Fault diagnosis method for rolling bearing

A rolling bearing and fault diagnosis technology, applied in the direction of mechanical bearing testing, measuring devices, instruments, etc., to achieve the effect of automatic fault diagnosis and detection, reducing errors and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0023] Embodiment 1: In the rolling bearing fault diagnosis method of this embodiment, the parameters of the faulty rolling bearing are as follows: (1) The contact angle of the rolling bearing: 0°; (2) The rolling element diameter of the rolling bearing: 15mm; (3) The number of rolling elements of the rolling bearing : 18 pieces; (4) The pitch diameter of the rolling bearing is 104mm; (5) During the high-frequency sampling, the rotating speed of the rolling bearing is 499rpm, and the fault type is pitting failure of the outer ring. The sensor selected in this embodiment is a piezoelectric sensor, and the piezoelectric sensor is arranged on the outer ring of the rolling bearing to prepare for the subsequent steps.

[0024] The method in the present invention carries out the step of fault diagnosis to the fault rolling bearing in the present embodiment: as follows figure 1 shown.

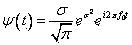

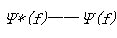

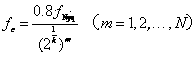

[0025] A After fixing the piezoelectric sensor on the outer ring of the rolling bearing in this e...

Embodiment approach 2

[0050]Embodiment 2: The rolling bearing fault diagnosis method of this embodiment, the parameters of the fault rolling bearing in this embodiment are as follows: (1) The contact angle of the rolling bearing: 0°; (2) The rolling body diameter of the rolling bearing: 15mm; (3) The rolling bearing The number of rolling elements: 18; (4) The pitch diameter of the rolling bearing: 104mm; (5) During the high-frequency sampling, the rotating speed of the rolling bearing was 749rpm, and the fault type was pitting failure of the outer ring. The sensor selected in this embodiment is a piezoelectric sensor, and the piezoelectric sensor is arranged on the outer ring of the rolling bearing to prepare for the subsequent steps.

[0051] The method in the present invention carries out the step of fault diagnosis to the faulty rolling bearing in this embodiment:

[0052] A After fixing the piezoelectric sensor on the outer ring of the rolling bearing in this embodiment, high-frequency sampling...

Embodiment approach 3

[0077] Embodiment 3: The rolling bearing fault diagnosis method of this embodiment, the parameters of the fault rolling bearing are as follows: (1) The contact angle of the rolling bearing: 0°; (2) The diameter of the rolling element of the rolling bearing: 15mm; (3) The number of rolling elements of the rolling bearing : 18 pieces; (4) The pitch diameter of the rolling bearing is 104mm; (5) During high-frequency sampling, the rotating speed of the rolling bearing is 1001rpm, and the fault type is pitting failure of the outer ring. The sensor selected in this embodiment is a piezoelectric sensor, and the piezoelectric sensor is arranged on the outer ring of the rolling bearing to prepare for the subsequent steps.

[0078] The steps of applying the method of the present invention to carry out fault diagnosis on the faulty rolling bearing in this embodiment are:

[0079] A After fixing the piezoelectric sensor on the outer ring of the rolling bearing in this embodiment, high-fre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com