Device for spraying dry ice snow

A technology of spraying device, dry ice and snow, applied in the direction of spraying device, liquid spraying device, abrasive feeding device, etc., can solve the problems of inability to achieve cleaning, reduced cleaning efficiency, poor cleaning efficiency, etc. And the effect of uniform spray

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] The cleaning test was performed using the dry ice and snow spray nozzle described in the above embodiment.

[0046] A glass substrate was prepared as a cleaning object, the ink adhered to the oil-based pen was removed by dry ice and snow cleaning, and the cleaning width of the removal was measured.

[0047] ·Test conditions

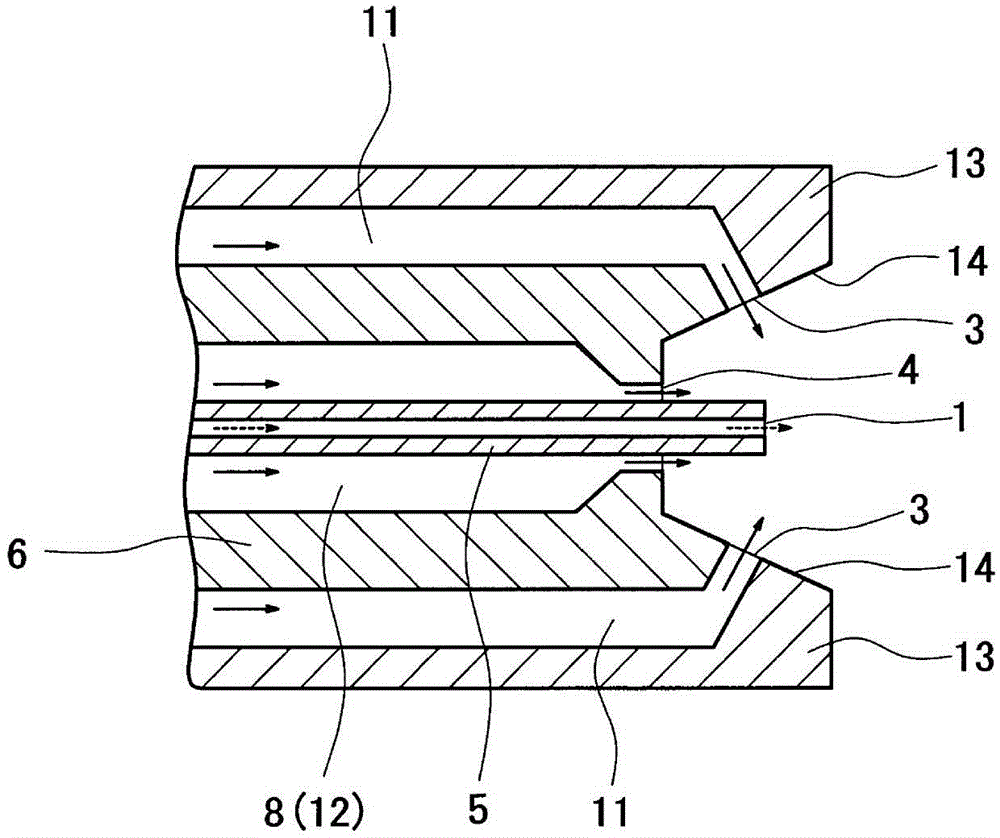

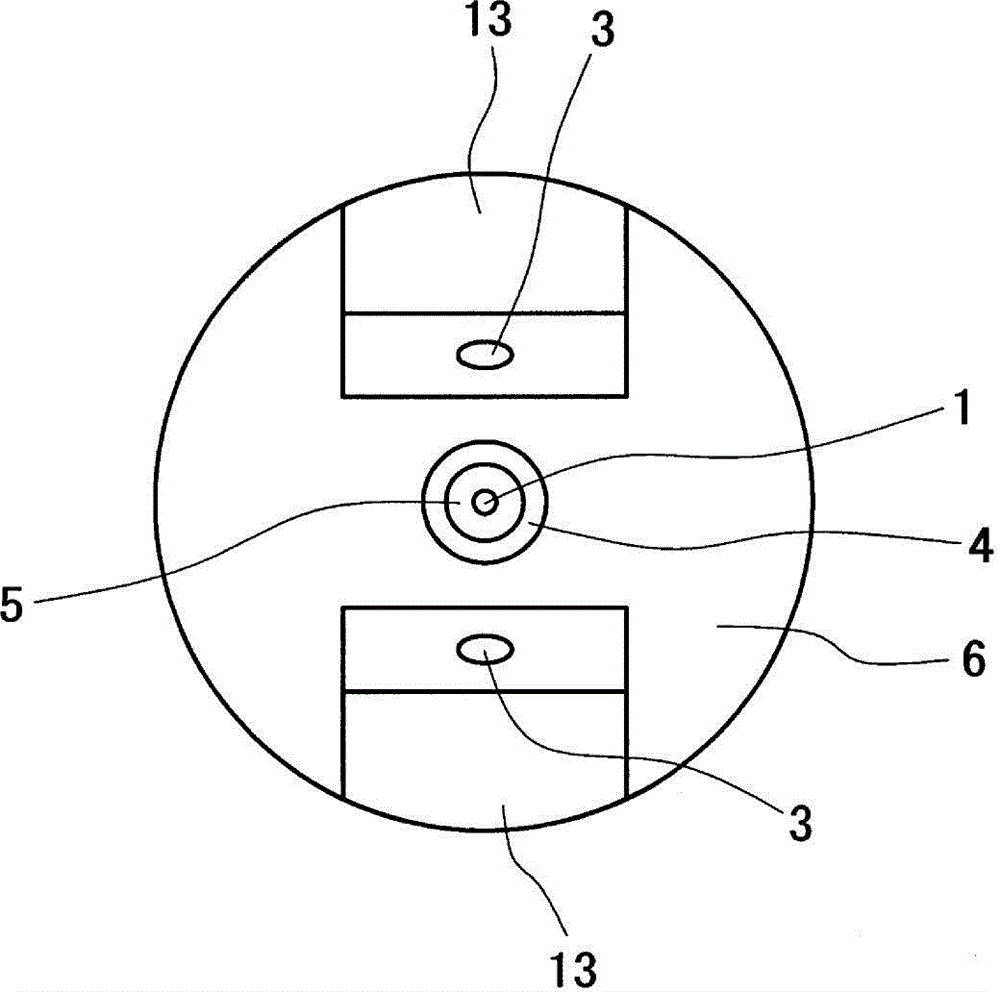

[0048] The angle of the inclined plane of the first rectifying gas outlet θ: 25°

[0049] The shape of the first rectifying gas outlet: φ1.6mm long hole structure

[0050] Outer diameter of dry ice and snow circulation pipe: φ1.6mm

[0051] The inner diameter of the second rectifying gas outlet: φ2.8mm

[0052] Rectified gas supply pressure: 0.45MPaG

[0053] Supply pressure of liquefied carbon dioxide gas: 7.0MPaG

[0054] Cleaning time: 120sec

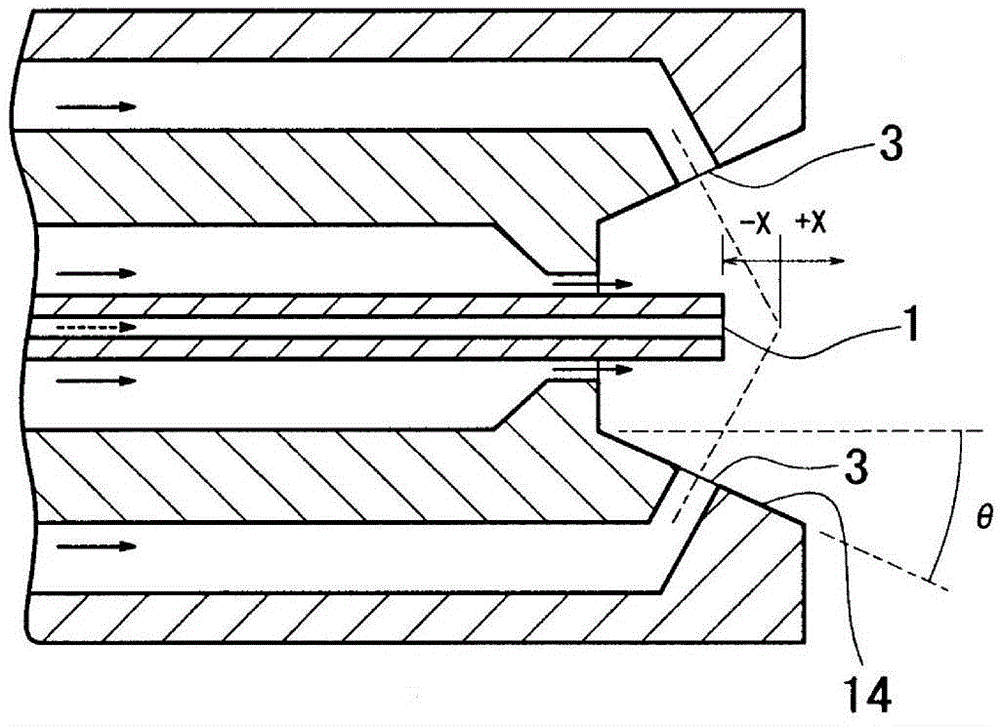

[0055] image 3 It is a diagram illustrating the dimensional relationship in the cleaning test.

[0056] The angle θ formed by the inclined surface 14 on which the first rectifying gas ejection port 3 is formed and the e...

Embodiment 2

[0064] The second rectifying gas ejection port 4 of the dry ice and snow spray nozzle implemented in Example 1 was protruded together with the dry ice and snow flow pipe 5, and the washing test was performed.

[0065] The positions of the second rectifying gas ejection port 4 and the dry ice and snow ejection port 1 are fixed by X=0 mm. In addition, the distance from the second rectifying gas ejection port 4 to the object to be cleaned was set to 21.5 mm.

[0066] As in Example 1, a glass substrate was prepared as an object to be cleaned, and the ink adhered to the oil-based pen was removed by dry ice and snow cleaning, and the cleaning width of the removal was measured.

[0067] ·Test conditions

[0068] The angle of the inclined plane of the first rectifying gas outlet θ: 25°

[0069] The shape of the first rectifying gas outlet: φ1.6mm long hole structure

[0070] Outer diameter of dry ice and snow circulation pipe: φ1.6mm

[0071] The inner diameter of the second rectifying gas outle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com