A kind of composite shaft and its preparation method and application

A technology of composite materials and prepregs, applied in shafts and bearings, shafts, mechanical equipment, etc., can solve the problems of complex structure of marine drive shafts, failure to reach the entire shaft, complicated installation and maintenance, etc., to reduce molding defects, Lightweight, weight-optimized effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

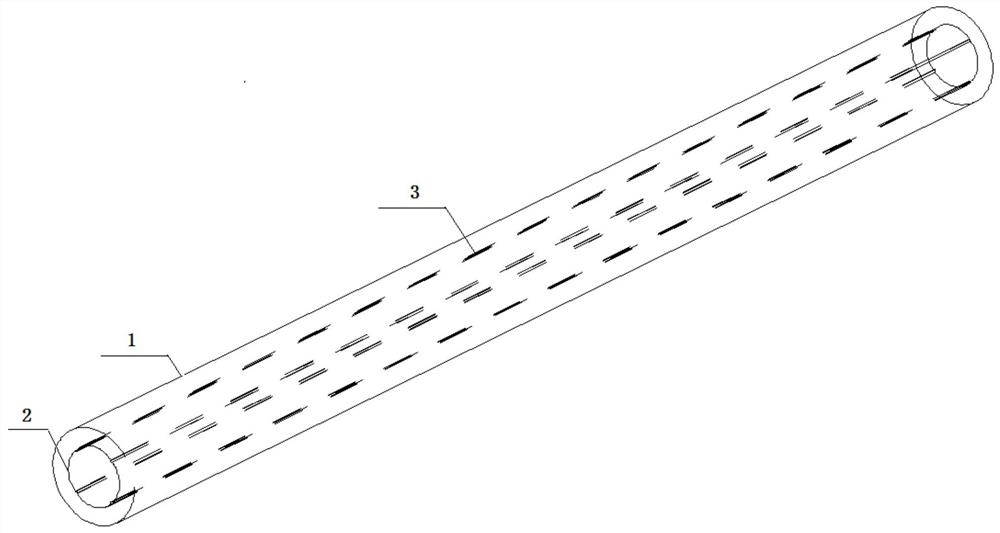

[0031] A kind of composite shaft of the present invention, its structure is as figure 1 As shown, it is a hollow shaft body, the outer surface 1 and the inner surface 2 of the hollow shaft body are both cylindrical surfaces, wherein ribs 3 are evenly distributed on the inner surface 2 of the hollow shaft body; Contains metal materials; the composite material shaft is obtained by internal expansion molding after the aramid fiber woven cloth is fully impregnated with TDE-85 epoxy resin.

[0032] The method for preparing a composite material shaft in this embodiment includes the following steps:

[0033] (1) Fully impregnating 1313 aramid fiber woven cloth in TDE-85 epoxy resin to obtain a prepreg;

[0034] (2) Wind the vacuum bag on the expansion shaft, then wrap the prepreg on the surface of the expansion shaft, wrap 350 layers, and then cover the release cloth;

[0035] (3) Assemble the cylindrical cavity and the expansion shaft wrapped with prepreg, turn the expansion shaft...

Embodiment 2

[0042] The composite shaft of this embodiment has the same structure as that of Embodiment 1.

[0043] The preparation method of the composite shaft of this embodiment includes the following steps:

[0044] (1) Fully impregnating 1313 aramid fiber woven cloth in TDE-85 epoxy resin to obtain a prepreg;

[0045] (2) Wrap the vacuum bag on the expansion shaft, then wrap the prepreg on the surface of the expansion shaft for 280 layers, and then cover the release cloth;

[0046] (3) Assemble the cylindrical cavity and the expansion shaft wrapped with prepreg, turn the expansion shaft arm, make the mandrel push the slider, pressurize radially from the inside to the outside, and the slider will expand to the maximum size. , seal the vacuum bag, insert the air guide tube, send it into the autoclave, connect the vacuum line of the autoclave, evacuate, heat up to 100°C, and then increase the pressure by 0.4MPa, keep the heat for 25 minutes, so that the epoxy resin Fully flow; then rai...

Embodiment 3

[0053] The structure of the composite material shaft in this embodiment is the same as that in Embodiment 1, except that the composite material shaft is obtained by inflating the carbon fiber fully impregnated with phenolic resin.

[0054] The preparation method of the composite shaft of this embodiment includes the following steps:

[0055] (1) T400 carbon fiber is fully impregnated in phenolic resin to obtain prepreg;

[0056] (2) Wrap the vacuum bag on the expansion shaft, then wrap the prepreg on the surface of the expansion shaft for 270 layers, and then cover the release cloth;

[0057] (3) Assemble the cylindrical cavity and the expansion shaft wrapped with prepreg, turn the expansion shaft arm, make the mandrel push the slider, pressurize radially from the inside to the outside, and the slider will expand to the maximum size. , seal the vacuum bag, insert the air guide tube, send it into the autoclave, connect the vacuum line of the autoclave, evacuate, heat up to 100...

PUM

| Property | Measurement | Unit |

|---|---|---|

| torque | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com