Large mining excavator and cable drum device thereof

A technology for cable drums and excavators, which is applied to the arrangement of paper reels/photosensitive drums, earth movers/excavators, transportation and packaging, etc., and can solve the problem of few maintenance windows and no lubrication of bearings Device, brush holder 36 damage and other problems, to achieve the effect of easy maintenance and meet the requirements of coaxiality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be noted that the embodiments described here are for illustration only, and are not intended to limit the present invention.

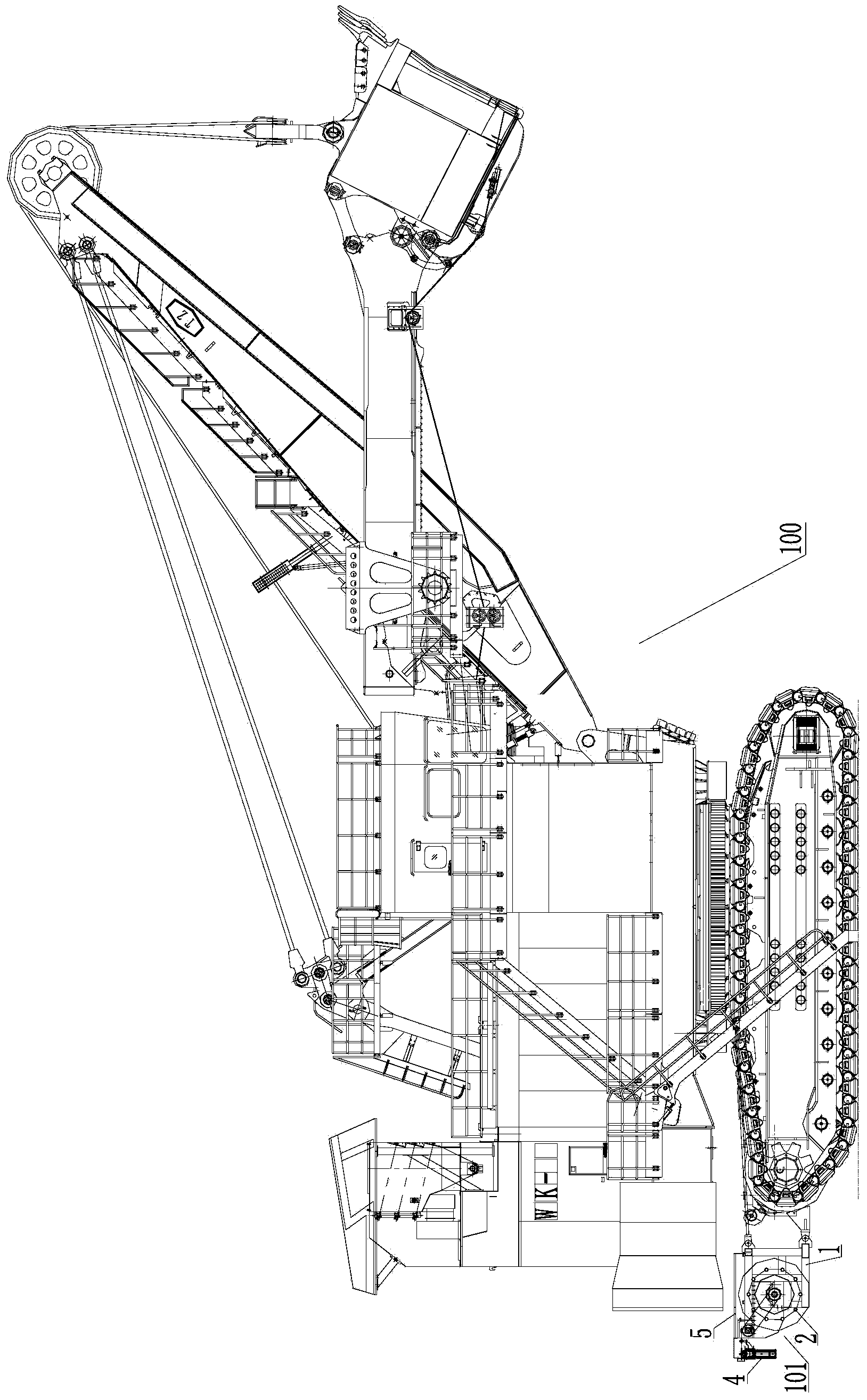

[0050] The cable reel device of the embodiment of the present invention can be used in the large mining excavator of the embodiment of the present invention; the large mining excavator of the embodiment of the present invention has the cable reel device of the embodiment of the present invention.

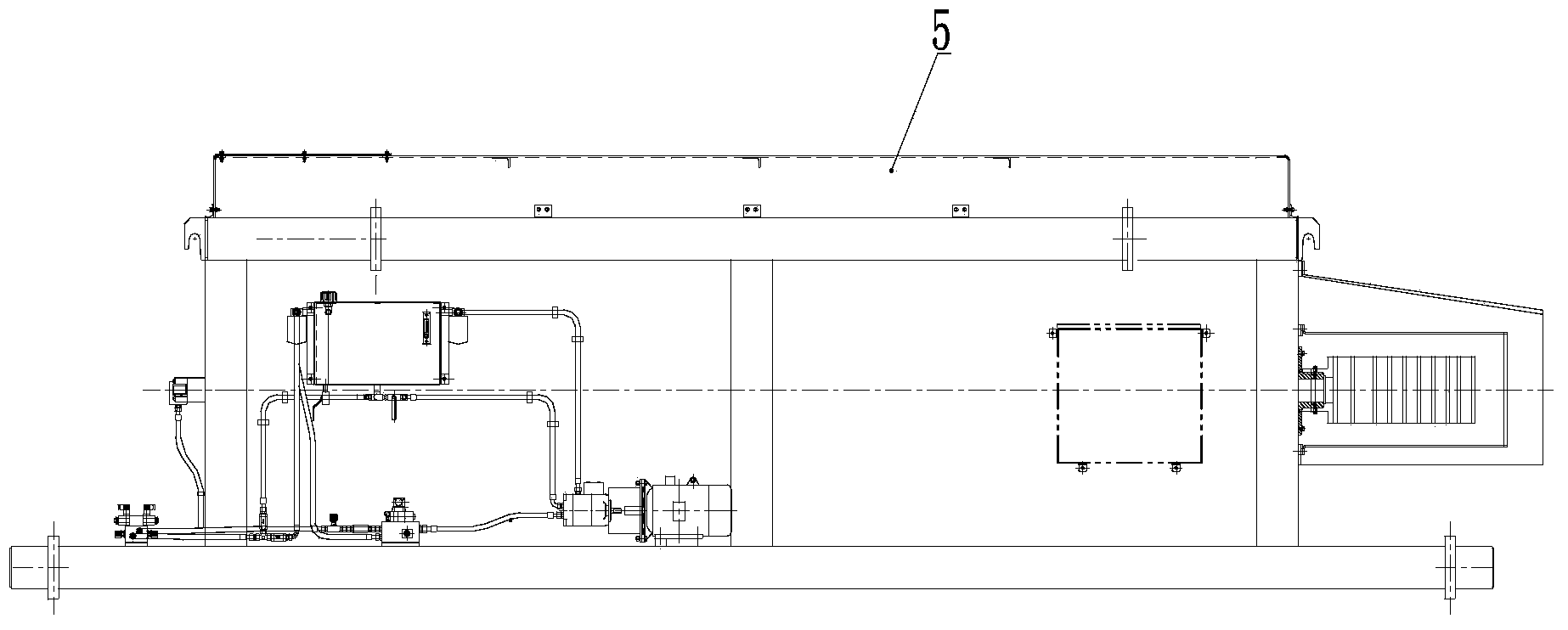

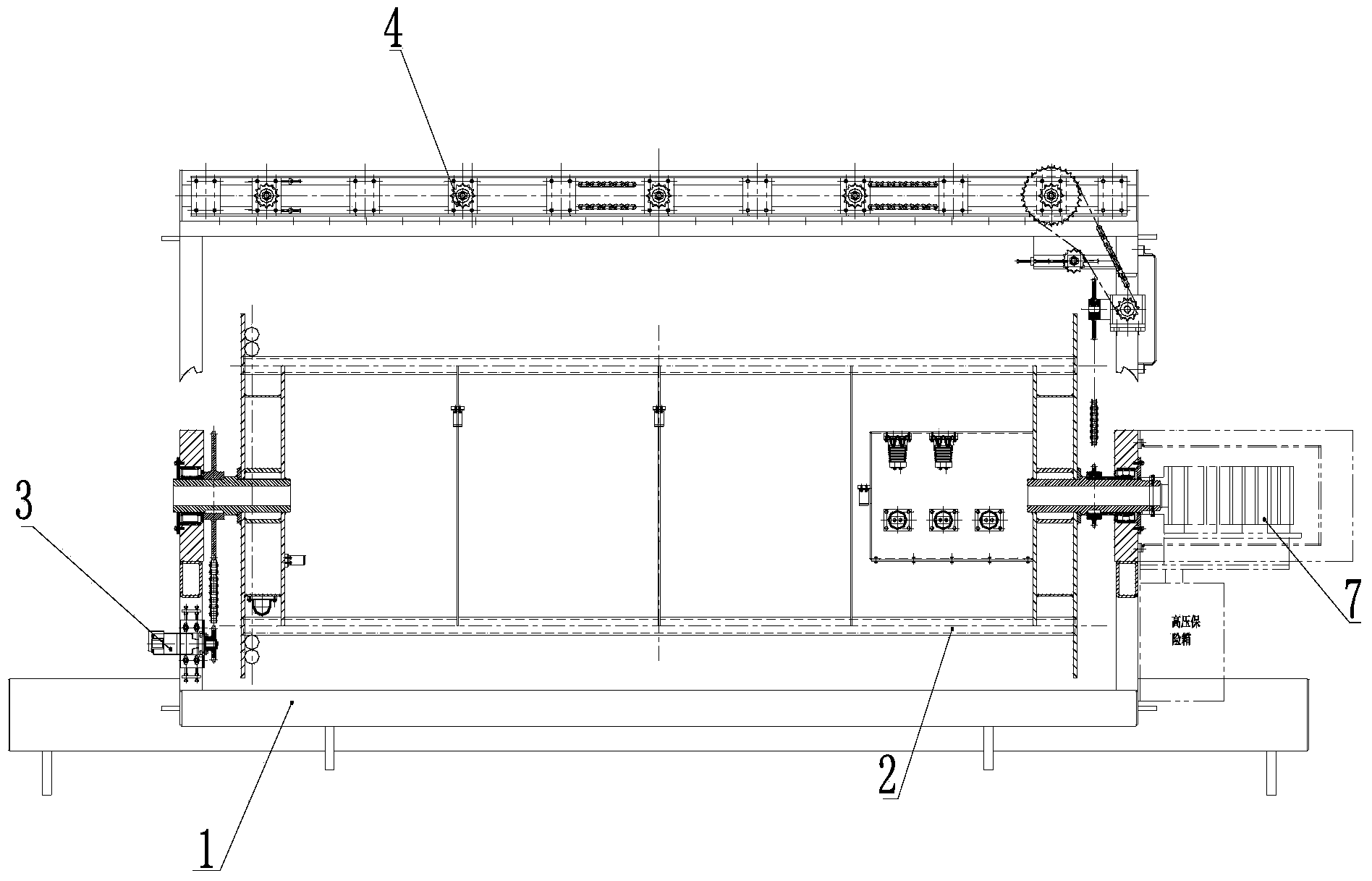

[0051] Such as Figure 10-Figure 12 As shown, the cable reel device of the embodiment of the present invention mainly includes: a bracket 1 , a reel 2 , a motor drive device 3 , a cable discharge mechanism 4 , a top cover 5 , a bearing lubricating device 6 and a high-voltage slip ring device 7 .

[0052] Such as Figure 13-Figure 15 As shown, the bracket 1 is used as the installation platform of the cable reel devi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com