Plate splicing machine

A jigsaw machine and backing plate technology, applied in metal processing equipment, auxiliary welding equipment, welding equipment, etc., can solve problems affecting welding quality, affecting normal welding of welding guns, and compacting welding parts, so as to shorten the positioning time, Improve welding quality and efficiency, and reduce manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

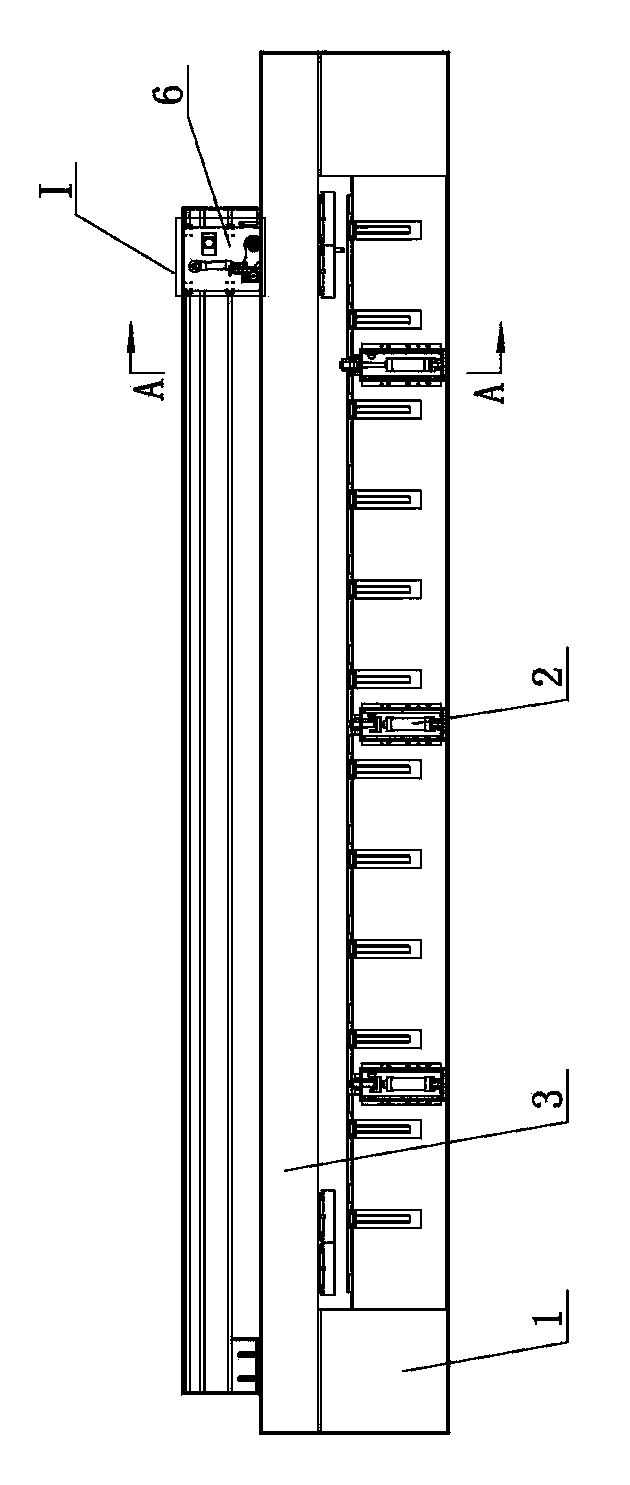

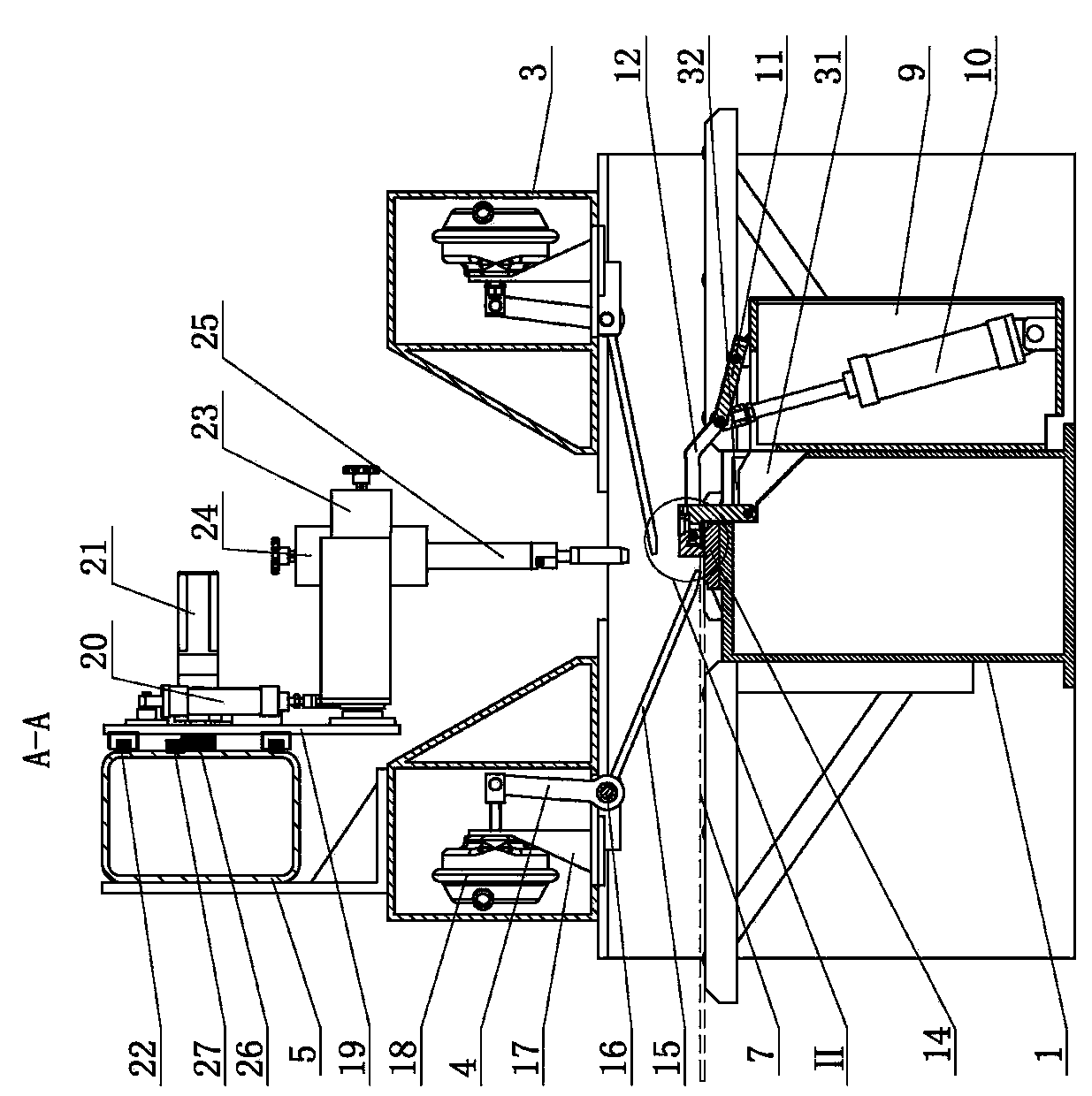

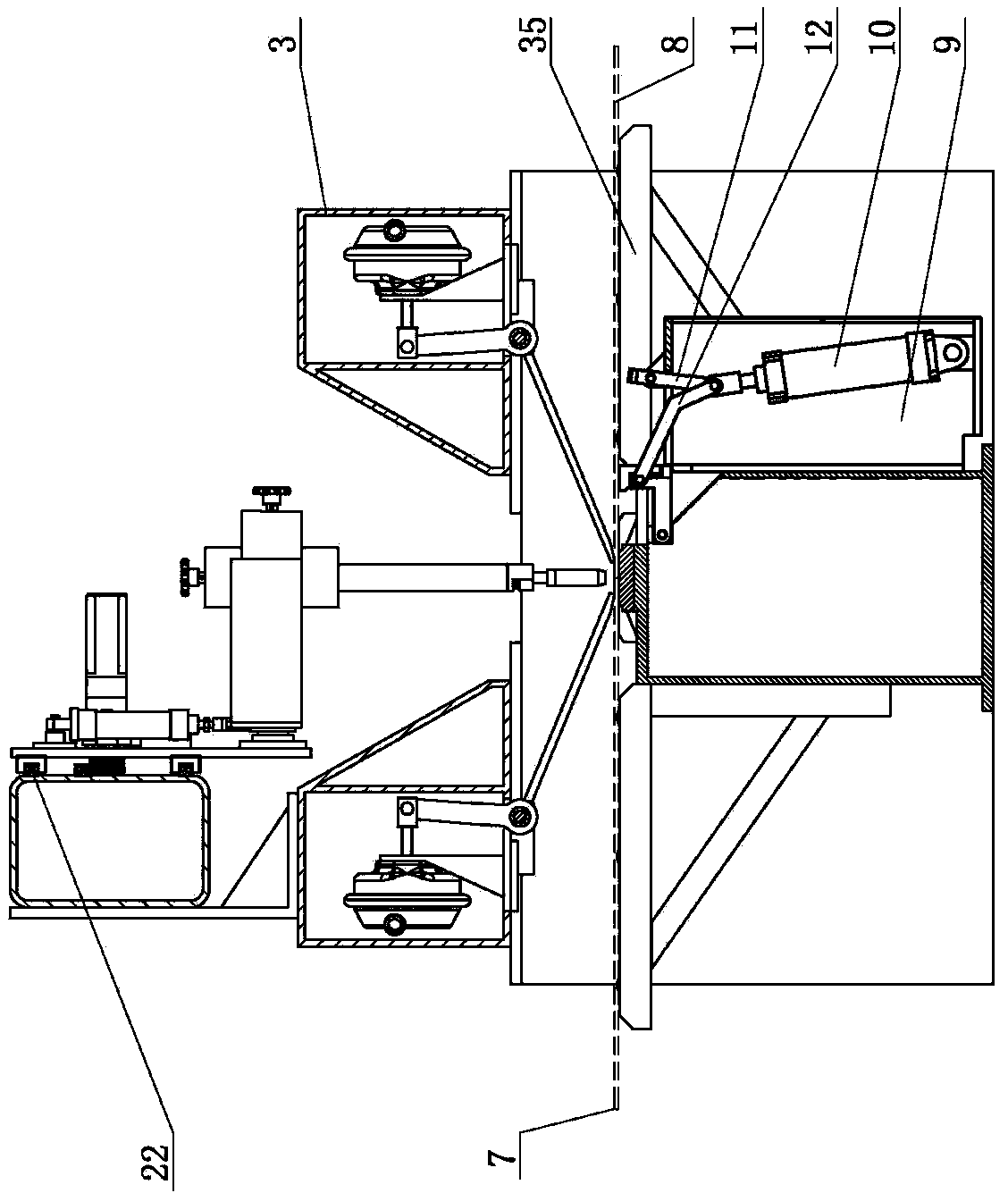

[0009] Such as figure 1 As shown, the jigsaw machine of the present invention includes a base (1). Such as figure 2 As shown, the base (1) is provided with a molded backing plate (14). The forming backing plate (14) can be integrated with the base (1), but the manufacturing of the integrated processing is difficult, and the forming backing plate (14) is not easy to replace. Two sets of fixing mechanisms are installed on the base (1). The two sets of fixing mechanisms are respectively located on both sides of the forming backing plate (14), and higher than the forming backing plate (14), can use the gravity of the pressure plate (15) of the fixing mechanism to assist in pressing the sheet material, so as to reduce the pressure of the fixing mechanism Tight load. Mount the welding gun moving mechanism on the base (1) or the fixed mechanism. The welding gun assembly is installed on the moving parts of the welding gun moving mechanism. Such as figure 1 As shown, the welding gu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com