Driving device of platen automatic die cutting hot stamping machine moving platform

A driving device, flat automatic technology, applied in printing presses, rotary printing machines, printing, etc., can solve the problems of toggle mechanism load concentration, high material strength requirements, affecting equipment performance stability and service life, etc., to achieve high The effect of quality bronzing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

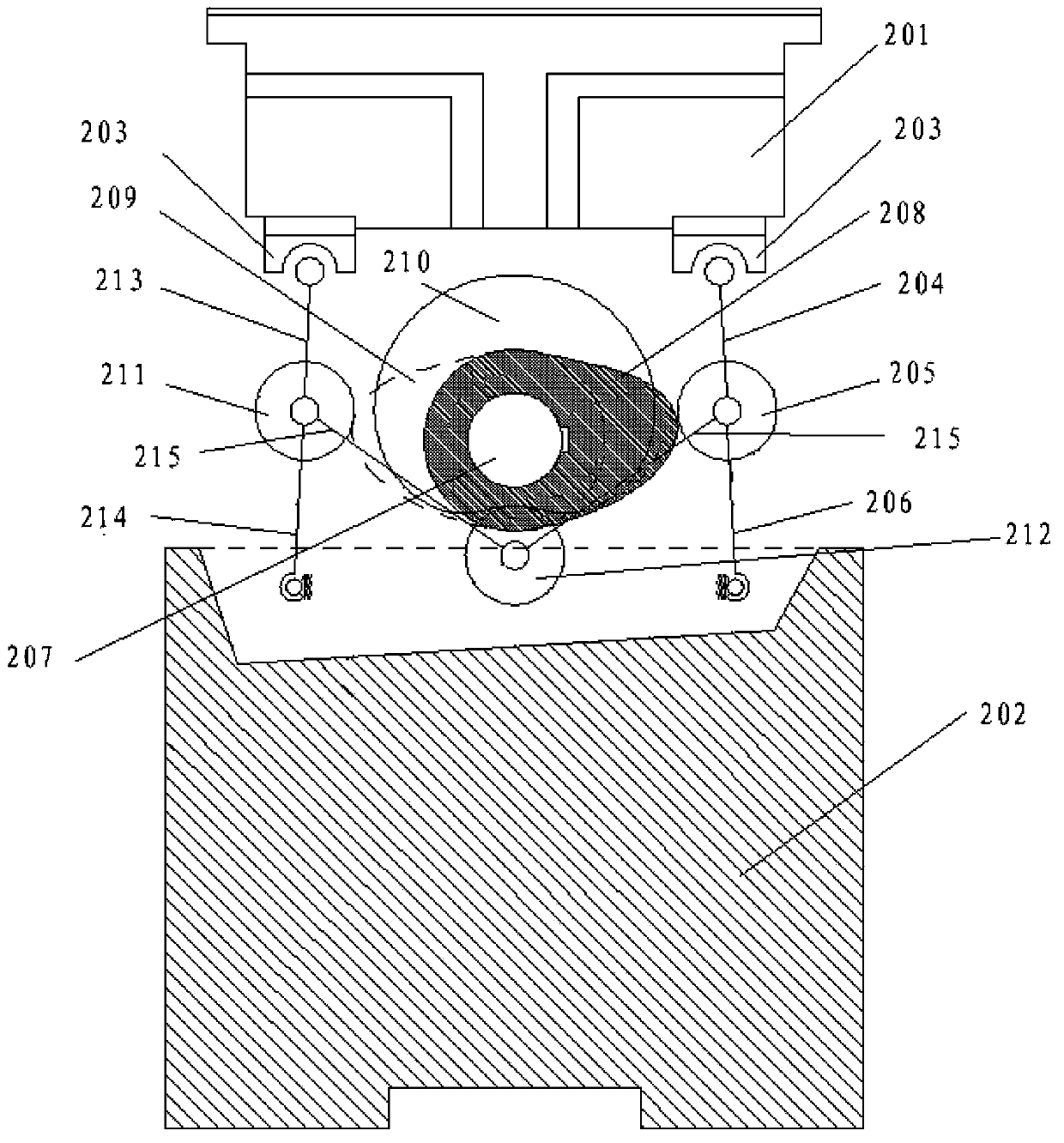

[0026] refer to figure 2 As shown, it is a structural schematic diagram of a flat-pressing automatic die-cutting bronzing motorized platform driving device according to an embodiment of the present invention. The flat-pressing flat automatic die-cutting and bronzing motorized platform driving device is arranged between the moving platform 201 and the base 202, The flat pressing flat automatic die-cutting bronzing motorized platform driving device includes a drive shaft 207, a first cam 208, a second cam 209, a first driven roller 205, a second driven roller 211, a third driven roller 212, a An upper toggle 204 , a second upper toggle 213 , a first lower toggle 206 and a second lower toggle 214 . Wherein, the driving sha...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap