Device for evenly tensioning anchor cable

A tensioning device and uniform technology, applied in foundation structure engineering, sheet pile walls, buildings, etc., can solve the safety hazards of prestressed anchor cables in stable service, single steel strand breaking and wire drawing, and anchor cable anchoring force reduction Steel strands and other issues, to achieve the effect of simple structure, perfect control, and improved tensioning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

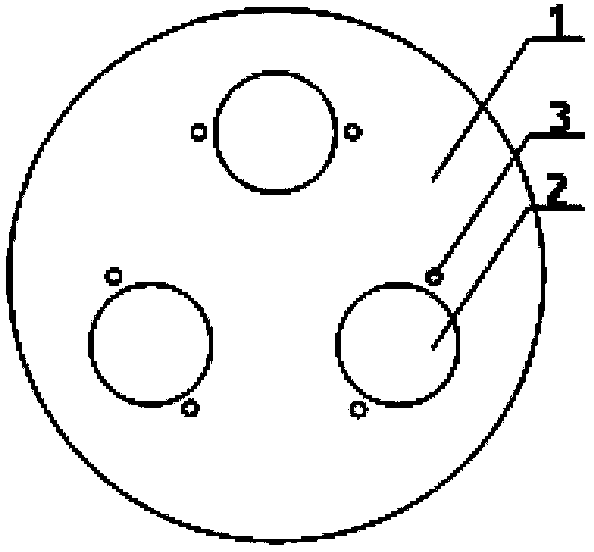

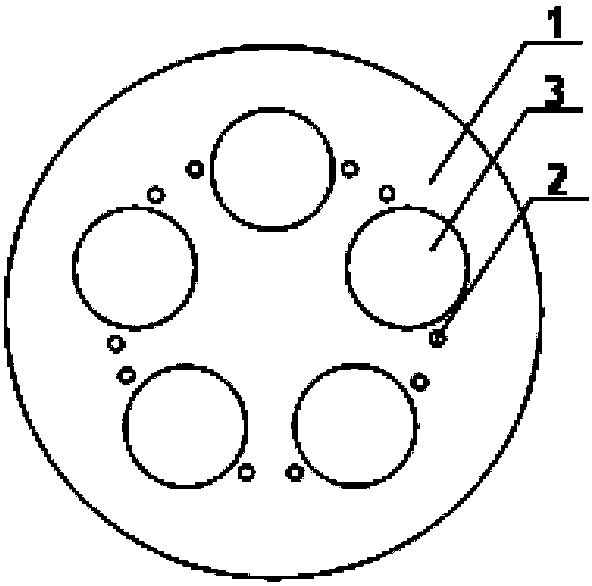

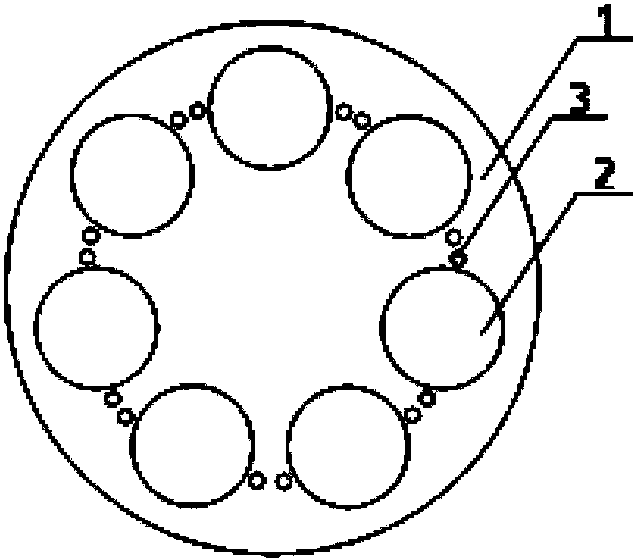

[0031] The anchor cable uniform tensioning device in the present invention comprises two oil cylinder position control plates 1 and a plurality of small tension oil cylinders, and the two oil cylinder position control plates 1 are arranged at both ends of the tension oil cylinders.

[0032] The oil cylinder position control plate 1 is a circular plate, and can also be various regular polygons, such as a square, a regular pentagon, etc., and at least two position control stretching areas are equidistantly arranged on the periphery of the oil cylinder position control plate 1 , each position control stretching area corresponds to a tension cylinder, and each is provided with a steel strand hole 2 and two position control plate screw holes 3 around the steel strand hole 2, thus, according to the anchor cable middle steel The number of twisted wires, choose a control board with an appropriate number of control stretch zones, such as Figure 1-3 Shown are the schematic diagrams of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com