Fertilizer cooling method and cooling device

A cooling method and a cooling device technology, which are applied to household refrigeration devices, lighting and heating equipment, household appliances, etc., can solve the problems of fertilizer product temperature rebound and rise, fertilizer particles are easy to absorb moisture, and generate waste gas, etc., so as to save energy consumption and cost, prevent moisture absorption, and improve quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

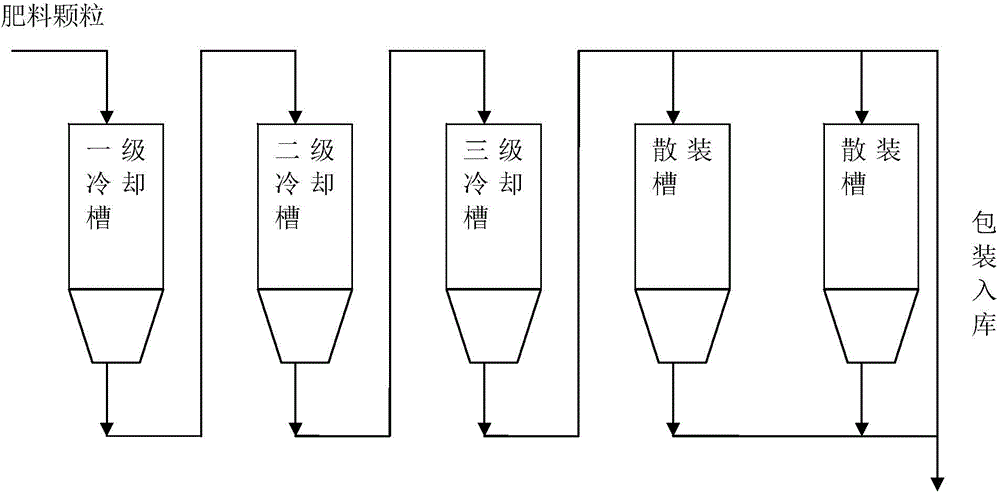

[0056] Such as figure 1 Shown, a kind of fertilizer cooling method comprises the steps:

[0057] (1) Anti-caking treatment is performed on the fertilizer granules coming out of the granulation device. The temperature of the fertilizer granules coming out of the granulation device is 75°C, and the temperature of the fertilizer granules after anti-caking treatment is 73°C;

[0058] (2) The fertilizer granules after anti-caking treatment are transported into the first-level cooling tank through the conveying equipment for the first cooling and cooling, and the temperature of the cooled fertilizer granules drops to 56°C;

[0059] (3) Carry out a warehouse dump: the fertilizer particles in the primary cooling tank are transported into the secondary cooling tank through the conveying equipment;

[0060] (4) The fertilizer granules are cooled for the second time in the secondary cooling tank, and the temperature of the cooled fertilizer granules drops to 46°C;

[0061] (5) Carrying...

Embodiment 2

[0066] A fertilizer cooling method, comprising the steps of:

[0067] (1) Anti-caking treatment is performed on the fertilizer granules coming out of the granulation device. The temperature of the fertilizer granules coming out of the granulation device is 60°C, and the temperature of the fertilizer granules after anti-caking treatment is 58°C;

[0068] (2) The fertilizer granules after anti-caking treatment are transported into the cooling tank through the conveying equipment for the first cooling and cooling, and the cooled fertilizer granules are cooled to 50°C;

[0069] (3) Carry out a warehouse dumping: through the conveying equipment, the fertilizer particles cooled for the first time are transported from the discharge port to the feed port of the cooling tank, and the fertilizer particles enter the cooling tank again;

[0070] (4) The fertilizer granules are cooled for the second time in the cooling tank, and the cooled fertilizer granules are cooled to 43°C;

[0071] ...

Embodiment 3

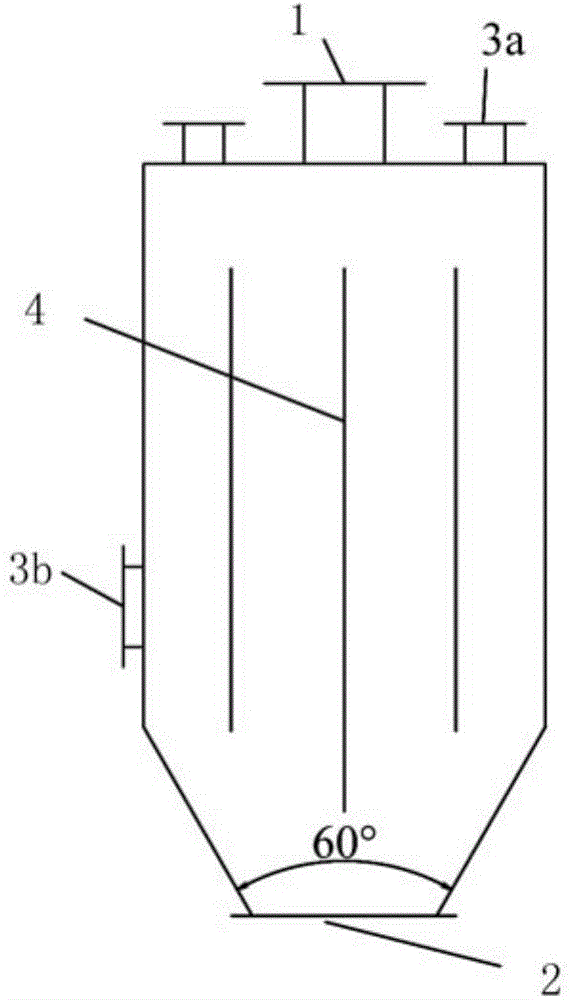

[0077] Such as figure 2 Shown, a kind of fertilizer cooling device, described device comprises cooling groove, and cooling groove top is provided with feeding port 1, and cooling groove bottom is provided with discharge port 2, and the bottom of described cooling groove is a cone, and the cone angle of cone is 60 °, the inside of the cooling tank is provided with 3 isolation plates 4, and the 3 isolation plates 4 are vertically arranged and parallel to each other. The 3 isolation plates 4 divide the inside of the cooling tank into 4 blanking channels in the horizontal direction. The distance between the top and the top of the cooling tank is 1 meter, the bottom extends to the middle of the cone, and the distance between the bottom and the inside of the cone is 1 meter.

[0078] The feed port 1 and the discharge port 2 of the cooling tank are respectively connected with the conveying pipes of the conveying equipment, so as to facilitate the conveying of the fertilizer particle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com