Forming die for inhibiting bending springback of plate and forming method of forming die

A technology for bending and springback, forming molds, applied in the direction of forming tools, manufacturing tools, metal processing equipment, etc., to achieve the effect of easy use, easy repair and maintenance, and easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

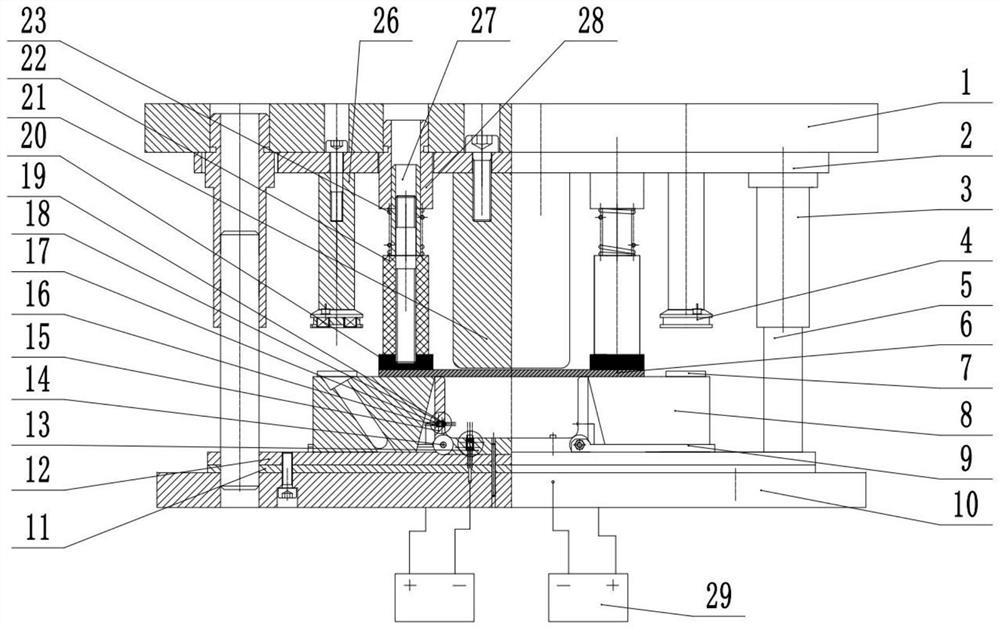

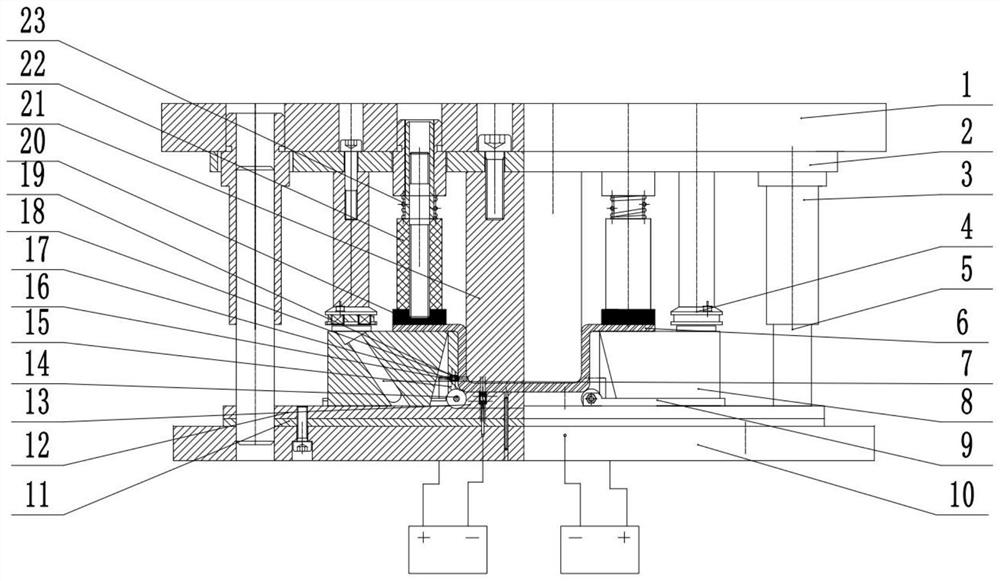

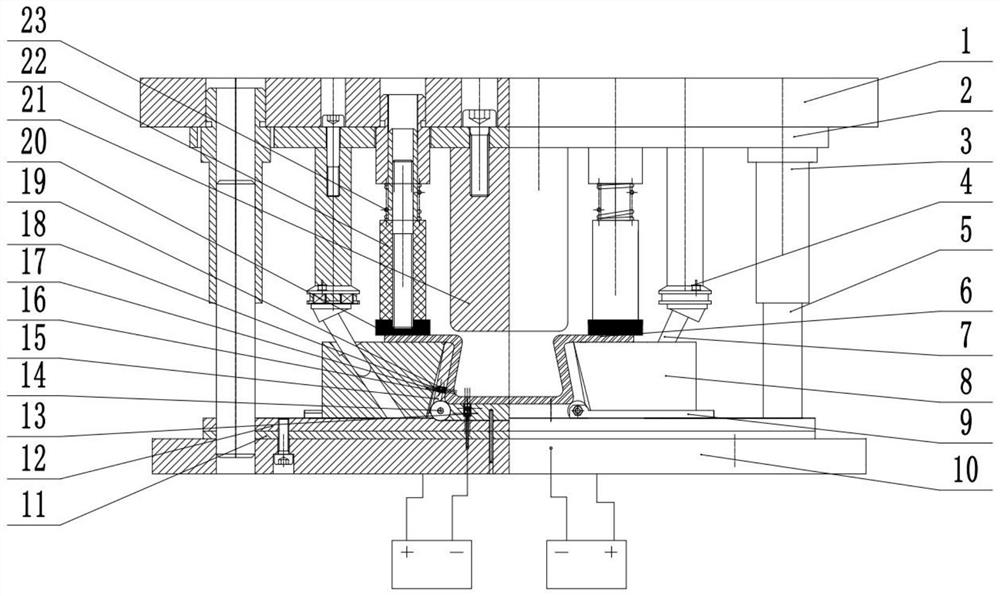

[0032] In order to detail the technical content, structural features, achieved goals and effects of the present invention, the following will be described in detail in conjunction with the accompanying drawings.

[0033] Forming dies used to suppress sheet bending springback, such as figure 1 and combine figure 2 with image 3As shown, it includes a punch assembly, a die assembly and a springback compensation assembly, the springback compensation assembly is located in the middle of the die assembly, the punch 21 in the punch assembly and the die bottom 13 of the springback compensation assembly Contact, the electrode 19 of the springback compensation component is respectively connected with the mounting end of the die bottom 13 of the springback compensation component and the die push plate 15, and through the mutual cooperation between the die and the punch 21, the adjustment of the sheet material 6 is completed. plastic processing. The springback compensation component ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com