Thickness semi-compensated x-ray radiography inspection method of plug-in weld seam

A technology of weld thickness and detection method, applied in the direction of material analysis using radiation, can solve the problems of different imaging quality, low sensitivity of photographic inspection, and difference in transillumination thickness between the middle and end of the compensation block, so as to improve sensitivity, reduce Thin transillumination thickness, ensuring the effect of accuracy and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

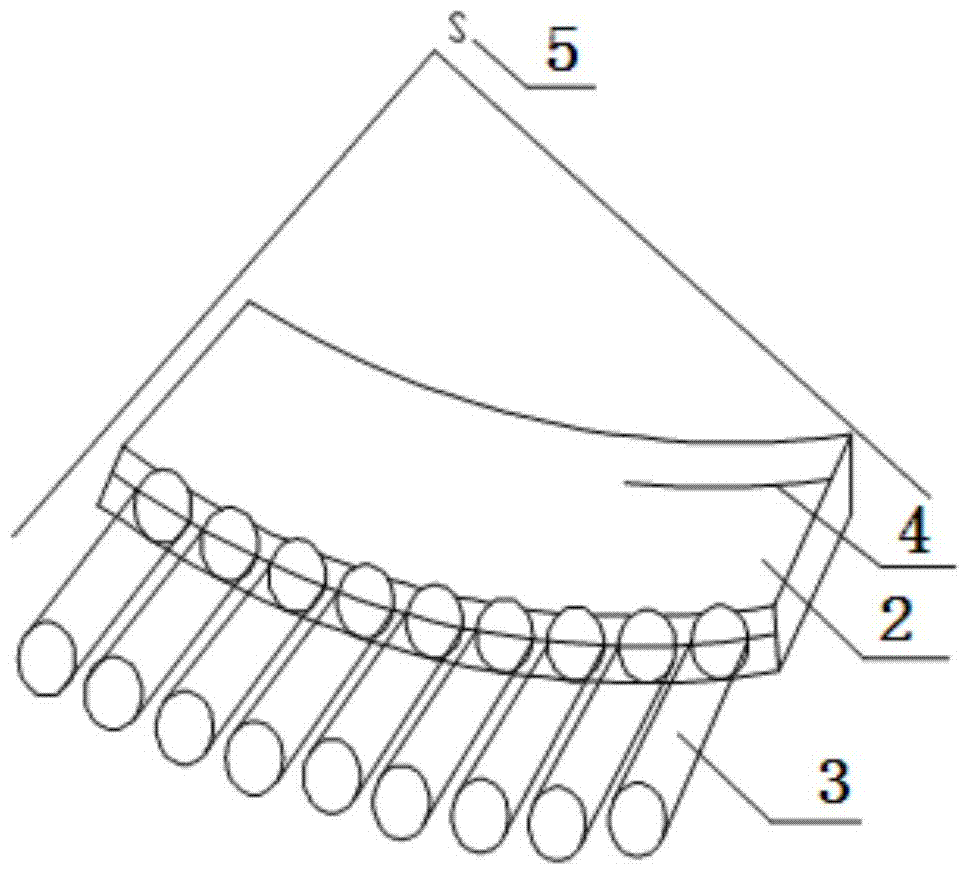

[0016] A half-compensated X-ray radiography detection method for the thickness of the socket-type cladding tube and end plug weld of the present invention will be further described in conjunction with the accompanying drawings and specific embodiments.

[0017] like figure 2 or image 3 As shown in the present invention, a half-compensated X-ray radiography detection method for the thickness of the plug-in cladding tube and the end plug weld seam comprises the following steps:

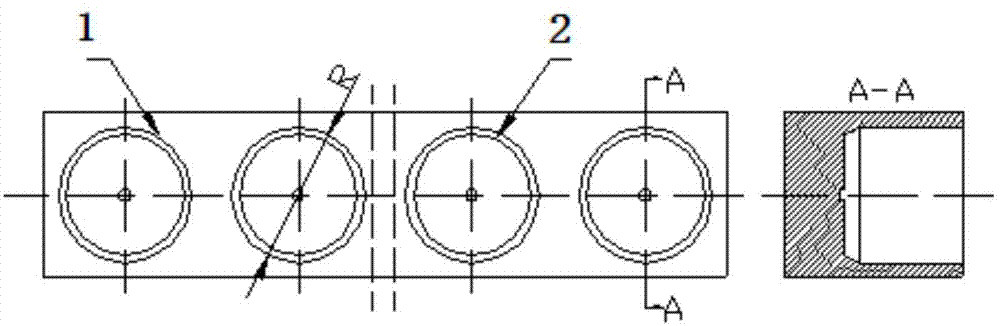

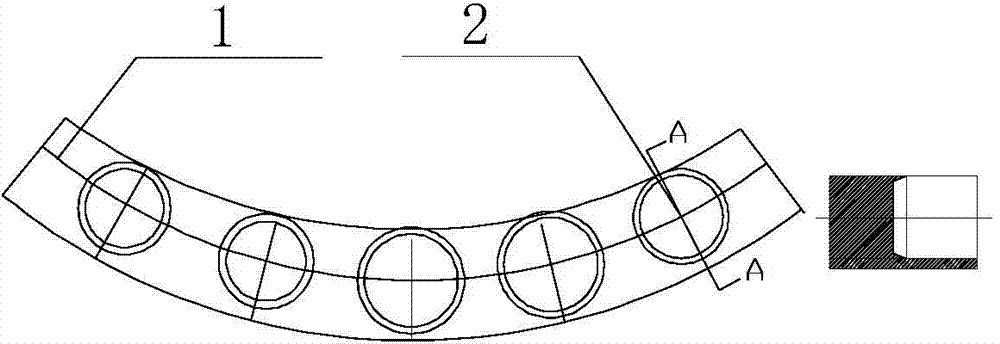

[0018] (a) if figure 2 As shown, a curved zirconium alloy plate with a length of 100 mm, a width of 50 mm, and a thickness of 8 mm is used as the compensation block 1, and the arc radius of the compensation block 1 is consistent with the focal length of the X-ray;

[0019] (b) if figure 2 As shown, 5 to 20 (for example: 5, 10 or 20) compensation holes 2 with equal diameters are processed on the compensation block 1, which is based on the outer diameter of the socket weld 3 and the thickness of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com