Multi-angle spraying water coal slurry gasification device

A gasification device, a coal-water slurry technology, which is applied in the gasification of granular/powdered fuel, the production of combustible gas, and the liquid carbon-containing fuel, etc. It can improve the reaction efficiency, increase the amount of coal input, and achieve uniform atomization effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

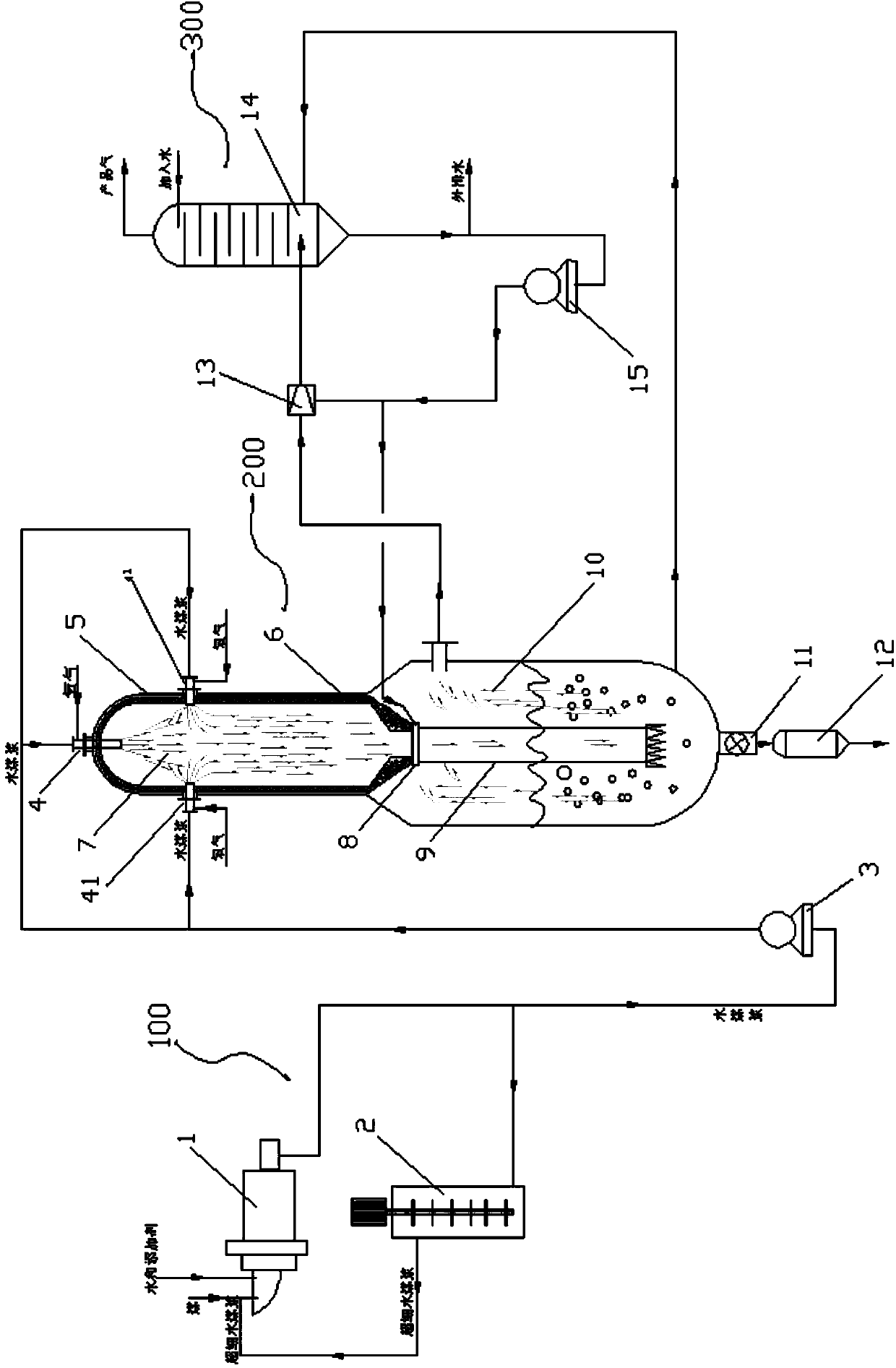

[0016] like figure 1 As shown, the present invention includes a coal water slurry preparation mechanism 100 , a gasification mechanism 200 and a washing mechanism 300 .

[0017] The coal water slurry preparation mechanism 100 includes a coarse grinder 1 , a fine grinder 2 and a coal slurry pump 3 . The discharge port of the coarse mill 1 is divided into two routes, one route is connected with the feed port of the fine mill 2, the other route is connected with the coal slurry pump 3, and the discharge port of the fine mill 2 is connected with the feed port of the coarse mill 1. The feed port is connected. In this embodiment, the coal-water slurry preparation mechanism 100 adopts the method of preparing high-concentration coal-water slurry with low-rank coal to produce high-concentration coal-water slurry whose coal particle mass accounts for more tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com