Small-diameter-thick-ratio cold-drawn coiled-welded steel pipe and combined rotating die-drawn coiled pipe equipment

A technology of diameter-thickness ratio and steel pipe, which is applied in the field of small-diameter-thickness ratio cold drawn coiled welded steel pipe and combined rotating die drawing coiled pipe equipment, can solve the problems of high defect probability and high difficulty, and achieve the effect of reducing forming defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

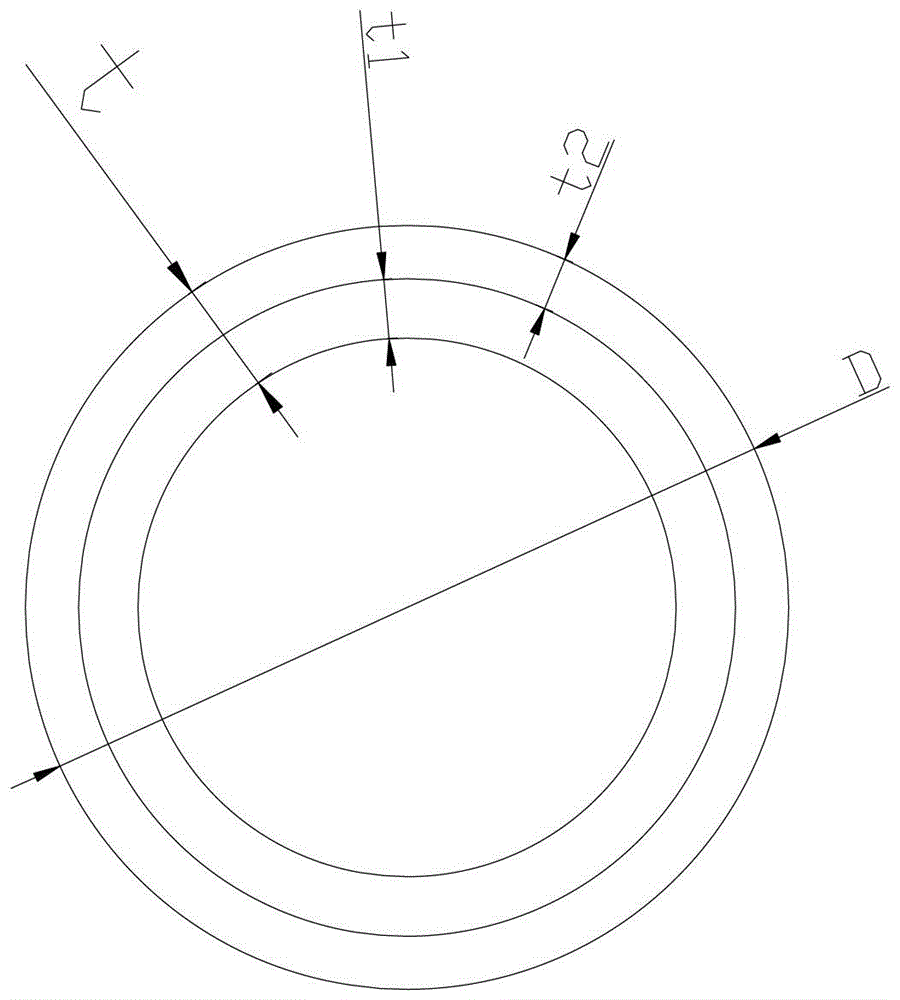

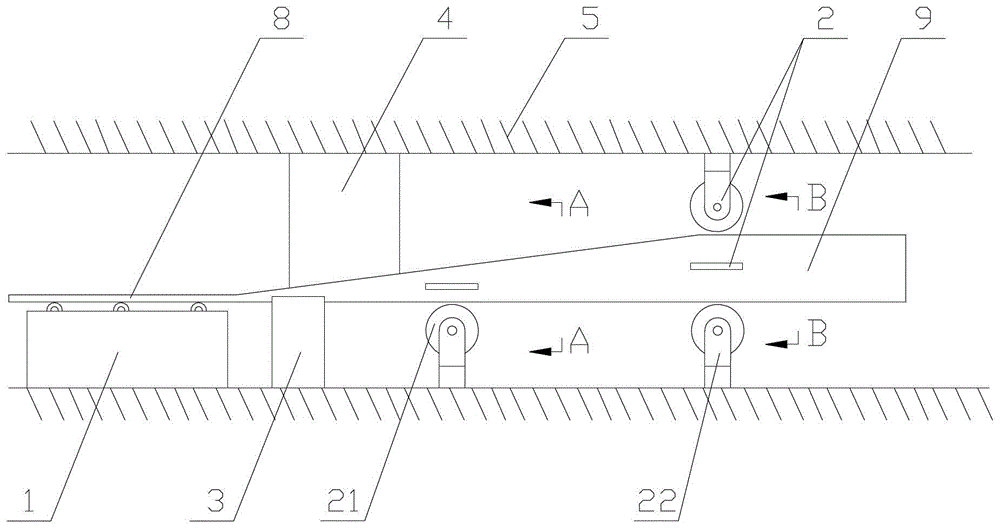

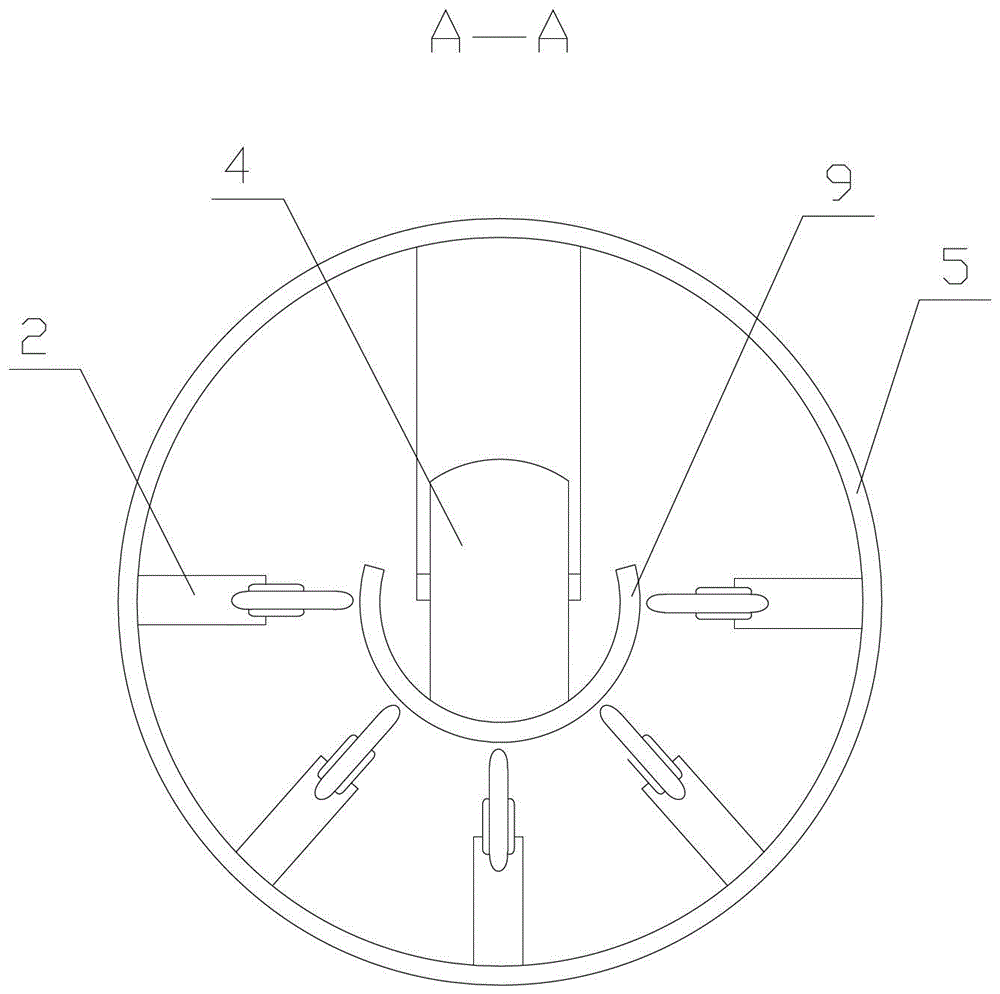

[0023] Small diameter thickness ratio cold drawn coil welded steel pipe, such as Figure 1 to Figure 4 As shown, the outer diameter of the steel pipe 9 is D, the wall thickness of the steel pipe 9 is t, the diameter-thickness ratio of the steel pipe 9 is D / t≤21, and the wall thickness of the steel pipe 9 after the steel plate 8 is rolled is t≥4mm. Steel pipe diameter-thickness ratio D / t can be 21, 20, 19, 18, 17, 16, 15, 14, and the thickness of t can be 4mm, 5mm, 6mm, 7mm, 8mm.

[0024] After the steel plate is rolled into the steel pipe, the seam of the steel pipe is arranged along the longitudinal direction of the steel pipe, and the seam of the steel pipe is connected by welding. After the steel plate is rolled into the steel pipe, the width direction of the steel plate is rolled into the circumferential direction of the steel pipe, and the length direction of the steel plate is rolled into the length direction of the steel pipe. The steel plate width required by the trad...

Embodiment 2

[0031] The difference between this embodiment and Embodiment 1 lies in that the diameter-thickness ratio of the steel pipe is D / t≤13, the thickness t of the steel plate is greater than 8mm, and the steel pipe is rolled by steel plate. Steel pipe diameter-thickness ratio D / t can be 13, 12, 11, 10, 9, 8, and the thickness of t can be 8mm, 9mm, 10mm, 11mm, 12mm. Such as figure 1 As stated, the diameter of the outer wall of the steel pipe in the present invention is D, and the wall thickness of the steel pipe is t, wherein the steel pipe wall thickness in the compression zone is t1, and the steel pipe wall thickness in the tension zone is t2, and t1+t2=t, t1≥t2 .

[0032] After the steel plate is rolled into the steel pipe, the seam of the steel pipe is arranged along the longitudinal direction of the steel pipe, and the seam of the steel pipe is connected by welding. After the steel plate is rolled into the steel pipe, the width direction of the steel plate is rolled into the c...

Embodiment 3

[0037] The difference between this embodiment and Embodiment 1 is that: the diameter-thickness ratio of the steel pipe is D / t≤7, the thickness t of the steel plate is greater than 12mm, and the steel pipe is rolled by steel plate. Steel pipe diameter-thickness ratio D / t can be 7, 6, 5, 4, and the thickness of t can be 13mm, 14mm, 15mm, 16mm, 17mm.

[0038] Such as figure 1 As shown, the diameter of the outer wall of the steel pipe in the present invention is D, and the wall thickness of the steel pipe is t, wherein the steel pipe wall thickness in the compression zone is t1, and the steel pipe wall thickness in the tension zone is t2, and t1+t2=t, t1≥t2 , and t1≥0.75t.

[0039] The invention is suitable for defect-free forming with diameter-thickness ratio D / t≤21, especially for defect-free forming with diameter-thickness ratio D / t≤14, suitable for forming steel plates with a thickness of more than 4 mm, and especially suitable for wall thickness of 16 mm The above cold-draw...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com