Returning spring adjustment device and method for wave power system

A power system and return spring technology, which is applied to engine components, machines/engines, ocean energy power generation, etc., can solve the problems of return spring overwork, change of working range, damage, etc., so as to improve the life of return spring and avoid metal fatigue Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

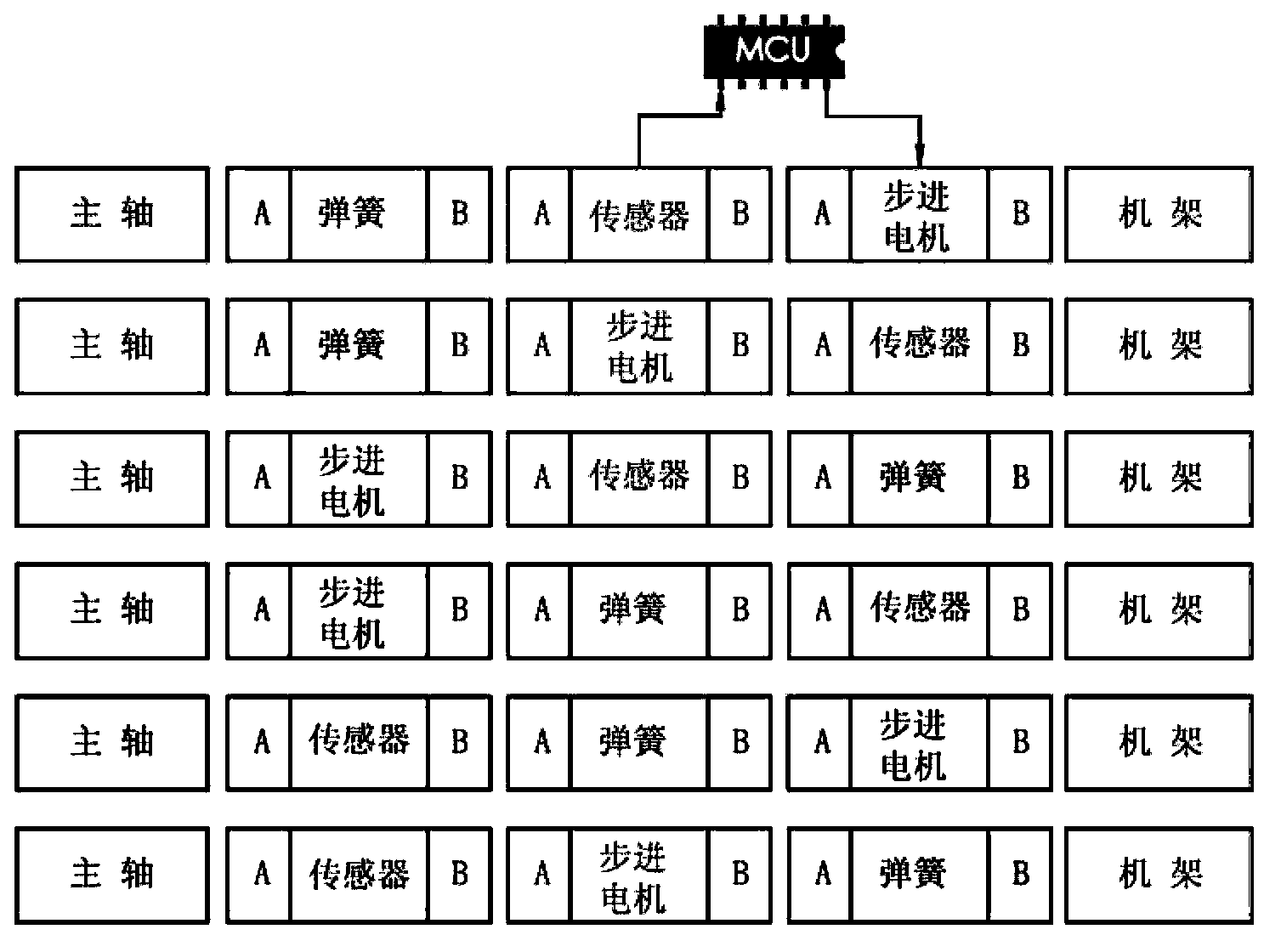

Method used

Image

Examples

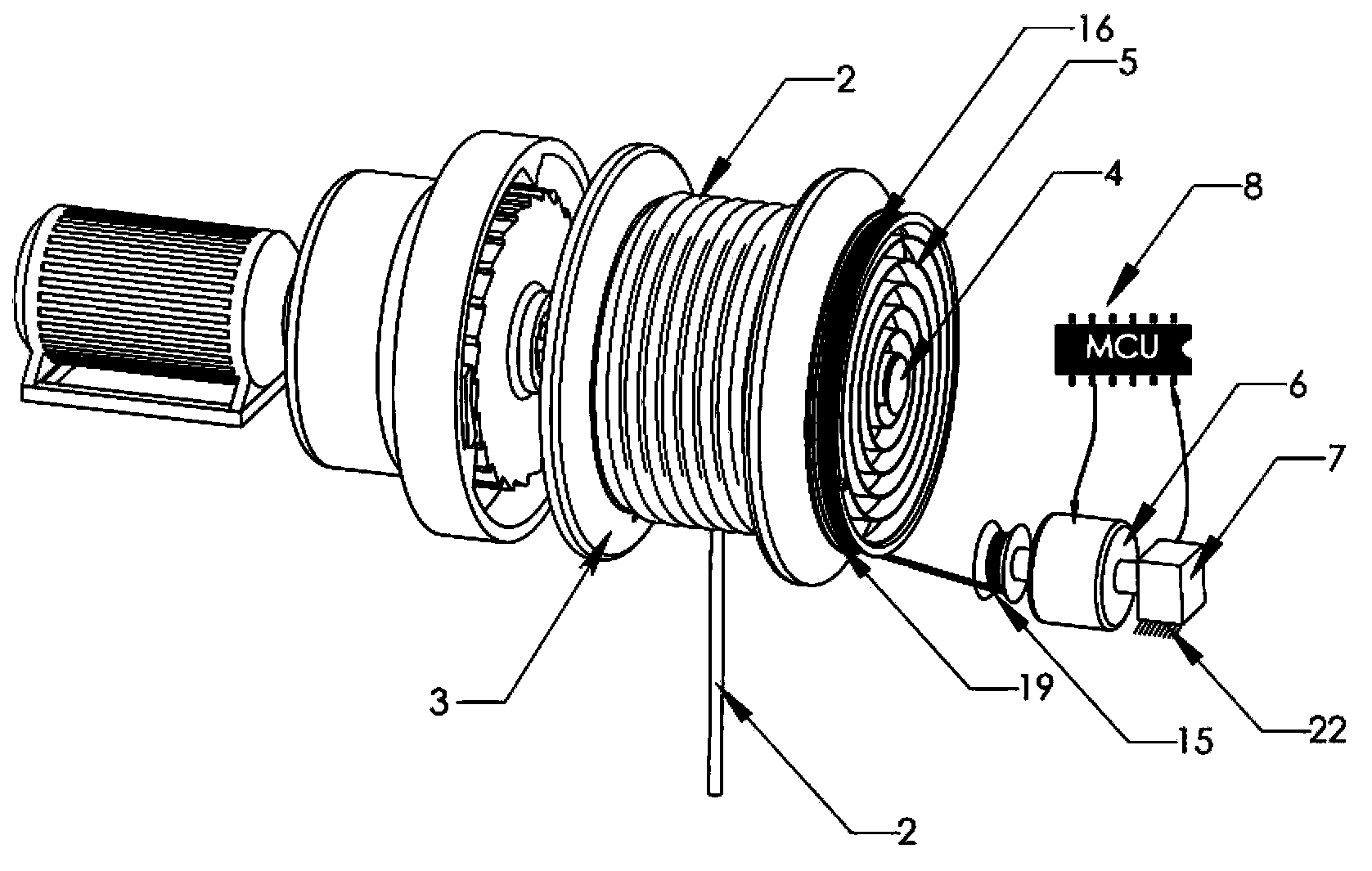

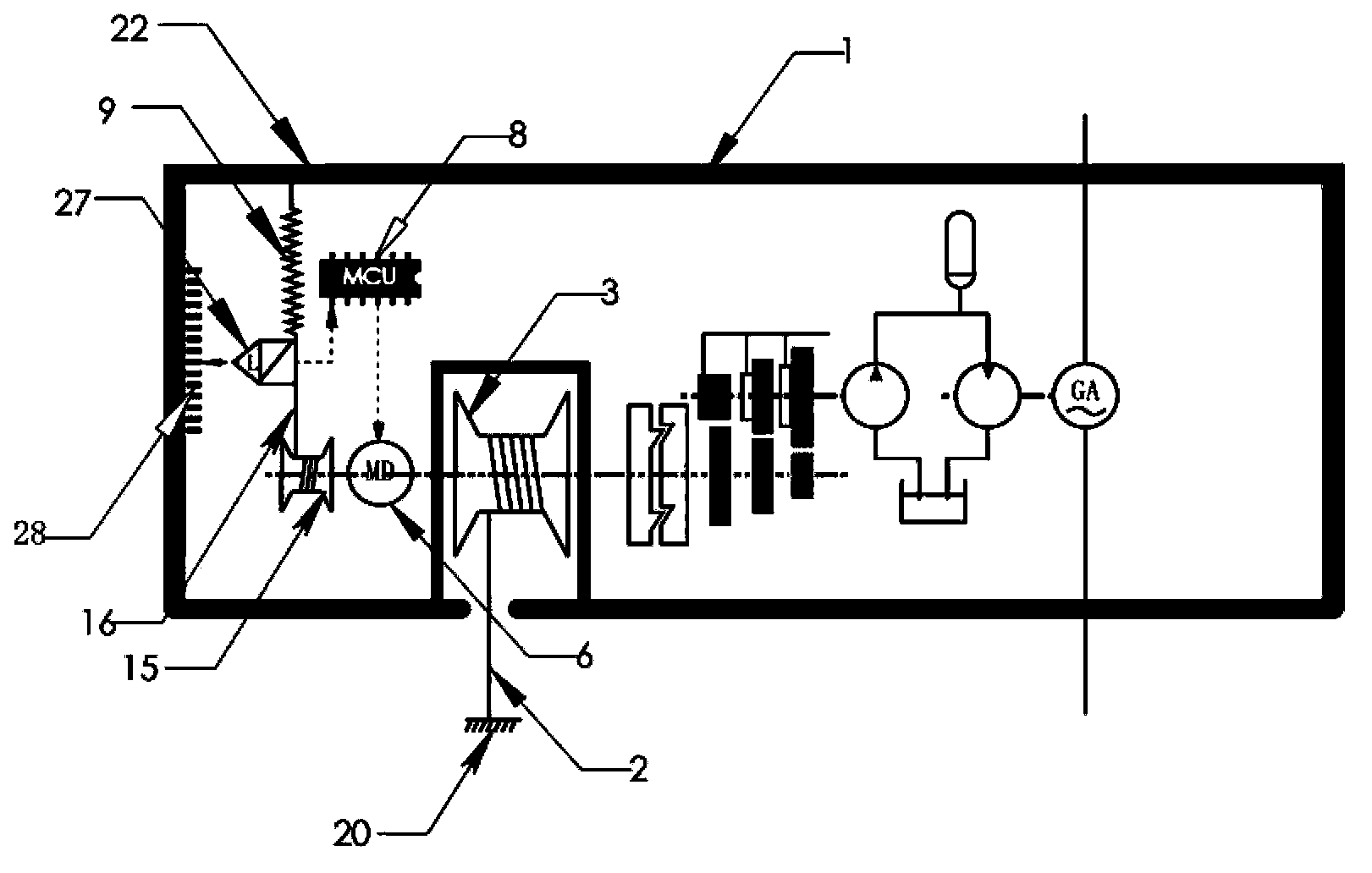

Embodiment Construction

[0081] Many wave power generation devices require return springs. For example, the wave power harvesting device of the one-way work method only uses the buoyancy of the wave to do work or after the wave lifts the floating body, it only uses its own gravity to do work, while the return stroke requires other forces. To reset, some rely on counterweights, and some use springs to reset. Those that use spring reset, such as the patent application CN101963125A floating body-based rope wheel wave power generation system, and the patent application CN2099205U wave power generation prime mover, both of which use the upward buoyancy and thrust to do work during the rising process of the floating body, and this process is also tightened. In the process of falling, the elastic potential energy of the spring is released to retract the rope. In the patent application 2012103827619 oscillating piston wave power generation system, when the wave height exceeds the stroke of the hydraulic cylin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com