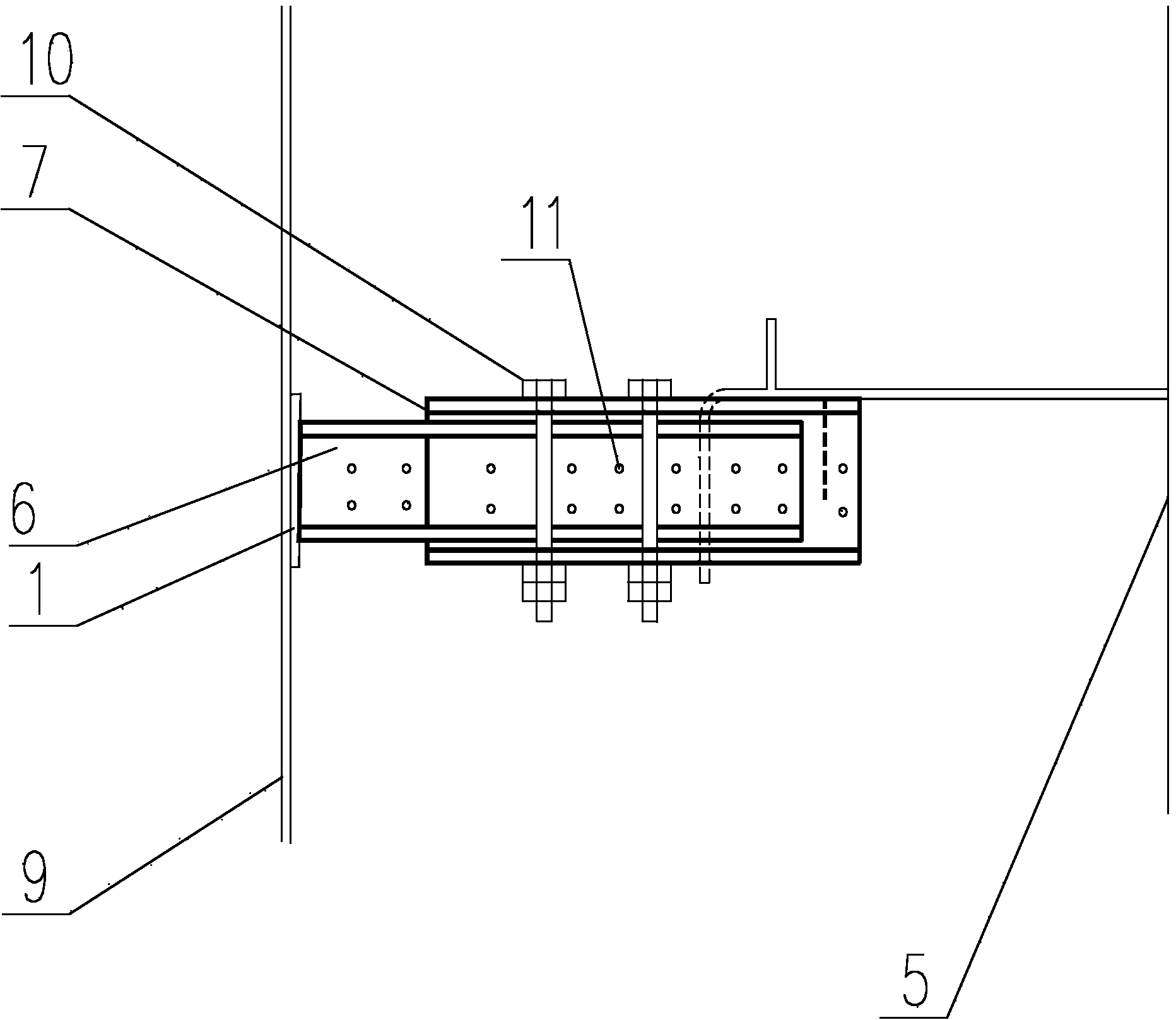

[0012] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0013] As shown in the figure, the gas tank piston oil ditch separation weir in this embodiment includes a weir slide plate 1, a weir partition plate 2, a weir canvas 3 and a seal clamping mechanism 4, and the lower end of the weir slide plate 1 is fixed on On the seal clamping mechanism 4, the upper end of the weir slide plate 1 is higher than the upper end of the weir partition plate 2, and the weir slide plate 1 is fixedly connected with a piston 5 at its position higher than the weir partition plate 2. The radially arranged support rods 6 are provided with a guide block 7 with a limit slot on the upper end of the weir partition 2, and the support rod 6 is inserted into the limit slot and slidably fits with the limit slot.

[0014] In this embodiment, the gas tank piston oil ditch separates the weir, which provides a supporting point for the upper en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com