Seepage failure testing device and method for seam pipeline between pipe bags and dam bags

A destructive test and tube-bag dam technology, which is applied in the direction of measuring devices, soil material testing, material inspection products, etc., can solve the problems of dam safety hazards, seepage damage, etc., and achieve the effects of low processing cost, convenient operation, and simple installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

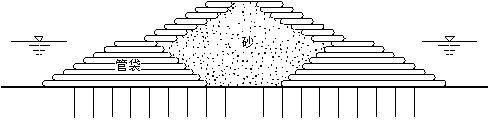

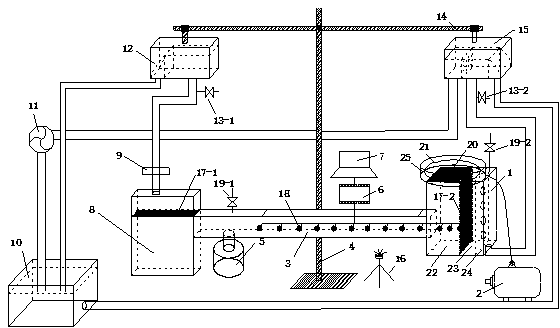

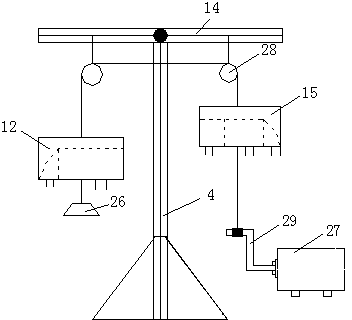

[0022] The technical scheme of the present invention is described in detail below in conjunction with accompanying drawing:

[0023] Such as figure 2 As shown, a pipe-bag-dam-bag seam pipeline penetration damage test device includes a support 4, and a cantilever 14 is arranged horizontally on the upper part of the support 4. One end of the cantilever 14 is connected to the water outlet tank 12, and the other end is connected to the water inlet tank 15; the water outlet tank 12 The lower end of the hose is connected to the suspended mass sand collection tank 8, the lower end hose of the water inlet tank 15 is connected to the sand tank 1, the suspended mass sand collection tank 8 and the sand tank 1 are connected to the water tank 3, and is close to the suspended mass sand collection tank 8 The water tank 3 on one side is connected with the moving mass sand collection tank 5, and the pipe bag fabric is pasted on the inner wall of the water tank 3, and several water pressure se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com