Continuously variable transmission

A continuously variable transmission and regulator technology, applied in belt/chain/gear, mechanical equipment, transmission, etc., can solve the problems of high transmission efficiency, low transmission power, and high cost, and achieve precise control, easy maintenance, and simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

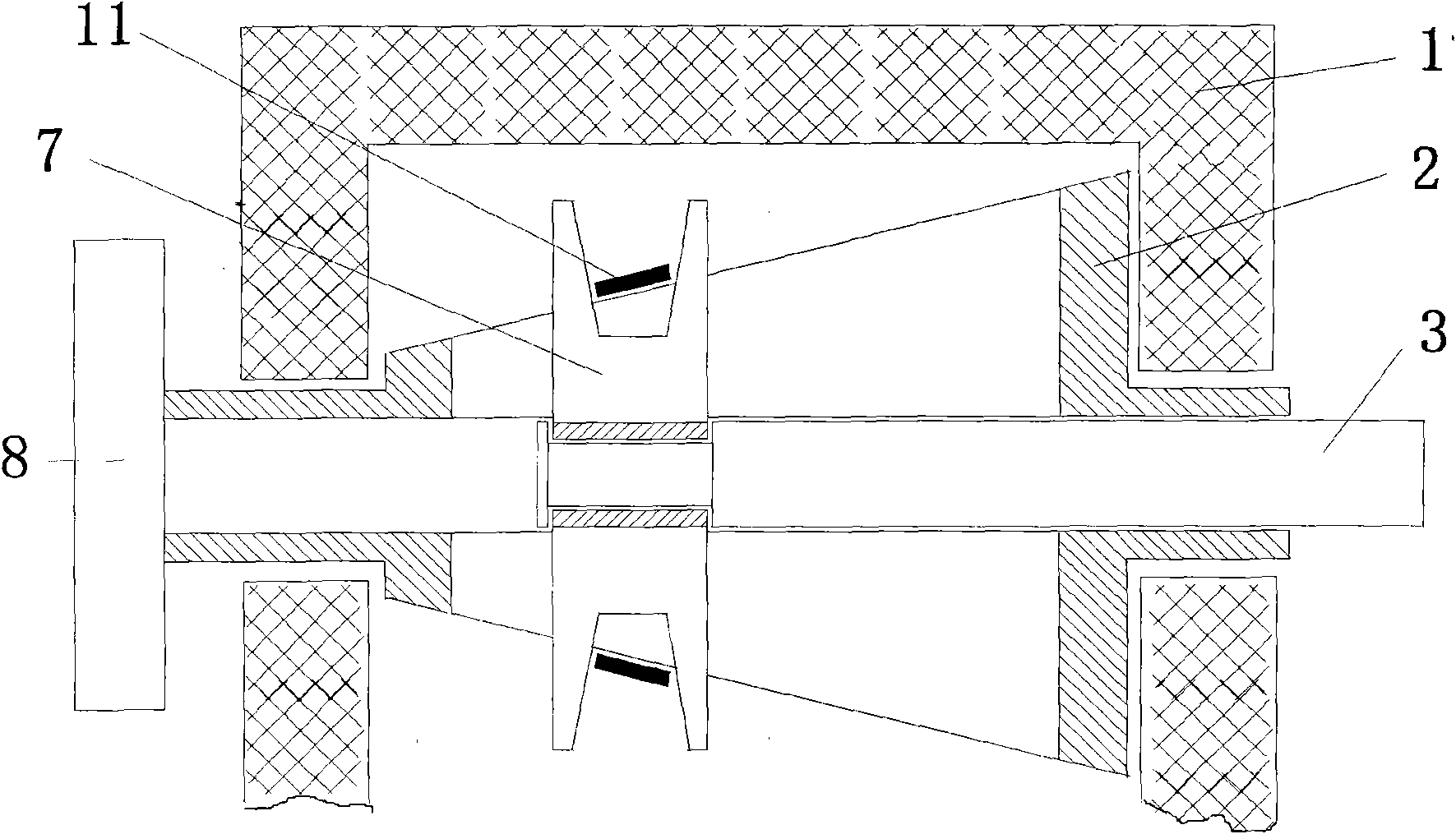

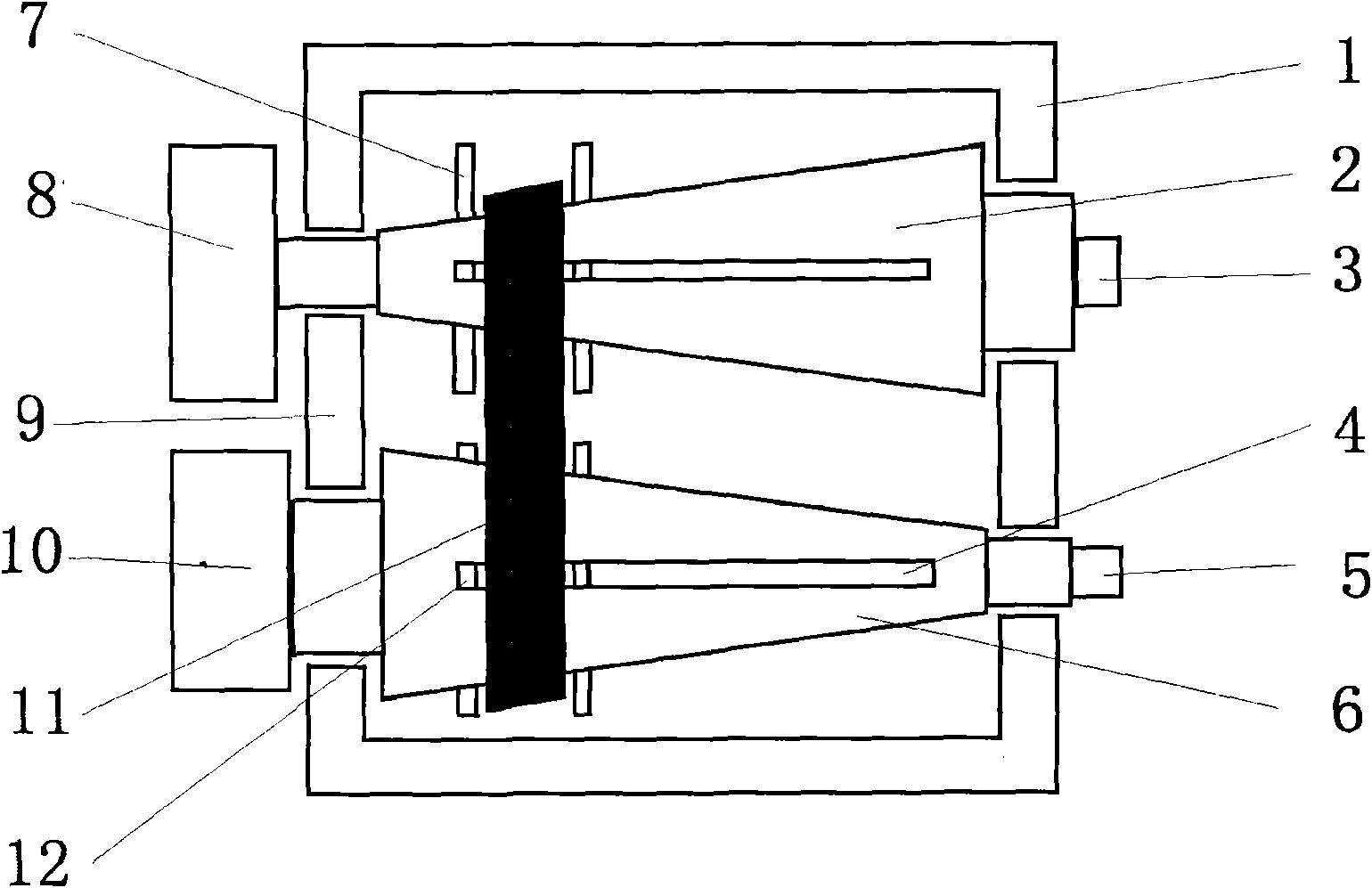

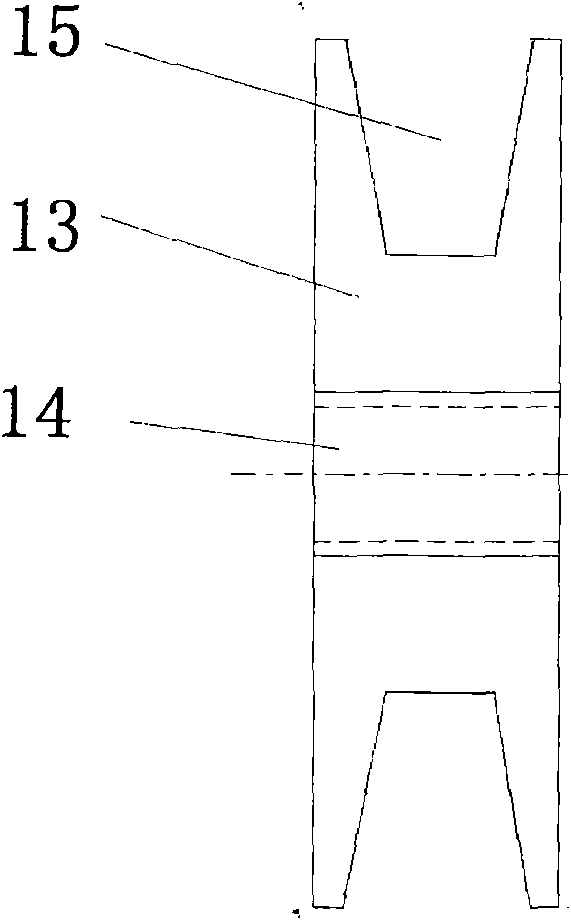

[0014] Such as figure 2 As shown, this is a schematic diagram of the structure of the CVT of the present invention. The input wheel 2 and the output wheel 6 are all conical wheels, and a transmission belt 11 is connected in the middle, and the transmission belt 11 is stuck in the middle of the V-shaped regulator 7 . When adjusting the input-output transmission ratio, just move the adjustment control lever 3 and the adjustment control lever 5 to the right, and at this time, under the drive of the V-shaped regulators 7 and 12, the transmission belt 11 moves along the axial direction of the input wheel 2 and the output wheel 6. Moving to the right, the effective action wheel diameter of the input wheel 2 becomes larger, the effective action wheel diameter of the output wheel 6 becomes smaller, and the input-output transmission ratio becomes larger, otherwise the input-output transmission ratio decreases. 8 is driving drive wheel, and 10 is passive drive wheel.

[0015] Such as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com