Short pipe supporting type jacket structure reaction kettle

A support type and reaction kettle technology, which is applied in the field of short tube support type jacket structure reaction kettle, can solve the problems of increasing the thickness of the inner cylinder shell, increasing the material cost, and the welding workload, etc., and achieving light weight and heat reduction. Produce, low-cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

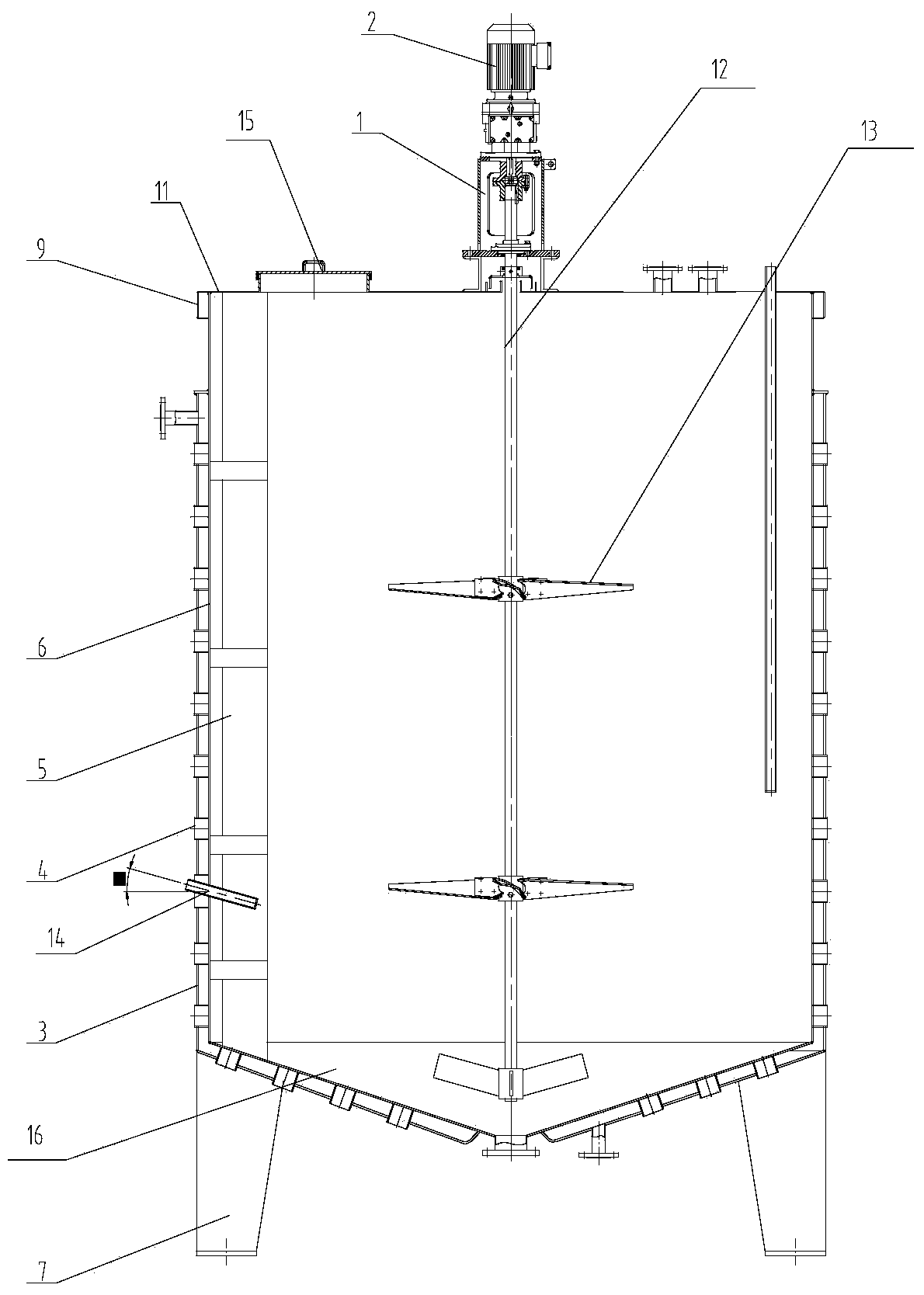

[0015] The present invention will be further described below in conjunction with the accompanying drawings.

[0016] like figure 1 The shown short tube supporting jacket structure reactor includes a reactor body 6, the lower end of the reactor body 6 is provided with a conical head 16, and the upper end of the conical head 16 is connected to a The supporting leg 7, the upper end of the reactor body 6 is provided with a flat end cover 11, the center of the flat end cover 11 is provided with a reduction unit 1, and the output end of the reduction unit 1 is connected with a A stirring shaft 12, a stirring blade 13 is arranged on the stirring shaft 12, a jacket 3 is arranged on the surface of the reactor body 6 and the conical head 16, and a through hole is arranged in a honeycomb shape on the jacket 3 , the reinforcing sleeve 4 connected to the surface of the reactor body is fixed in the through hole.

[0017] In the present invention, the lower end of the reinforcement sleeve ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com