Preparation method for low molecular weight polyester used for manufacturing multi-component fiber

A multi-component fiber, low molecular weight technology, applied in the field of low molecular weight polyester preparation, can solve the problem of high price of pure PTT fiber, achieve the effects of good spinnability, high bulkiness and good industrial application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~9

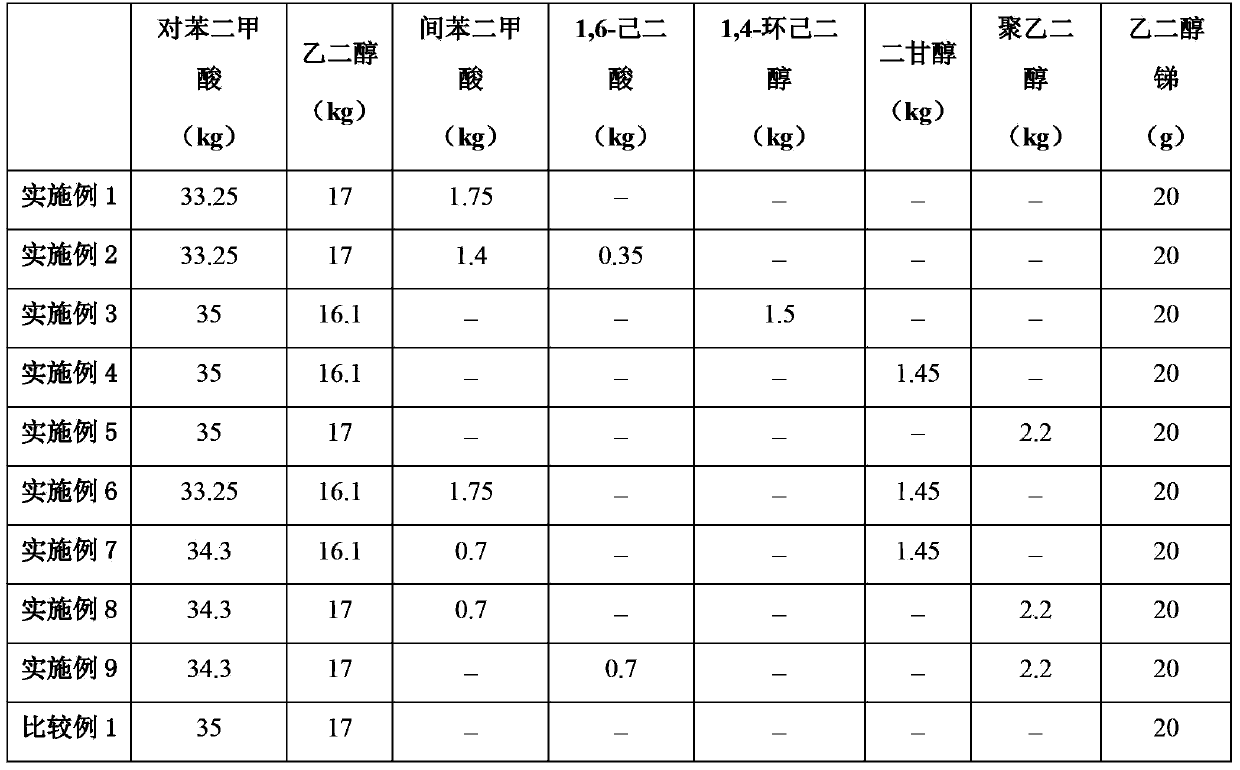

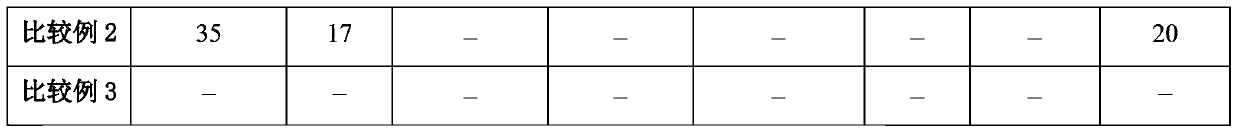

[0024] 1) Use terephthalic acid, ethylene glycol, monomers with dicarboxylic reactive functional groups other than terephthalic acid, and monomers with dihydroxy reactive functional groups other than ethylene glycol as reaction raw materials (raw material ratio See Table 1), carry out the esterification reaction at a temperature of 250°C, the esterification pressure is 30kPa, remove the generated water during the reaction process, and when the reaction esterification rate reaches 95%, the esterification is complete;

[0025] 2) In the presence of a polycondensation catalyst, the intermediate of the esterification product is further esterified and precondensed at a reaction temperature of 260°C under the condition of -2KPa to obtain a polyester oligomer with a certain degree of polymerization, and the reaction time is 2 hours ; Then under the vacuum condition of -0.1KPa, the polycondensation reaction temperature is 280 ℃, and the reaction time is 2 hours, and the low molecular w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com