Airtight connection structure for oil well pipe

A connection structure and air-sealing technology, applied in drill pipes, casings, drilling equipment, etc., can solve the problem of no sealing surface, and achieve the effects of uniform force, increased reliability, and improved tensile safety factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

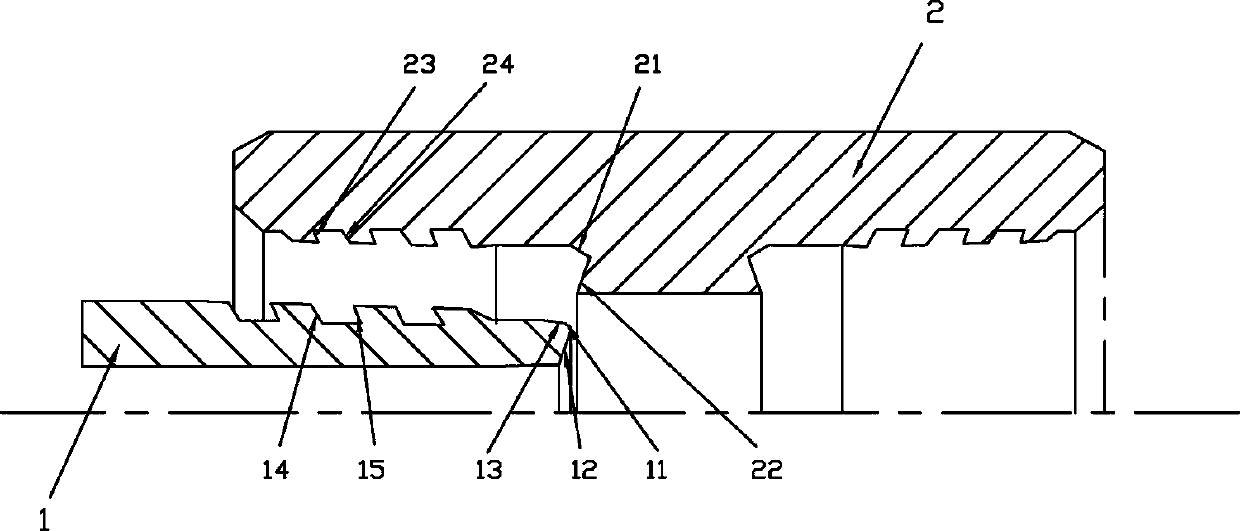

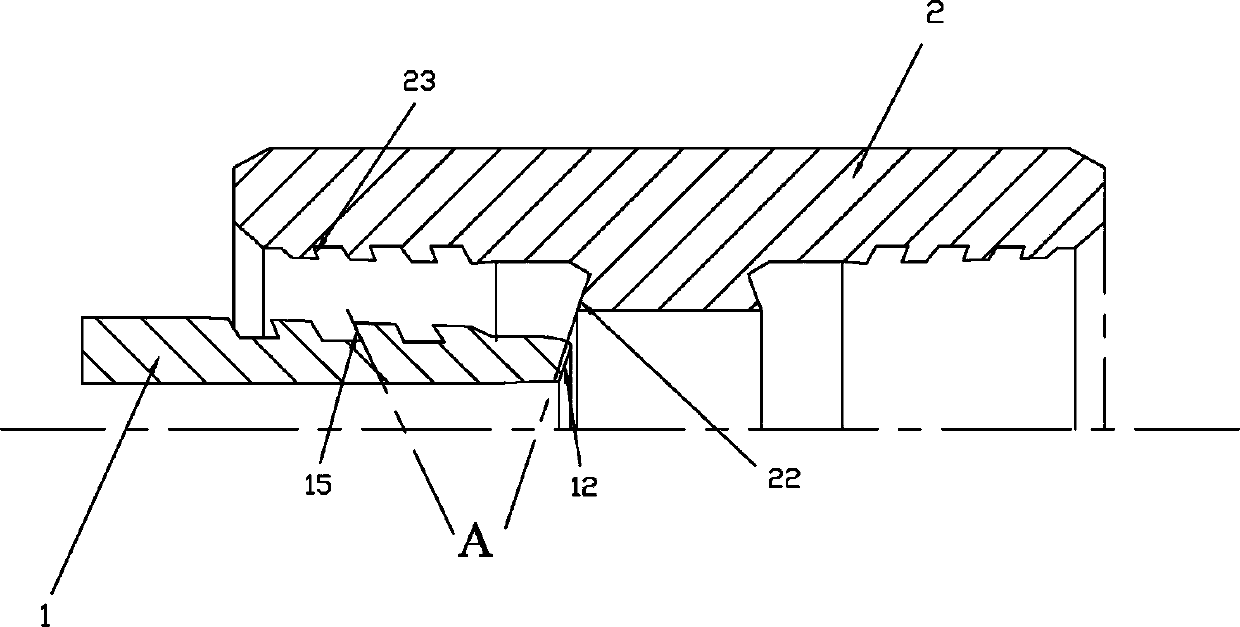

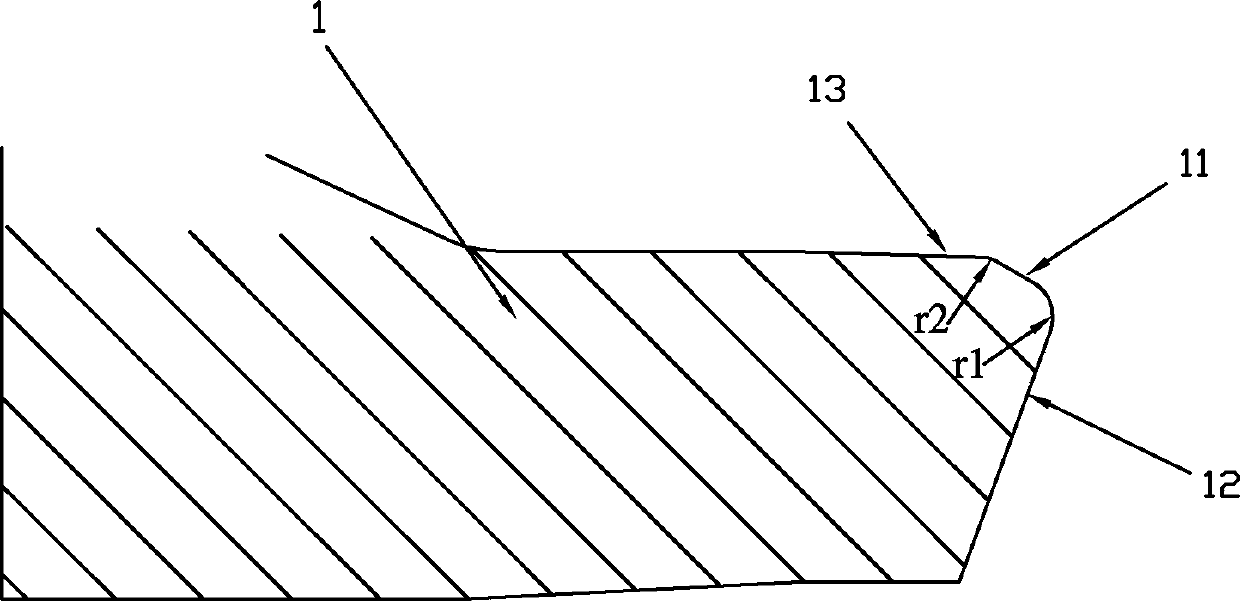

[0041] see Figure 1 ~ Figure 4 , the gas-tight connection structure for oil well pipes of the present invention, which includes a thread structure and a sealing surface structure matched between the pipe body 1 and the coupling 2; the thread of the pipe body 1 is an external thread and a partial trapezoidal thread; The thread of the coupling 2 described above is an internal thread and a partial trapezoidal thread; the sealing surface of the pipe body 1 includes the outer main sealing surface 11 on the end side of the pipe body, the second outer main sealing surface 11 connected to the side of the outer main sealing surface 11 and located on the end surface. An outer auxiliary sealing surface 12, a second outer auxiliary sealing surface 13 connected to the other side of the outer main sealing surface 11; the sealing surface of the collar 2 includes an inner main sealing surface 21 corresponding to the outer main sealing surface 11 of the pipe, a corresponding The inner auxilia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com